Production and installation method of cement-based artificial stones for panels with heat preservation function

A cement-based, thermal insulation board technology, applied in the field of building decoration, can solve the problems of easy oxidation, fading, delamination, shelling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

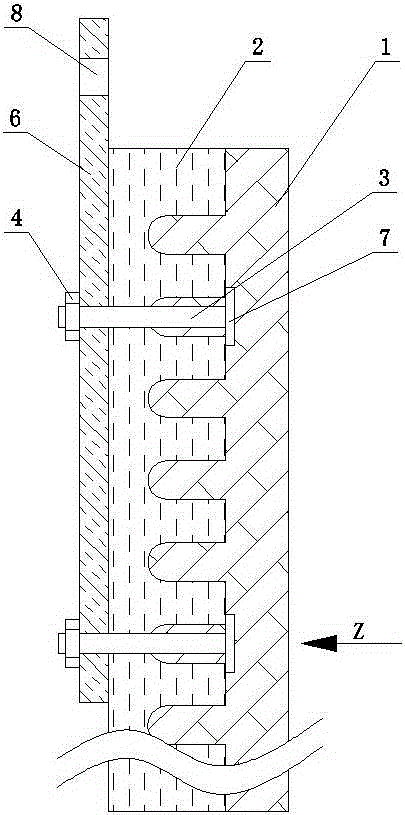

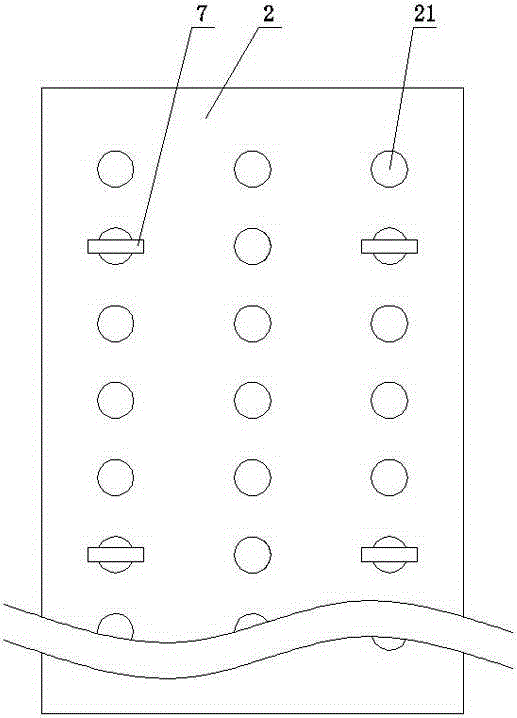

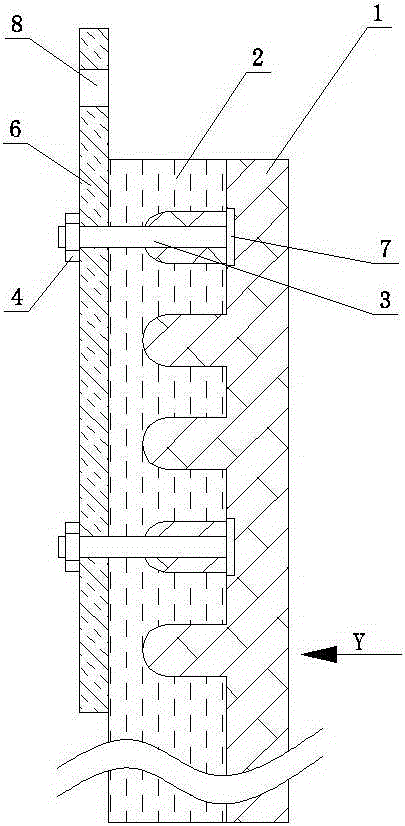

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] combine figure 1 , 3 , 5, the cement-based artificial flat stone with thermal insulation is formed by combining the cement-based artificial stone board 1 with the thermal insulation board 2, the bonding surface of the thermal insulation board 2 is provided with holes 21 or grooves 211, and the cement-based artificial stone board 1 combines The surface is provided with a protrusion matching the hole or groove. The cement-based artificial stone plate is pre-embedded with a stainless steel plate 7. The stainless steel plate 7 is connected with the connecting screw 3. The connecting screw 3 penetrates the protrusion and the insulation board 2, and its end is hung with the stainless steel. The bar 6 is connected, and the top of the hanging bar 6 is provided with a through hole 8.

[0027] The depth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com