A roasting defluorination device and process

A roasting and defluorination technology, which is applied in the processing field of mineral raw materials, can solve problems such as the inability to utilize high-temperature tail gas energy, and achieve the effects of promoting migration and transformation, preventing sintering and ring formation, and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

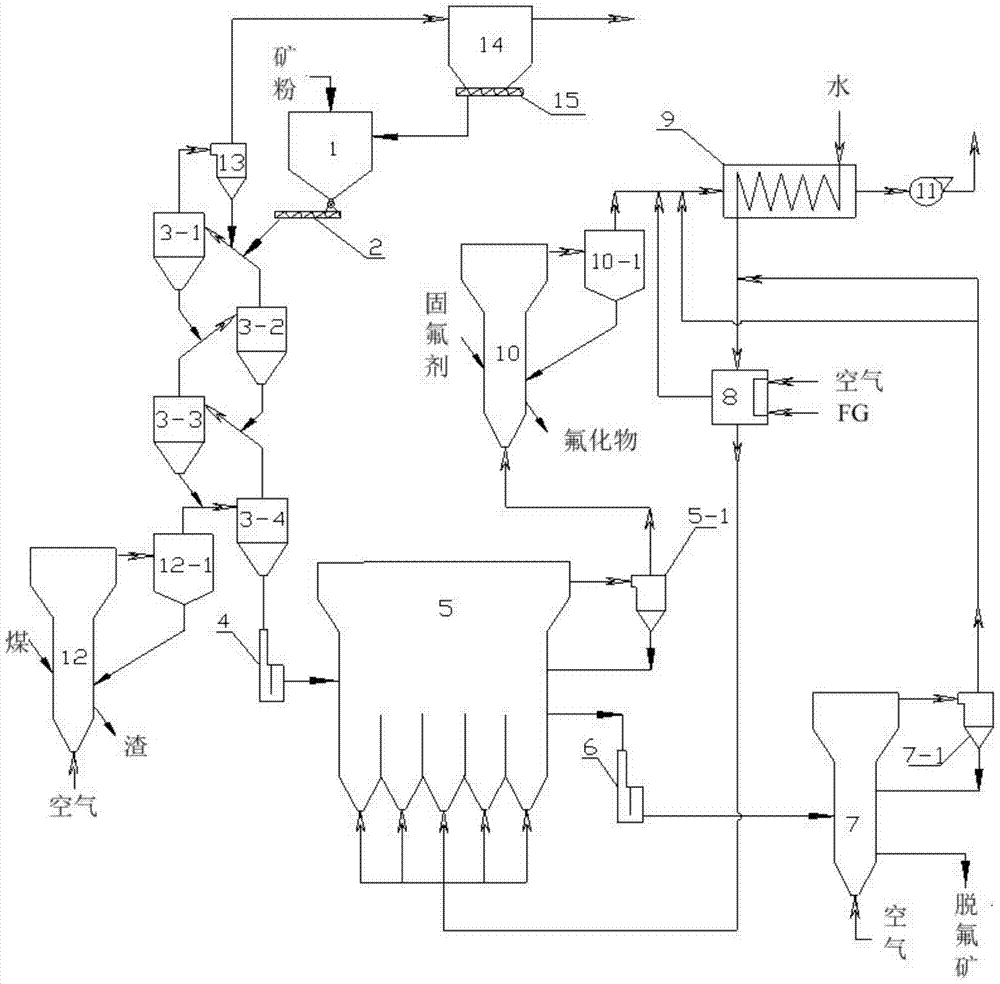

[0108] figure 1 Provides a structural schematic diagram of a lepidolite fluidized bed roasting defluorination device, the device includes: feeding system, mineral powder preheating system, fluidized roasting system, water vapor preheating system, gas absorption system, cooling system and ventilation system.

[0109] The feeding system is used to transport lepidolite mineral powder to the mineral powder preheating system, including hopper 1 and screw feeder 2;

[0110] Mineral powder preheating system is used to preheat lepidolite ore to make its temperature reach 800-850℃, including coal-fired fluidized bed 12, coal-fired fluidized bed separator 12-1, four-stage cyclone preheater and cyclone separation 13, the four-stage cyclone preheater includes the first-stage cyclone preheater 3-1, the second-stage cyclone preheater 3-2, the third-stage cyclone preheater 3-3 and the fourth-stage cyclone preheater connected in sequence Preheater 3-4;

[0111] The fluidized roasting syste...

Embodiment 2

[0132] Utilize the device that embodiment 1 provides to carry out lepidolite roasting defluorination, comprise the steps:

[0133] (1) Add lepidolite ore powder into the hopper 1, send it to the fourth-stage cyclone preheater 3-4 through the screw feeder 2, and pass through the third-stage cyclone preheater 3-3 and the second-stage cyclone preheater successively. The heater 3-2 and the first-stage cyclone preheater 3-1 exchange heat with the high-temperature hot flue gas from the coal-fired fluidized bed 12; at the same time, the steam boiler 9 and the combustion chamber 8 generate high-temperature steam;

[0134] (2) The temperature of the preheated lepidolite ore powder rises to 800°C, and is sent into the fluidized bed roaster 5, where it is fully contacted with the high-temperature water vapor (900°C) from the combustion chamber 8 to carry out the roasting defluorination reaction, and its roasting The reaction conditions are: the fluidized bed roaster 5 is a 5-stage fluidi...

Embodiment 3

[0146] Utilize the device that embodiment 1 provides to carry out lepidolite roasting defluorination, comprise the steps:

[0147] (1) Add lepidolite ore powder into the hopper 1, send it to the fourth-stage cyclone preheater 3-4 through the screw feeder 2, and pass through the third-stage cyclone preheater 3-3 and the second-stage cyclone preheater successively. The heater 3-2 and the first-stage cyclone preheater 3-1 exchange heat with the high-temperature hot flue gas from the coal-fired fluidized bed 12; at the same time, the steam boiler 9 and the combustion chamber 8 generate high-temperature steam;

[0148] (2) The temperature of the preheated lepidolite ore powder rises to 850°C, and it is sent into the fluidized bed roaster 5, and fully contacts with the high-temperature water vapor (1000°C) from the combustion chamber 8 to carry out the roasting defluorination reaction, and the roasting The reaction conditions are: the fluidized bed roaster 5 is a three-stage fluidiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com