Preparation method of sintering body with principal crystalline phase of cordierite by using coal gangue and nickel slag

A coal gangue and cordierite technology, applied in the field of material science, can solve the problem of coal gangue not being effectively used, and achieve the effect of reducing firing temperature and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The coal gangue is crushed and ball-milled by a crocodile crusher and a ball mill, and the nickel slag is ball-milled by a ball mill and passed through a 200-mesh square sieve to obtain coal gangue and nickel slag powder; Mix with 5g nickel slag into a sealed bag, and mix by hand for 15min.

[0017] Put the uniformly mixed dry powder into a stirring vessel, add 10ml of water and stir; after stirring evenly, put it into a cylindrical mold with a diameter of 25mm and a height of 30mm for molding, and then put it in a 45°C oven to dry to constant weight and demould.

[0018] Put the demolded cylindrical body into a high-temperature furnace at 1250°C for 15min, and finally obtain a volume shrinkage rate of 20.1% and an apparent density of 1960kg / m2. 3 , a sintered body with a compressive strength of 42 MPa and cordierite as the main crystal phase.

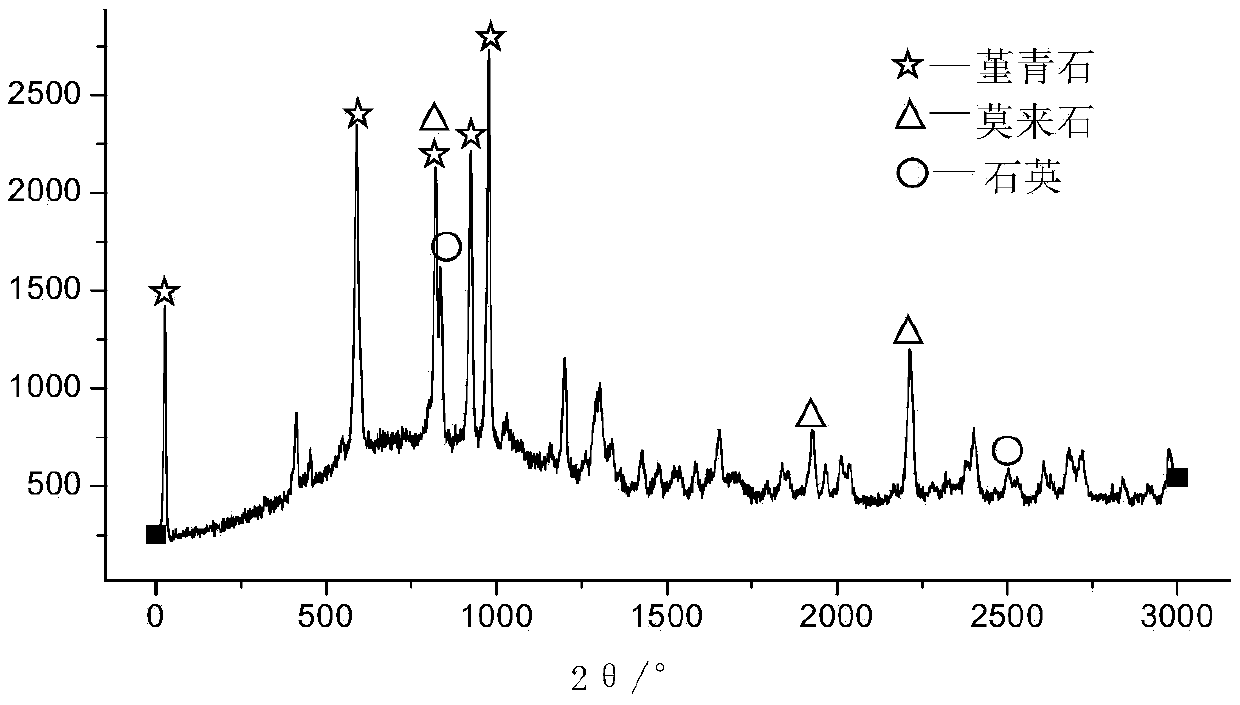

[0019] like figure 1 Shown: coal gangue: nickel slag = 80%: 20%, the sintered body XRD pattern of the sintered body at a fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com