High-performance refrigeration lubricating oil composition

A lubricating oil composition and product technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve problems such as refrigerated lubricating oil leaving, insufficient amount of refrigerating lubricating oil, compressor failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

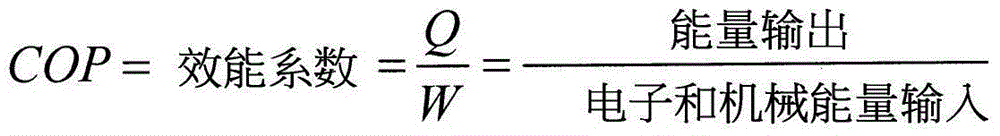

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The synthesis method of the polyol ester product (POE) of the present invention comprises an esterification step and a purification step.

[0047] Esterification step: an appropriate amount of one or more linear or branched saturated or unsaturated C 4-20 The fatty acid is reacted with one, two or three polyols selected from tripentaerythritol, dipentaerythritol or pentaerythritol in the presence (or absence) of a catalyst. Depending on the starting material and catalyst, the reaction temperature is about 150 to 250°C, preferably 180 to 240°C, more preferably 200 to 230°C, until the hydroxyl value is lower than 10mgKOH / g, preferably 5mgKOH / g g or less, more preferably 3 mgKOH / g or less.

[0048] Commonly used catalysts include stannous oxalate, stannous oxide, tetrabutyl titanate, tripropyl titanate or methanesulfonic acid.

[0049] Purification steps:

[0050] Moisture removal: Dry the system under high vacuum to remove moisture to below 50ppm.

[0051] Removal of ...

Embodiment 1

[0073] Embodiment 1.TriPE+(iC9, MBA, nC5)

[0074] Raw material: tripentaerythritol (TriPE), and fatty acid: isoC9 (3,5,5-trimethylhexanoic acid)+MBA (2-methylbutyric acid)+nC5 (n-valeric acid) (wt%=25%: 60 %: 15%)

[0075] Additives: tricresyl phosphate 1%, 2,6-di-tert-butyl-4-methylphenol 200ppm, methyl benzotriazole derivatives 200ppm

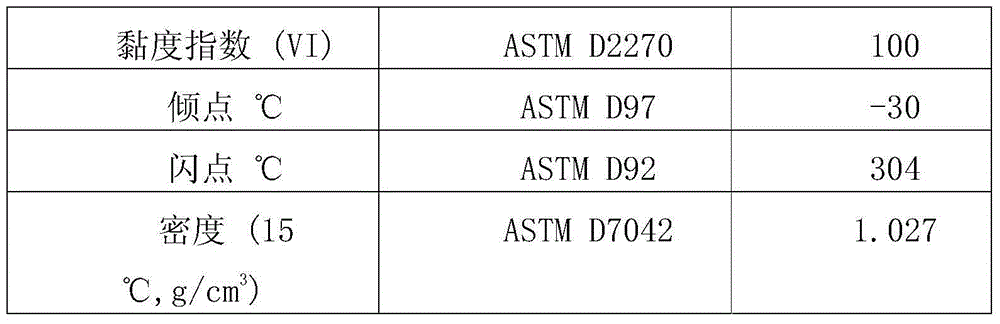

[0076] Basic physical properties:

[0077]

[0078]

Embodiment 2

[0079] Example 2. Mixed ester 1

[0080] Synthetic ester 1: TriPE+neo10 (neodecanoic acid)+MBA, wherein neo10:MBA=80:20 (weight%)

[0081] Synthetic ester 2: dipentaerythritol (DiPE) + MBA

[0082] Mixed ester 1 = synthetic ester 1 (% by weight = 45%) + synthetic ester 2 (% by weight = 55%)

[0083] Additives: tricresyl phosphate 1%, 2,6-di-tert-butyl-4-methylphenol 200ppm, methyl benzotriazole derivatives 200ppm

[0084] Basic physical properties:

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com