A kind of solar glass anti-reflection anti-fouling paint and production method thereof

A technology of solar glass and anti-fouling coating, applied in the direction of coating, etc., can solve the problems of poor weather resistance of solar anti-reflection glass, easy alkaline hydrolysis, contradictory technical indicators of weather resistance and anti-reflection rate, etc., and achieve high weather resistance , not easy to accumulate, high anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

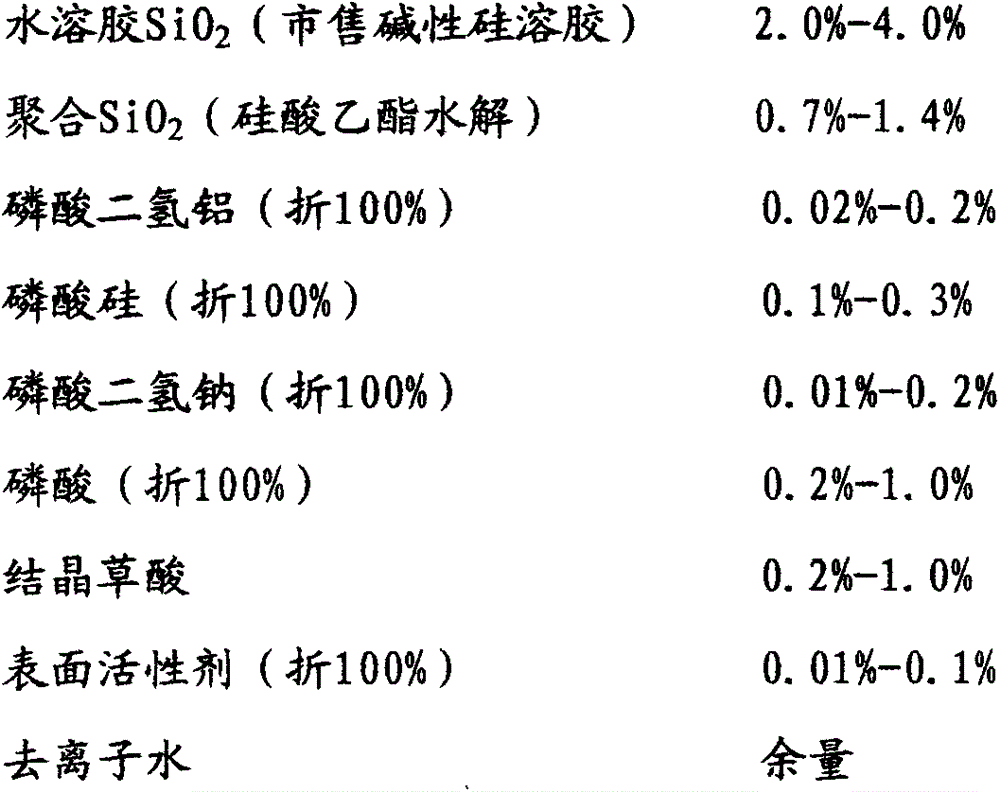

Method used

Image

Examples

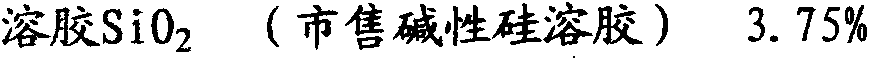

Embodiment 1

[0037] Add 800 g of deionized water to a 2000 mL reactor equipped with a mechanical stirrer, a thermometer, a dropping funnel and a condenser tube, add 150 g of alkaline silica sol with a mass percentage concentration of 25% under stirring, and use a mass percentage concentration of 20% % dilute phosphoric acid to adjust the silica hydrosol to PH9-10, filter to remove insoluble impurities, and obtain transparent silica hydrosol A; add 45g of ethyl silicate, and stir the reaction at 20-30°C for 4-8 hours to Ethyl silicate is completely dissolved, and aged at room temperature for 12 hours to form a slightly blue silica hydrosol B; then adjust the hydrosol to PH2-3 with a 20% mass percent concentration of phosphoric acid solution, and then heat it at 60-80°C Under vacuum distillation, remove about 10% solvent, obtain silicon dioxide hydrosol C; add mass percentage concentration and be 1.0g of lauric acid diethanolamide surfactant, form silicon dioxide hydrosol D; Add mass percenta...

Embodiment 2

[0042] Add 800 g of deionized water to a 2000 mL reactor equipped with a mechanical stirrer, a thermometer, a dropping funnel and a condenser tube, add 150 g of alkaline silica sol with a mass percentage concentration of 25% under stirring, and use a mass percentage concentration of 20% % dilute phosphoric acid to adjust the silica hydrosol to PH9-10, filter to remove insoluble impurities, and obtain transparent silica hydrosol A; add 45g of tetraethyl orthosilicate, stir and react at 20-30°C for 4-8 hours Until the ethyl silicate is completely dissolved, age at room temperature for 12 hours to form a slightly blue silica hydrosol B; then use a 20% mass percent concentration of dilute phosphoric acid solution to adjust the hydrosol to PH2-3, and then in 60-80 Remove about 10% of the solvent by vacuum distillation at °C to obtain silica hydrosol C; add 1.0 g of 10% lauric acid diethanolamide surfactant to form silica hydrosol D; add phosphoric acid with a concentration of 5% by ...

Embodiment 3

[0047] Add 800g of deionized water to a 2000mL reactor equipped with a mechanical stirrer, a thermometer, a dropping funnel, and a condenser tube, add 100g of 25% alkaline silica sol under stirring, and adjust with dilute phosphoric acid with a concentration of 20% by mass. Silica hydrosol to PH9-10, filter to remove insoluble impurities to obtain transparent silica hydrosol A; add 90g of ethyl silicate, stir and react at 20-30°C for 4-8 hours until the ethyl silicate is complete Dissolve and age at room temperature for 12 hours to form slightly blue silica hydrosol B; then adjust the hydrosol to PH2-3 with 20% dilute phosphoric acid solution, and then remove about 10% of the solvent by vacuum distillation at 60-80°C to obtain Silica hydrosol C; add 1.0 g of 10% lauric acid diethanolamide surfactant to form silica hydrosol D; add 5% aluminum dihydrogen phosphate hydrosol 40g , stirring and dissolving to form a silicon-aluminum composite hydrosol E; add 20 g of newly prepared s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com