Device and method for degrading alkaline organic waste water by iron-carbon micro-electrolysis

A technology of iron-carbon micro-electrolysis and organic wastewater, which is applied in chemical instruments and methods, processing process wastewater treatment, textile industry wastewater treatment, etc., and can solve problems such as increasing operating costs, increasing inorganic salts, and dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

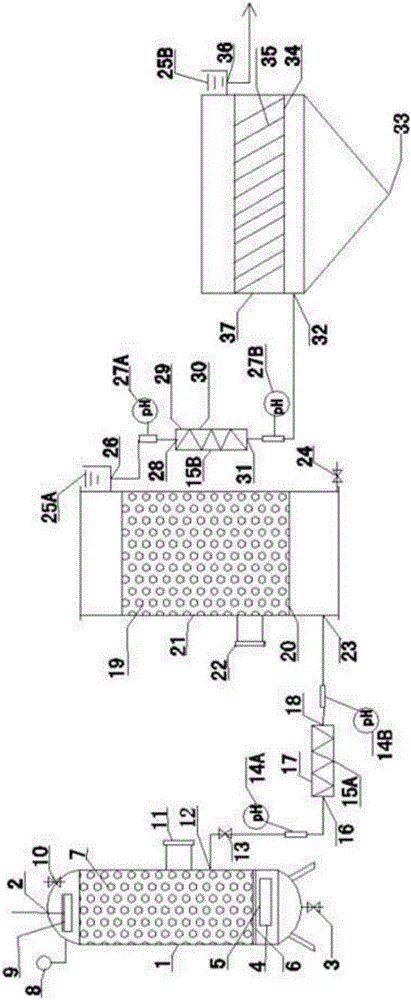

[0037] 80% of the raw water of the wiper cleaning solution of the banknote printing factory is filtered by an organic membrane for reuse, 20% of the concentrated water is alkaline pH=10, and the concentration of organic matter COD=13000mg / L. Sewage pressure fed into CO 2 After the pressure dissolving device 1 passes through the water distributor 9 and the CO dispersed through the air inlet 4 and the micro-nano aerator 5 2 Mixing and contacting in the filler 7, after the pressure reaches 0.3MPa, it is stable for 60-120min, and CO is dissolved 2 The sewage is exported to the iron-carbon micro-electrolysis reactor 21 through the water outlet 12, the pressure reducing valve 13, the pH online monitor 14A, 14B before and after the tubular reactor 15A, and acid is added to adjust the pH to 3-4. After the three-dimensional electrode formed by iron-carbon filler 19, the micro-nano CO 2 Under the action of air bubbles, a large number of hydroxyl radicals ( OH) are formed, which are ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com