Measuring tool for rectifier channel and method for measuring rectifier channel

A rectifier and channel technology, applied in the field of rectifier channel measuring tools and measuring rectifier channels, can solve the problems of uncontrolled size and reduced channel area, and achieve the effects of improving performance, ensuring processing quality, and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

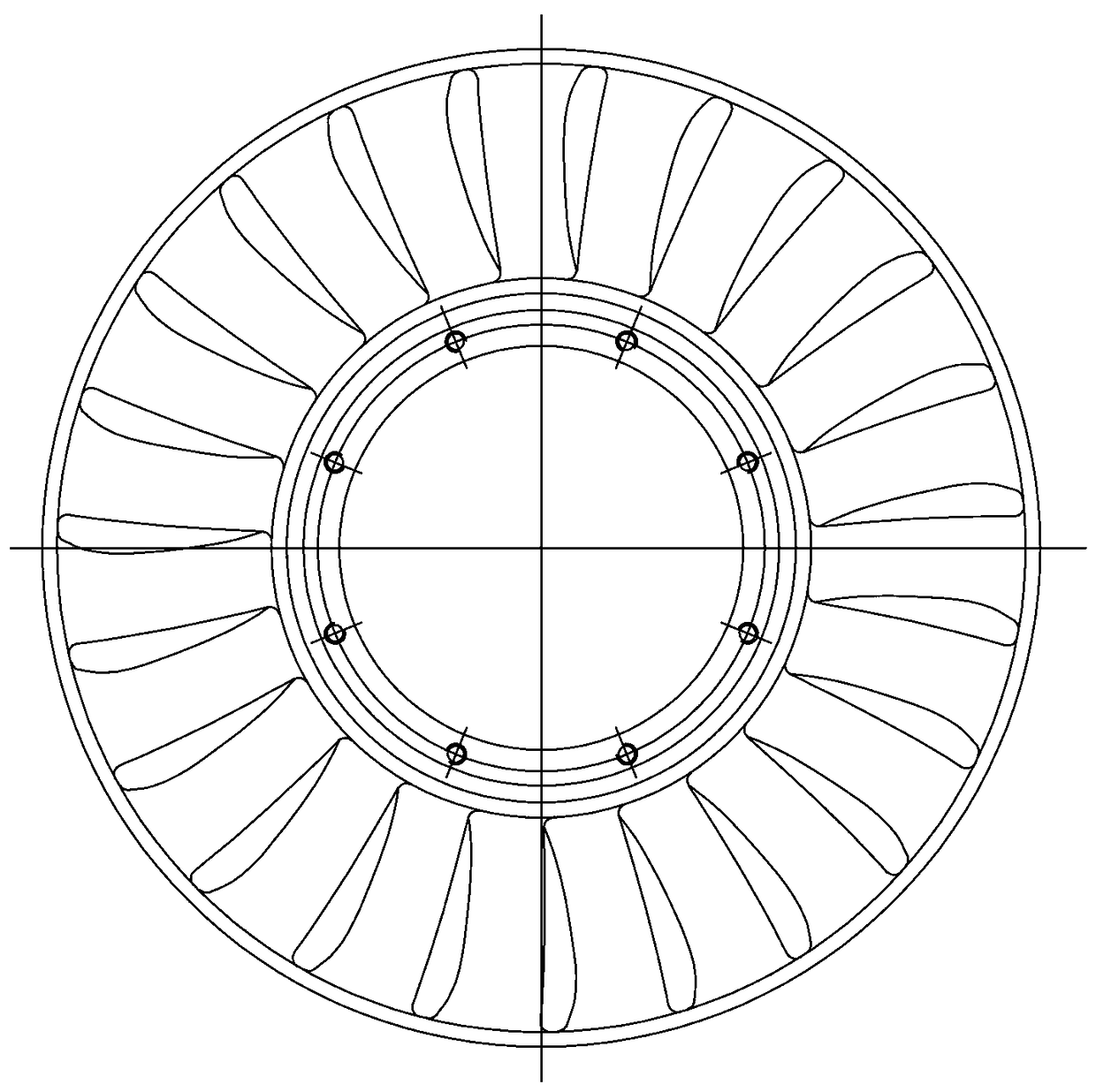

Image

Examples

Embodiment Construction

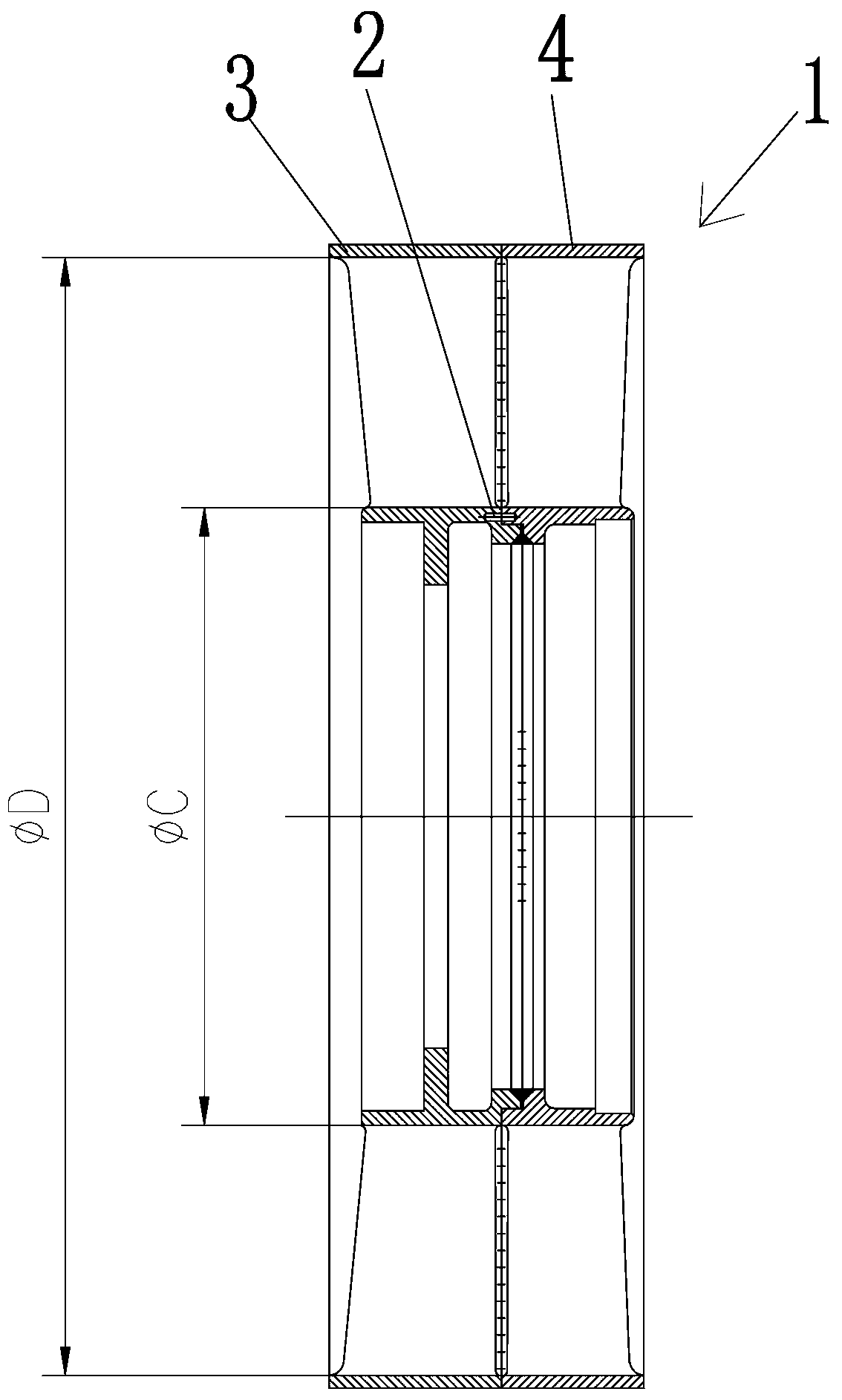

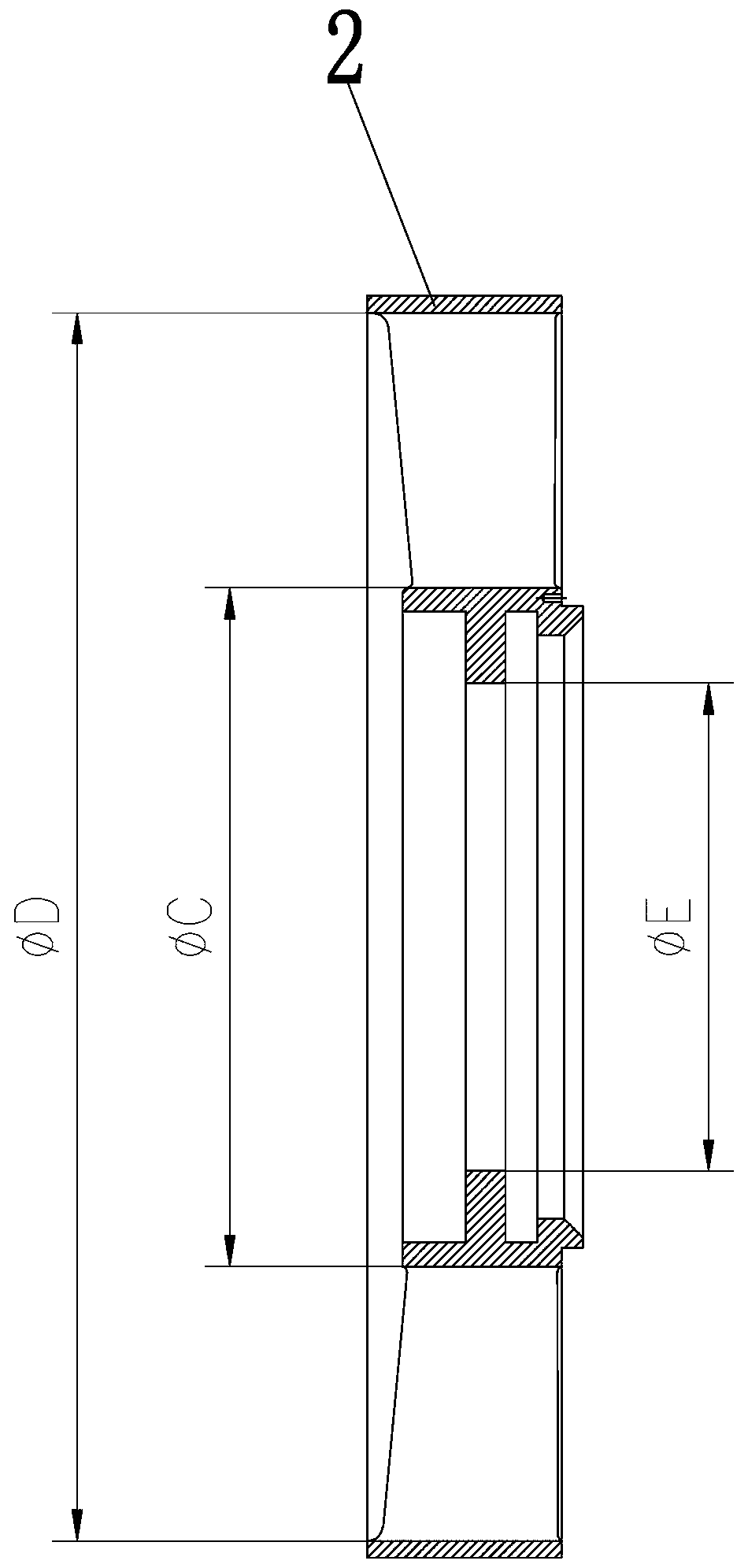

[0021] like Image 6 , the measuring tool for the rectifier passage of the present embodiment includes an L-shaped base, a mandrel 13, a shaft sleeve 14 and a floating counter part 17; the base is welded by a horizontal base 11 and a riser 12, and the riser 12 is vertically fixed on the horizontal On one side of the base 11, there is a horizontal through hole at a certain distance from the base on the riser 12; the mandrel 13 includes a threaded part, a transfer part, and a positioning part; the threaded part and the transfer part pass through the horizontal hole and connect the mandrel 13 is connected to the vertical plate 12, the transfer point is matched with the horizontal hole on the vertical plate 12, and the matching gap is 0-0.03mm; At the positioning of the mandrel, the matching clearance is 0.02-0.06mm, and the centering position of the sleeve 14 is matched with the inner hole of the part (the inner ring of the front or rear rectifier, or the inner ring of the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com