A light astigmatism heat insulation thermal radiation control film and preparation method thereof

A technology of thermal radiation and astigmatism, which is applied in botany equipment and methods, chemical instruments and methods, flat products, etc., can solve the problems of large light loss of reflective film, bright and white pollution, and insignificant heat insulation and cooling effect. Achieve good astigmatism and heat insulation, good astigmatism cover, heat insulation and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

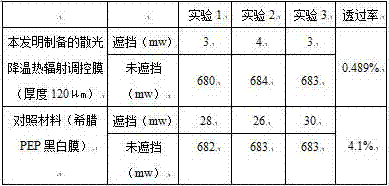

[0063] Example 1 A light astigmatism heat insulation thermal radiation control film

[0064] A light-scattering, heat-insulating, heat-radiation regulating film is composed of a light-scattering layer and a light-absorbing radiation layer; the thickness ratio of the light-scattering layer and the light-absorbing radiation layer is 5:2.

[0065] The light scattering layer mainly contains broad-spectrum light-transmitting, low-refractive-index film-forming resin material and high-refractive-index micropowder material.

[0066] The light-absorbing and radiation-absorbing layer mainly contains film-forming resin materials that are highly bonded to the resin of the light-scattering layer, heat-conducting micropowder materials and light-absorbing heat radiation micropowders.

[0067] (1) The broad-spectrum light-transmitting, low-refractive-index film-forming resin material:

[0068] PVC, HDPE, LDPE, LLDPE and other resins can be used, preferably low-density polyethylene (LDPE), the ...

Embodiment 2

[0087] Embodiment 2 Light-scattering layer masterbatch formula

[0088] The light-scattering layer masterbatch is rutile titanium dioxide and LDPE (low-density polyethylene) masterbatch; the specific mass ratio of the light-scattering layer masterbatch raw materials is as follows:

[0089] Recipe one:

[0090] The specific mass ratio of masterbatch raw materials is as follows:

[0091] Rutile titanium dioxide 426 parts

[0092] Stearic acid YA-Ⅱ-200 type 30 parts

[0093] PE wax 27 parts

[0094] LDPE 320 parts

[0095] LLDPE 197 parts

[0096] Recipe 2:

[0097] Rutile titanium dioxide 426 parts

[0098] Phthalocyanine blue 0.6 parts

[0099] Stearic acid YA-Ⅱ-200 type 30 parts

[0100] PE wax 26.4 parts

[0101] LDPE 367 parts

[0102] LLDPE 150 parts

[0103] Formula 3: The specific mass ratio of masterbatch raw materials is as follows:

[0104] Rutile titanium dioxide 427 parts

[0105] PE wax 20 parts

[0106] Oleamide 23 parts

[0107] LDPE 333 parts

[...

Embodiment 3

[0110] Embodiment 3 Masterbatch formulation of light-absorbing radiation layer

[0111] The light-absorbing radiation layer masterbatch is carbon black, silicon carbide micropowder, and LDPE (low-density polyethylene) masterbatch; the specific mass ratio of the light-absorbing radiation layer masterbatch raw materials is as follows:

[0112] Recipe one:

[0113] LDPE 48 parts

[0114] LLDPE 31 parts

[0115] 3 parts carbon black

[0116] Silicon carbide powder 11 parts

[0117] 2 parts of coupling agent

[0118] 1 part dispersant

[0119] 2 parts plasticizer

[0120] PE wax 3 parts

[0121] Recipe 2:

[0122] LDPE 46.5 parts

[0123] LLDPE 28 parts

[0124] PE wax 2 parts

[0125] Carbon black 2.5 parts

[0126] Silicon carbide powder 13 parts

[0127] 3 parts of coupling agent

[0128] dispersant 3 parts

[0129] 2 parts plasticizer

[0130] Recipe three:

[0131] LDPE 49 parts

[0132] LLDPE 27 parts

[0133] 3 parts carbon black

[0134] Silicon carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com