Astigmatic, light-absorbing, heat-radiation regulating cloth and its preparation method

A technology of thermal radiation and astigmatism, which is applied in the agricultural field, can solve the problems of black light-shielding plastic film without heat insulation function, poor shading rate, and increased ambient temperature, so as to achieve good astigmatism and heat insulation function, good astigmatism coverage, and good cooling The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Astigmatism, light-absorbing, and heat-radiation regulating cloth is composed of three parts: the astigmatism layer, the support layer and the light-absorbing layer.

[0060] The astigmatism layer mainly contains broad-spectrum light-transmitting, low-refractive-index film-forming resin materials and high-refractive-index micropowder materials;

[0061] The support layer is mainly made of synthetic fiber cloth with high breaking strength, smooth surface, poor hygroscopicity and high infrared emissivity;

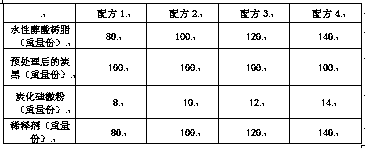

[0062] The light-absorbing layer mainly contains film-forming resin materials with high infrared absorption rate, good thermal conductivity and heat-conducting micro-powder materials, and broad-spectrum light-absorbing and infrared-emitting micro-powder materials.

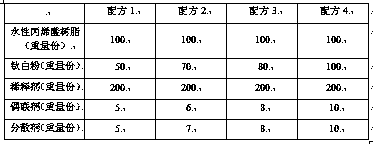

[0063] 2. The astigmatism layer can be composed of rutile titanium dioxide with high transparency, good light transmission performance, low far-infrared absorption rate, good film-forming and mechanical ...

Embodiment 2

[0078] 1. Preparation of astigmatism layer:

[0079] 1. Polymers that can be used for astigmatism coating

[0080] Materials that can be used for astigmatism coatings should require low sunlight absorption rate, and the resin used should preferably contain C-O-C, C=C, -OH and other groups as little as possible. At the same time, considering the ability to combine with the support layer (fiber), the available materials are as follows: acrylic resin, polyester resin, polyurethane resin, alkyd resin, polymethacrylic resin.

[0081] Among the above materials, acrylic resin has low film-forming property, adhesiveness, light transmittance and low refractive index, and can be combined with high refractive index micropowder materials to form a high scattering ability. At the same time, the price is relatively low, preferably water-based acrylic resin.

[0082] Mixing method of titanium dioxide and coating material

[0083] There are two ways to mix titanium dioxide and coating mate...

Embodiment 3

[0138] An astigmatism, light-absorbing, heat-radiation regulating cloth and a preparation method thereof, comprising the following steps:

[0139] Step 1: Selection of base cloth

[0140] Select high-strength polyester cloth, its technical indicators are:

[0141] Mass per unit area (g / m 2 ) 200

[0142] Breaking strength (longitudinal) KN / m 6.7

[0143] Breaking strength (lateral direction) KN / m 8.0

[0144] Elongation at break (longitudinal direction)% 88

[0145] Elongation at break (transverse direction)% 82

[0146] CBR bursting strength KN 1.1

[0147] Step 2: Pretreatment of carbon black:

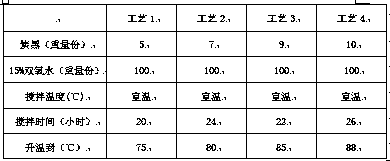

[0148] Use N-110 carbon black with a particle size of 11-19nm, add carbon black to 15% hydrogen peroxide, stir at room temperature, slowly raise the temperature, keep it for a period of time until the solution has no obvious bubbles, and set it aside for use. The specific process parameters are shown in Table 1. :

[0149] Table 1: Carbon black pretreatment process parameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com