Dynode film structure and electron multiplier based on dynode film structure

A technology of electron multiplier and thin-film structure, which is applied in the manufacture of circuits, electrical components, and cold cathodes. It can solve problems such as low process consistency, uneven sample surface, and insufficient performance of process materials, and achieve high secondary electron emission. coefficient, good attenuation characteristics, effects of stable chemical features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

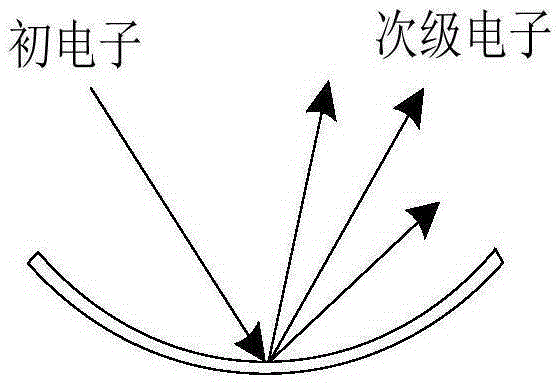

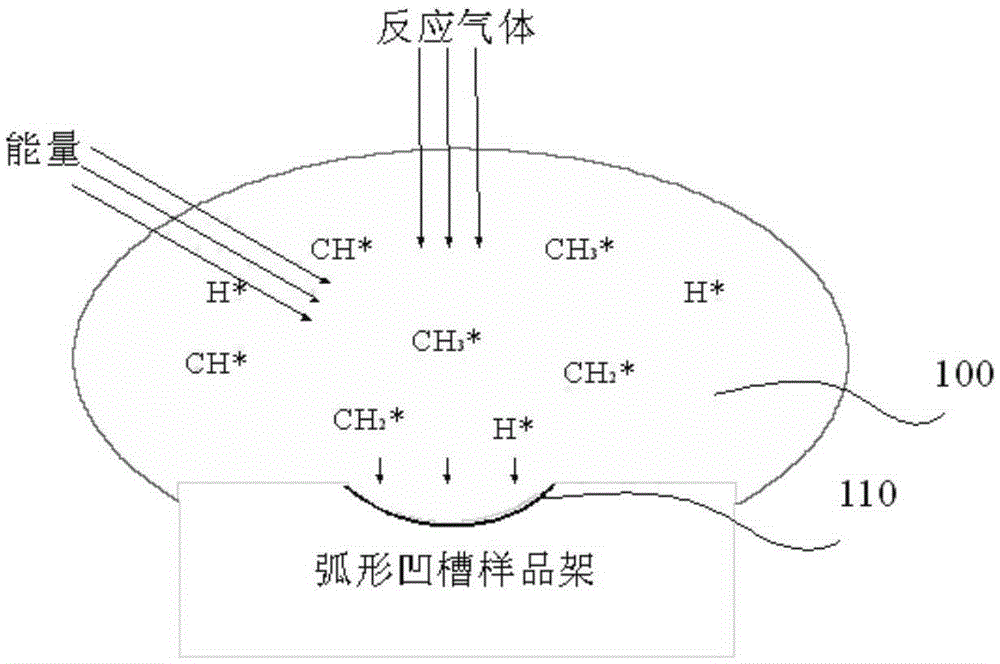

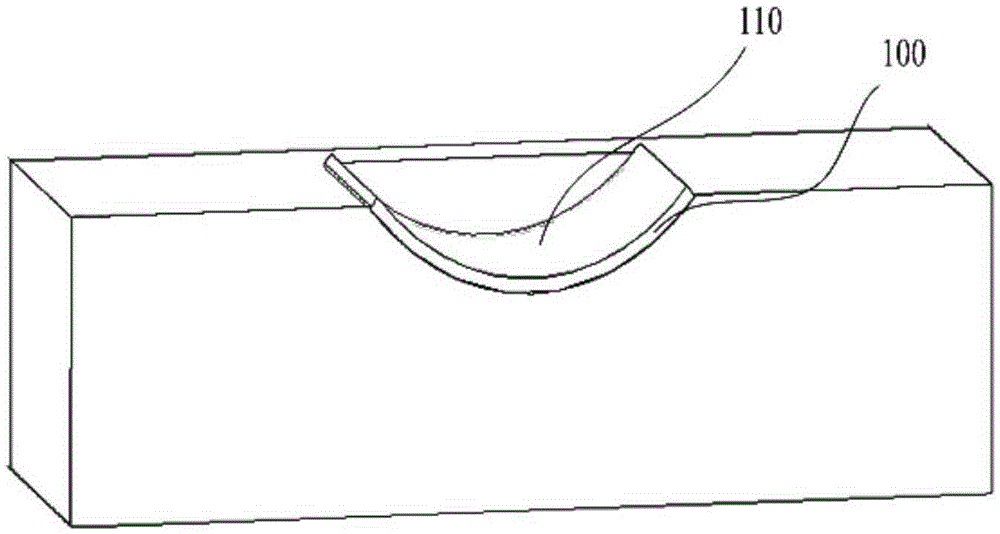

[0025] The dynode film structure of the present invention is a layer of diamond film 110 grown on the curved dynode sheet 100 by MPCVD.

[0026] The electron multiplier of the present invention includes a base frame body 130, a grid electrode 150 and an arc-shaped dynode piece 100; the base frame body 130 is a quarter cylindrical structure, wherein the base frame body 130 It includes a bottom plate, a first side plate and a second side plate, the first side plate and the second side plate are respectively connected to the two sides of the bottom plate, the arc-shaped dynode piece 100 is fixed on the upper part of the bottom plate, and the arc-shaped dynode The upper surface of the sheet 100 and the upper surface of the bottom plate are concave arc surfaces, and a layer of diamond film 110 is grown on the upper surface of the arc-shaped dynode sheet 100 by MPCVD, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com