Frostless condensation heat regeneration type solution dehumidification aircraft ground air conditioning box

A solution dehumidification and air-conditioning box technology, applied in refrigerators, heating methods, air-conditioning systems, etc., can solve the problems of easy frosting and energy consumption of evaporators, and achieve the effects of convenient operation, stable output cooling capacity, and reduced heat consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

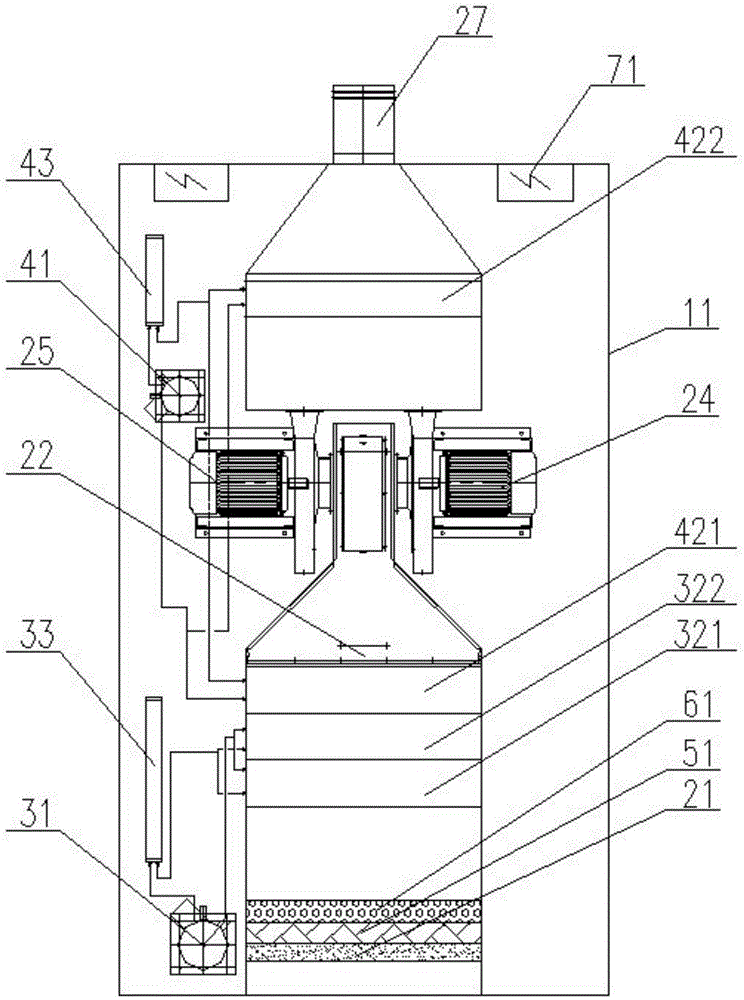

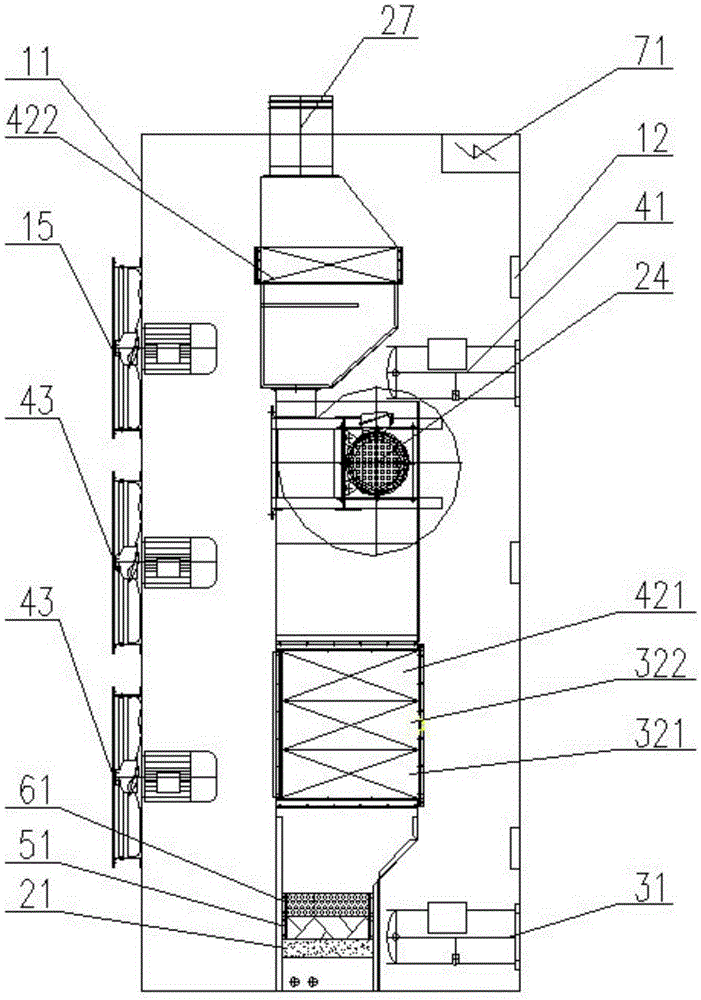

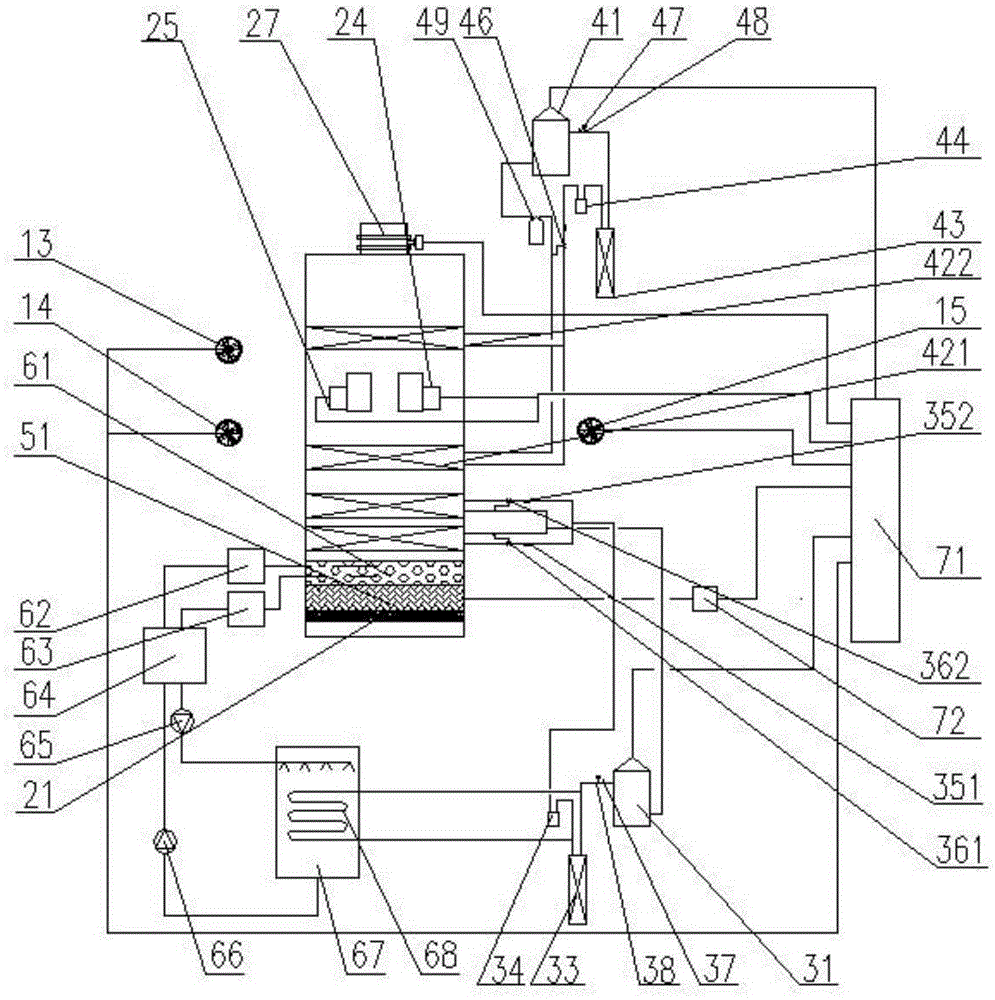

[0016] Specific implementation mode one: as figure 1 As shown, a frost-free condensation heat regeneration type solution dehumidification aircraft ground air conditioning box in this embodiment includes a frame 11, an air-conditioning air supply system, a solution dehumidification system 61, a refrigeration system, a heating system and an automatic control system; The system includes a first high-pressure blower 24, a second high-pressure blower 25, a filter 21, an air duct 22 and an air outlet 27; the solution dehumidification system 61 includes a concentrated solution tank 62, a dilute solution tank 63, a heat exchange box 64, a dilute solution pump 65, concentrated solution pump 66 and evaporative condensation regenerator 67; the refrigeration system includes a first compressor 31, a first front-stage evaporator 321, a first rear-stage evaporator 322, a first condenser 33, a first Liquid reservoir 34, pre-stage dry filter 351, post-stage dry filter 352, pre-stage expansion ...

specific Embodiment approach 2

[0017]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that: one side of the side wall of the frame 11 is provided with a ground-mounted mounting seat 12, and the other side of the side wall of the frame 11 is sequentially from top to bottom The third axial flow fan 15, the second axial flow fan 14 and the first axial flow fan 13 are provided; the third axial flow fan 15, the second axial flow fan 14 and the first axial flow fan 13 and the electrical control box 71 connected. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the dehumidifier 61 adopts the method of spraying tower cloth liquid, and the tower is filled with fillers. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com