Light-scattering and thermal-insulating thermal radiation regulating and controlling membrane for agricultural facilities and preparation method

一种热辐射、设施的技术,应用在植物学设备和方法、化学仪器和方法、应用等方向,能够解决隔热降温效果不显著、反射膜光损大、明晃白亮白亮污染等问题,达到隔热节能效果显著、良好散光隔热、良好散光遮盖的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

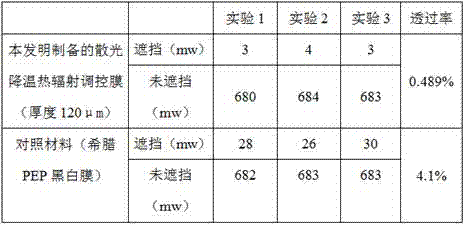

[0064] Example 1 A light astigmatism heat insulation thermal radiation control film

[0065]A light-scattering, heat-insulating, and heat-radiation regulating film for agricultural facilities is composed of a light-scattering layer and a light-absorbing radiation layer; the thickness ratio of the light-scattering layer and the light-absorbing radiation layer is 5:2.

[0066] The light scattering layer mainly contains broad-spectrum light-transmitting, low-refractive-index film-forming resin material and high-refractive-index micropowder material.

[0067] The light-absorbing and radiation-absorbing layer mainly contains film-forming resin materials that are highly bonded to the resin of the light-scattering layer, heat-conducting micropowder materials and light-absorbing heat radiation micropowders.

[0068] (1) The broad-spectrum light-transmitting, low-refractive-index film-forming resin material:

[0069] PVC, HDPE, LDPE, LLDPE and other resins can be used, preferably low-...

Embodiment 2

[0088] Embodiment 2 Light-scattering layer masterbatch formula

[0089] The light-scattering layer masterbatch is rutile titanium dioxide and LDPE (low-density polyethylene) masterbatch; the specific mass ratio of the light-scattering layer masterbatch raw materials is as follows:

[0090] Recipe one:

[0091] The specific mass ratio of masterbatch raw materials is as follows:

[0092] Rutile Titanium Dioxide 426 copies

[0093] Stearic acid YA-Ⅱ-200 type 30 parts

[0094] PE wax 27 parts

[0095] LDPE 320 parts

[0096] LLDPE 197 parts

[0097] Recipe 2:

[0098] Rutile titanium dioxide 426 parts

[0099] Phthalocyanine blue 0.6 parts

[0100] Stearic acid YA-Ⅱ-200 type 30 parts

[0101] PE wax 26.4 parts

[0102] LDPE 367 parts

[0103] LLDPE 150 parts

[0104] Formula 3: The specific mass ratio of masterbatch raw materials is as follows:

[0105] Rutile titanium dioxide 427 parts

[0106] PE wax 20 parts

[0107] Oleamide 23 parts

[0108] LDPE 333 parts ...

Embodiment 3

[0111] Embodiment 3 Masterbatch formulation of light-absorbing radiation layer

[0112] The light-absorbing radiation layer masterbatch is carbon black, silicon carbide micropowder, and LDPE (low-density polyethylene) masterbatch; the specific mass ratio of the light-absorbing radiation layer masterbatch raw materials is as follows:

[0113] Recipe one:

[0114] LDPE 48 parts

[0115] LLDPE 31 parts

[0116] 3 parts carbon black

[0117] Silicon carbide powder 11 parts

[0118] 2 parts of coupling agent

[0119] 1 part dispersant

[0120] 2 parts plasticizer

[0121] PE wax 3 parts

[0122] Recipe 2:

[0123] LDPE 46.5 parts

[0124] LLDPE 28 parts

[0125] PE wax 2 parts

[0126] Carbon black 2.5 parts

[0127] Silicon carbide powder 13 parts

[0128] 3 parts of coupling agent

[0129] dispersant 3 parts

[0130] 2 parts plasticizer

[0131] Recipe three:

[0132] LDPE 49 parts

[0133] LLDPE 27 parts

[0134] 3 parts carbon black

[0135] Silicon carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com