High-precision automatic alignment ICT (In Circuit Tester)

An automatic alignment and testing machine technology, applied in the direction of electronic circuit testing, etc., can solve problems such as low production efficiency, inaccurate alignment, and low pass rate, and achieve the effects of reducing process difficulty, improving production efficiency, and simplifying employee operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

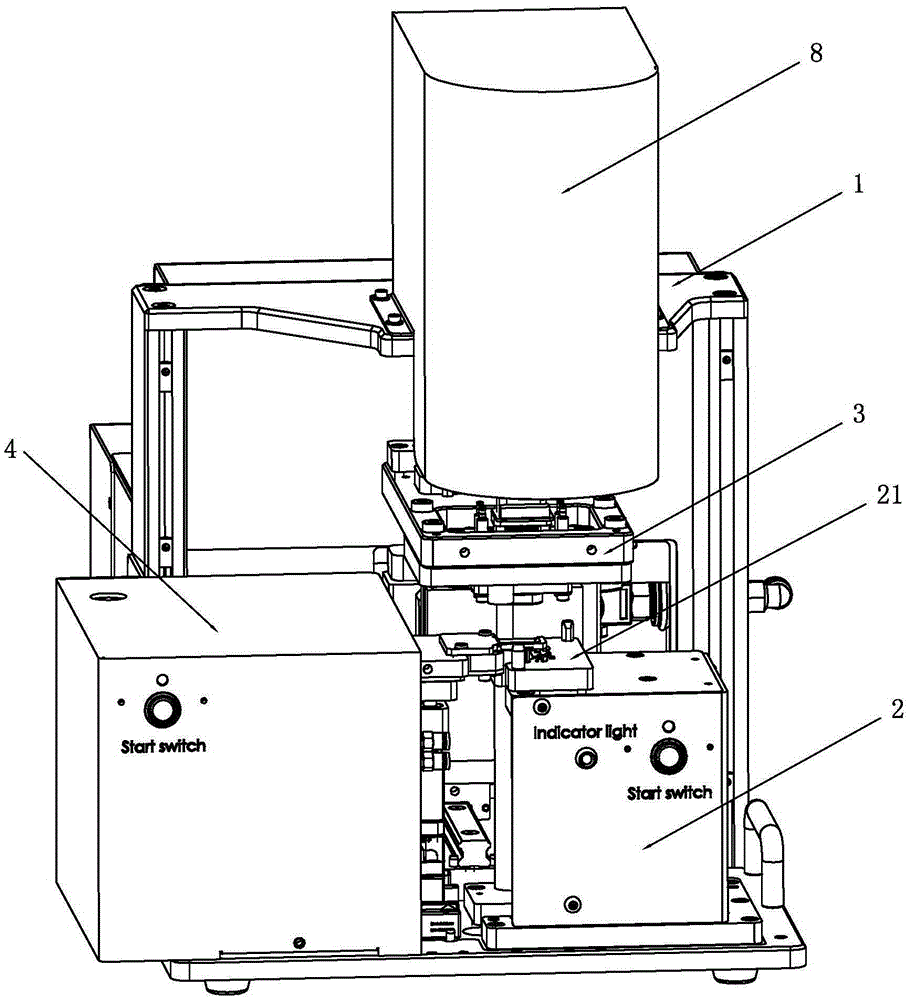

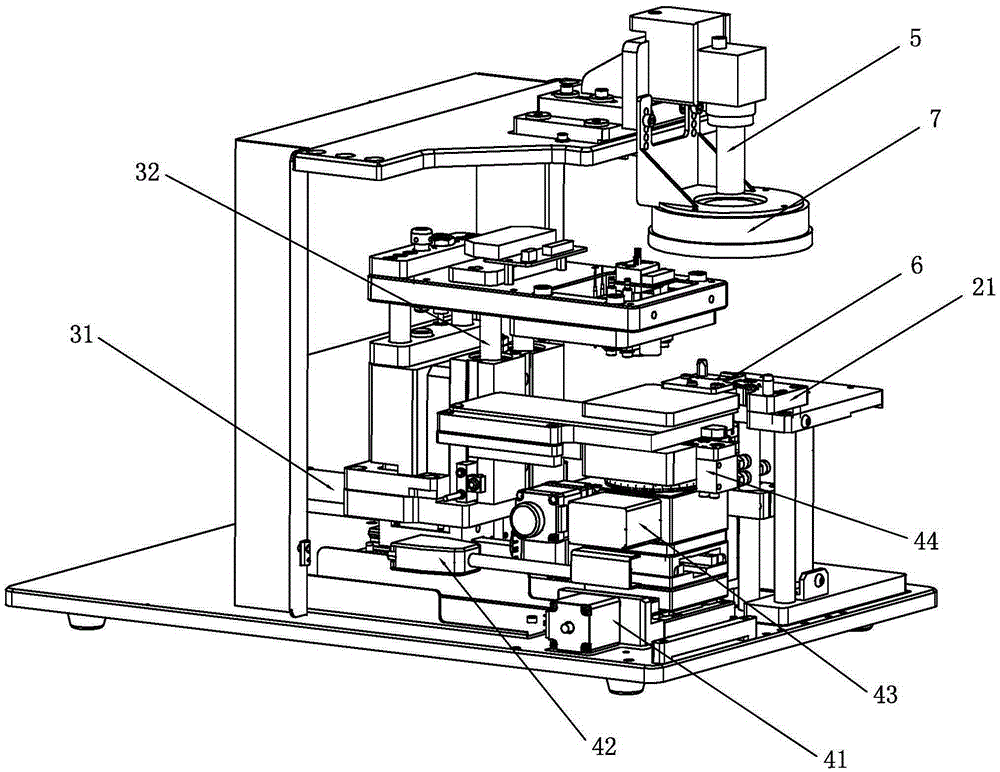

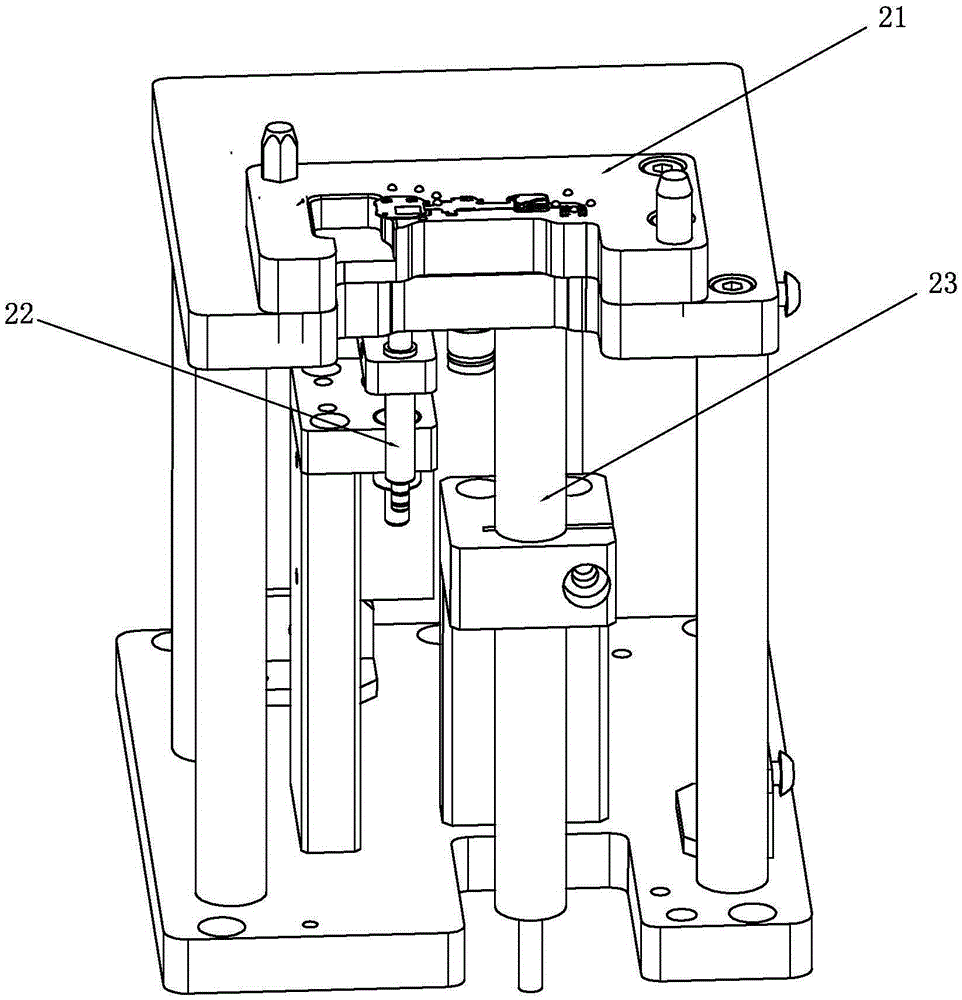

[0017] see figure 1 , a high-precision automatic alignment ICT testing machine of the present invention includes a frame 1, a lower mold assembly 2, an upper mold assembly 3 positioned at the rear side of the lower mold assembly 2, and a pair positioned at the left side of the lower mold assembly. The position adjustment platform 4, the lower mold assembly 2 includes a carrier board 21, and the FPC to be tested is placed on the carrier board 21.

[0018] see figure 2 The frame 1 is fixedly provided with a CCD camera 5, a light source 7 and a light source cover 8 at the position directly above the FPC. The light source 7 is positioned at the lower end of the CCD camera 5, and the light source cover 8 surrounds the CCD camera 5 and the light source 7 to ensure that the photographing effect is good. An adapter plate 6 is provided on the alignment adjustment platform 4, and the adapter plate 6 moves to the top of the FPC. The alignment adjustment platform 4 includes an X-axis ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com