Cylindrical hole boring device

A cylindrical hole and boring technology, which is applied in the direction of driving device, feeding device, boring/drilling, etc., can solve the problems of large ellipticity, poor rigidity, and difficult adjustment of cylindrical holes, so as to improve production efficiency and low manufacturing cost , The effect of simple clamping and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

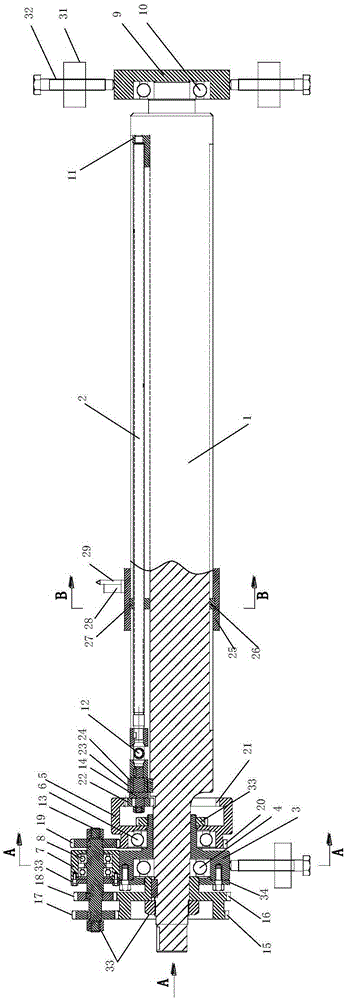

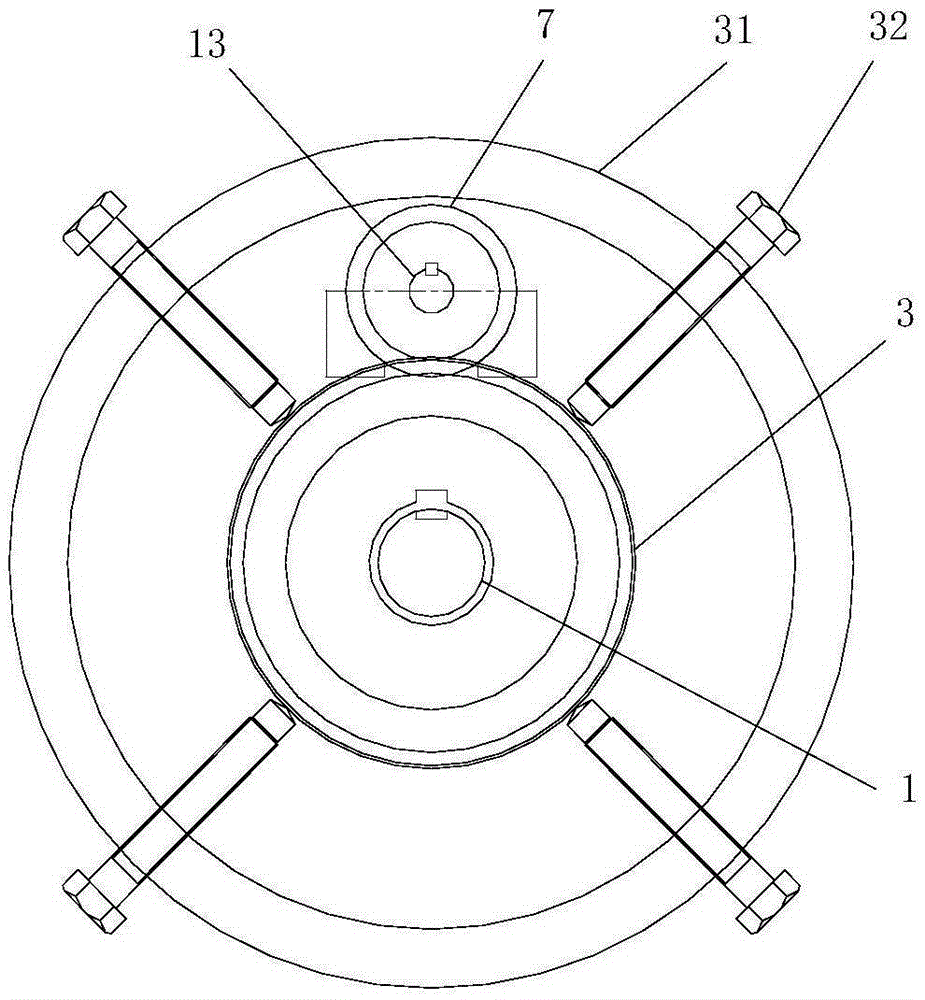

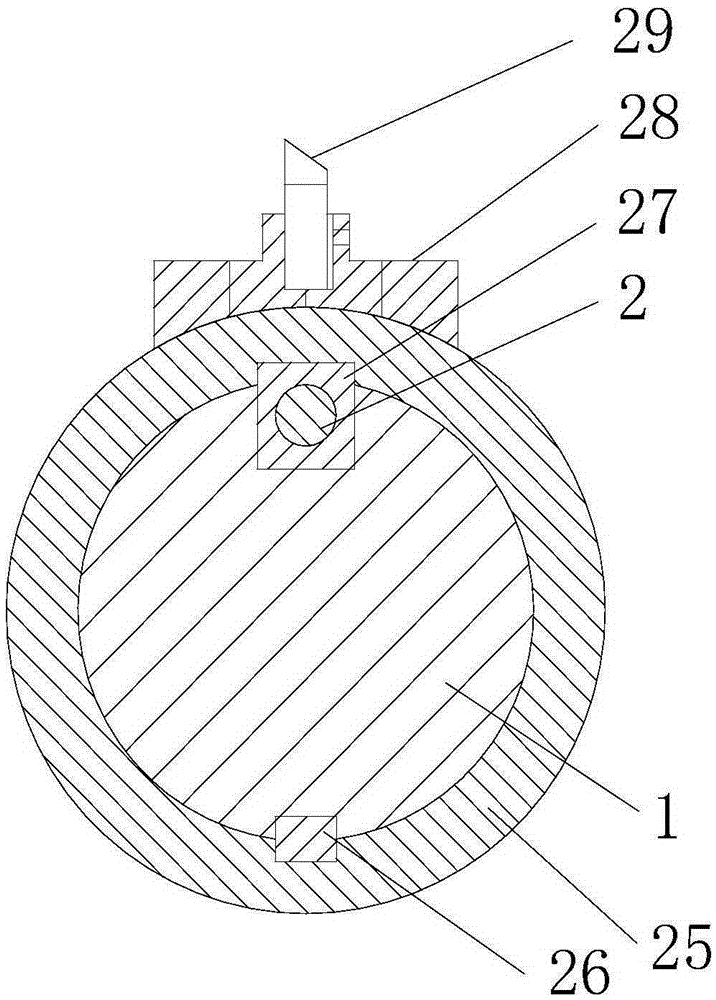

[0026] Such as Figure 1-3 As shown, a kind of cylindrical hole boring device of the present embodiment, motor, boring bar 1, support adjustment mechanism, power transmission system, transmission screw rod 2 and tool feeding system; Described motor transmits power to boring bar 1; Boring bar One end of 1 is supported by ball bearing I4 in bearing housing I3, and the tail end is supported by ball bearing IV10 in bearing housing IV9. Bearing housing I3 and bearing housing IV9 are supported by a support adjustment mechanism, which can support and adjust boring bar 1 The center line is consistent with the center line of the processed workpiece; the outer circle of the boring bar 1 has a long chute; the transmission screw 2 is located in the chute of the boring bar 1, and one end is supported and fixed on the chute by the supporting bearing seat 11 The tail end, the other end is connected with the power transmission system by the universal coupling 12, and the knife feeding system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com