Detection device and method for large-particle occluded foreign substances in steel

A technology of large particle inclusion and detection device, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, which can solve the problems of low detection efficiency, sample damage, and inability to detect full volume, and achieves a simple test method and high detection efficiency. , the effect of saving human capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Type of steel: GCr15 bearing steel (round steel)

[0086] Steel specifications: diameter 60mm

[0087] 1. Preparation of artificial defect samples

[0088] The sample is directly cut from the rolled bar, and the length of the sample is 300mm.

[0089] Pretreatment: Normalizing heat treatment of the sample (purpose: uniform structure, reducing noise interference, improving signal-to-noise ratio), surface turning and polishing of the sample after heat treatment (purpose: preventing detection interference caused by rough surface), turning , After polishing treatment, ellipticity≤1%d, surface roughness Ra≤2.0μm.

[0090] Drilling: 3 holes are machined at the same linear position on the side wall of the round bar For flat-bottomed holes, the depths of the three flat-bottomed holes are: 5mm from the upper surface, 5mm from the center, and 5mm from the lower surface.

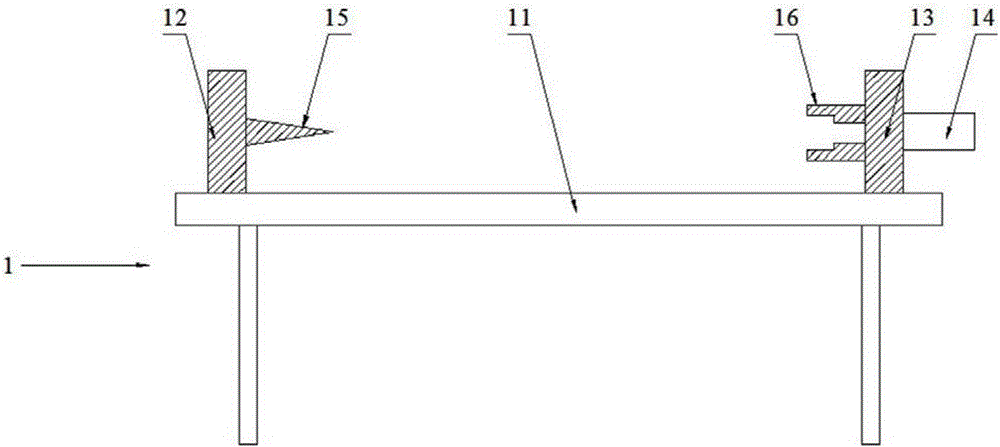

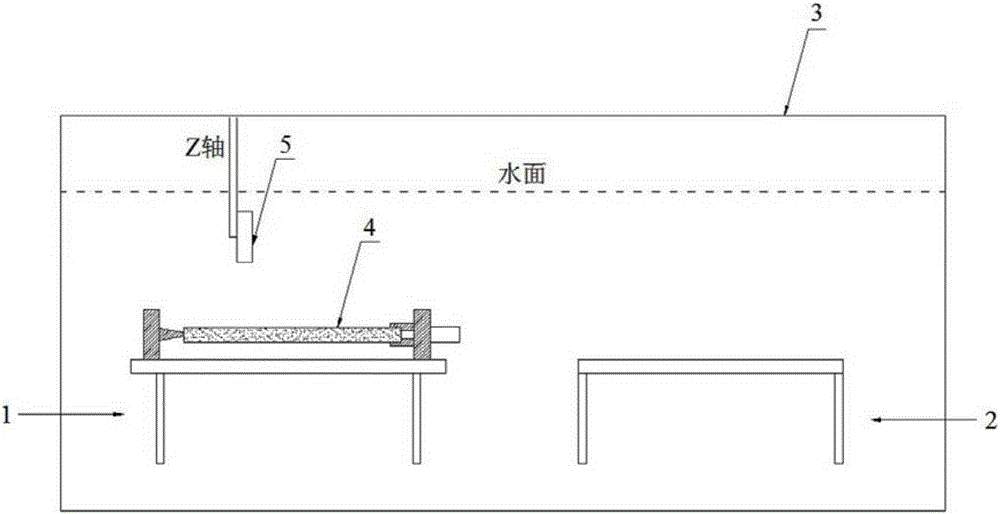

[0091] 2. Install the sample

[0092] Punch a hole at one end of the artificial defect sample with a de...

Embodiment 2

[0107] Type of steel: SCM822H automotive steel (square steel)

[0108] Steel specifications: length 150mm, width 150mm, thickness 60mm

[0109] 1. Preparation of artificial defect samples

[0110] The sample is directly cut from the rolled steel, the length of the sample is 200mm, and then processed into a sample with a length of 150mm, a width of 150mm, and a thickness of 60mm.

[0111] Pretreatment: First, normalize heat treatment on the sample, then turn and polish the surface of the sample (turning and polishing should be carried out on the detection surface and the opposite surface), and the surface roughness after treatment is Ra≤2.0μm.

[0112] Drilling: Make 3 Φ0.4mm flat-bottomed holes on the square steel. The center points of the 3 flat-bottomed holes are on a straight line, which is parallel to the rolling direction of the billet and steel plate. The depths of the 3 flat-bottomed holes are: 5mm from the upper surface, to the center, and 5mm from the lower surface....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com