A method for joint production of potassium sulfate and calcium chloride dihydrate

A joint production technology of calcium chloride dihydrate, applied in the direction of calcium/strontium/barium chloride, sulfate/bisulfate preparation, calcium/strontium/barium halide, etc., can solve repeated energy consumption and energy waste , large water evaporation, complex process and other problems, to achieve the effect of saving energy consumption and investment in process equipment, solving environmental problems, and reducing temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

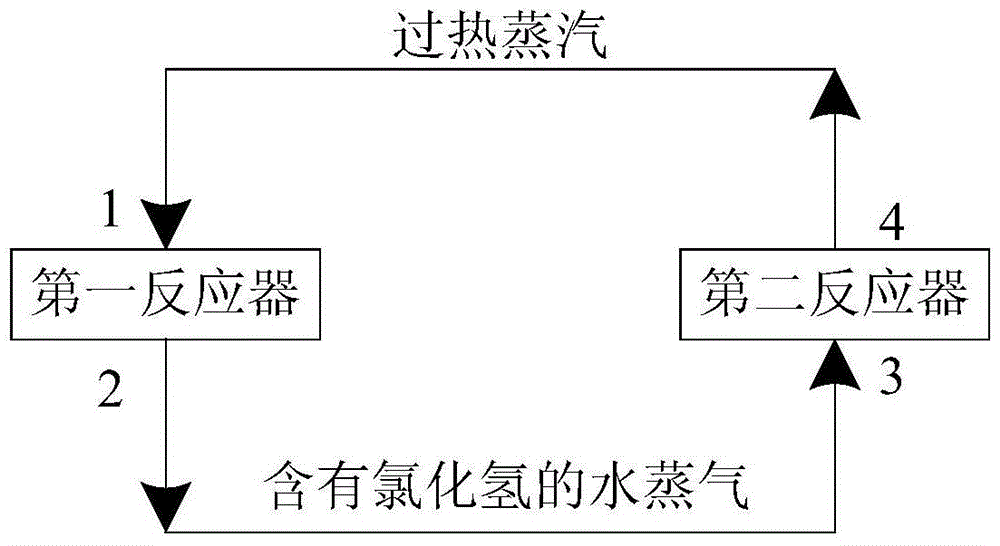

[0051] (1) 10mol Potassium Chloride and 5mol concentrated sulfuric acid (98wt%) are added to react in the first reactor, pass into superheated steam by the steam inlet 1 of the first reactor, the temperature control of superheated steam is 180 ℃, pressure control It is 0.13Mpa, after the steam is fully contacted with the reactant in the first reactor, the water vapor containing hydrogen chloride generated by the reaction is discharged from the steam outlet 2 of the first reactor;

[0052] (2) Add 5.1mol calcium oxide in the second reactor, the steam containing hydrogen chloride discharged by the steam outlet 2 of the first reactor enters in the second reactor through the steam inlet 3 of the second reactor, and wait to contain hydrogen chloride After the water vapor in the second reactor is fully contacted with the calcium oxide in the second reactor, calcium chloride dihydrate and superheated steam are obtained, and the superheated steam is discharged from the steam outlet 4 o...

Embodiment 2

[0054] (1) 20mol Potassium Chloride and 11mol concentrated sulfuric acid (98wt%) are joined in the first reactor to react, pass into superheated steam by steam inlet 1 of the first reactor, superheated steam temperature is controlled as 220 ℃, and pressure is controlled as 0.6Mpa. After the steam is in full contact with the reactant in the first reactor, the water vapor containing hydrogen chloride generated by the reaction is discharged from the steam outlet 2 of the first reactor;

[0055] (2) The calcium oxide that adds 11.7mol is in the second reactor, and the water vapor that contains hydrogen chloride discharged by the steam outlet 2 of the first reactor enters in the second reactor by the steam inlet 3 of the second reactor, and waits to contain After the water vapor of hydrogen chloride is fully contacted with the calcium oxide in the second reactor, calcium chloride dihydrate and superheated steam are obtained, and the superheated steam is discharged from the steam ou...

Embodiment 3

[0057] (1) 30mol Potassium Chloride and 13.6mol concentrated sulfuric acid (98wt%) are added to react in the first reactor, pass into superheated steam by steam inlet 1 of the first reactor, the temperature control of superheated steam is 270 ℃, pressure The control is 1.2Mpa. After the steam is in full contact with the reactant in the first reactor, the water vapor containing hydrogen chloride generated by the reaction is discharged from the steam outlet 2 of the first reactor;

[0058] (2) Add 18mol of calcium oxide in the second reactor, the steam containing hydrogen chloride discharged by the steam outlet 2 of the first reactor enters in the second reactor through the steam inlet 3 of the second reactor, and wait to contain hydrogen chloride After the water vapor in the second reactor is fully contacted with the calcium oxide in the second reactor, calcium chloride dihydrate and superheated steam are obtained, and the superheated steam generated by the reaction is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com