La-Mg-Ni hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy and alloy technology, which is applied in the field of hydrogen storage materials, can solve the problems such as the difficulty of obtaining phases, and achieve the effects of easy mastery, fast phase transition kinetics, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

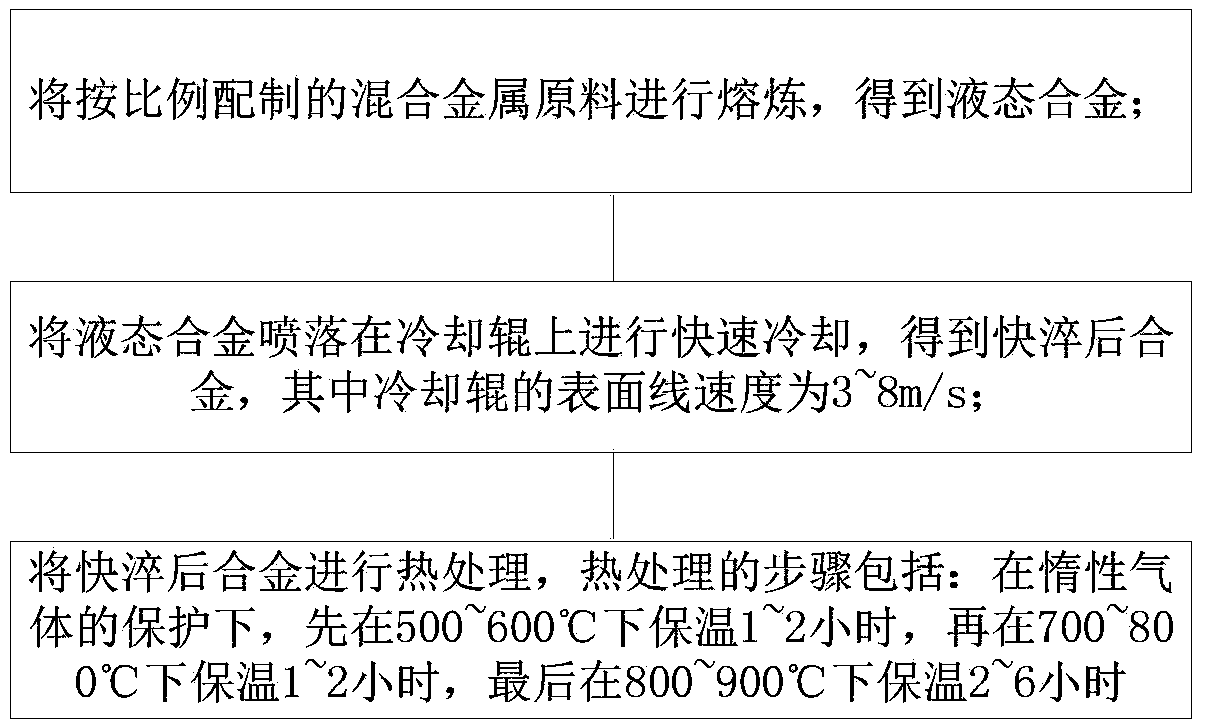

[0029] The inventors of the present invention provide a method for preparing a La-Mg-Ni hydrogen storage alloy. Such as figure 1 As shown, the preparation method includes the following steps: melting the mixed metal raw materials prepared in proportion to obtain a liquid alloy; spraying the liquid alloy on a cooling roll for rapid cooling to obtain a rapidly quenched alloy, wherein the surface line of the cooling roll The speed is 3-8m / s; heat treatment is carried out on the rapidly quenched alloy. The steps of heat treatment include: under the protection of inert gas, first keep warm at 500-600°C for 1-2 hours, and then keep warm at 700-800°C for 1 hour ~ 2 hours, and finally keep warm at 800 ~ 900 ℃ for 2 ~ 6 hours.

[0030] Above-mentioned preparation method adopts medium and low speed rapid quenching method to AB 5 The content of the type phase is suppressed in an appropriate range, and at the same time, a rapidly quenched alloy with uniform composition and structure is ...

Embodiment 1

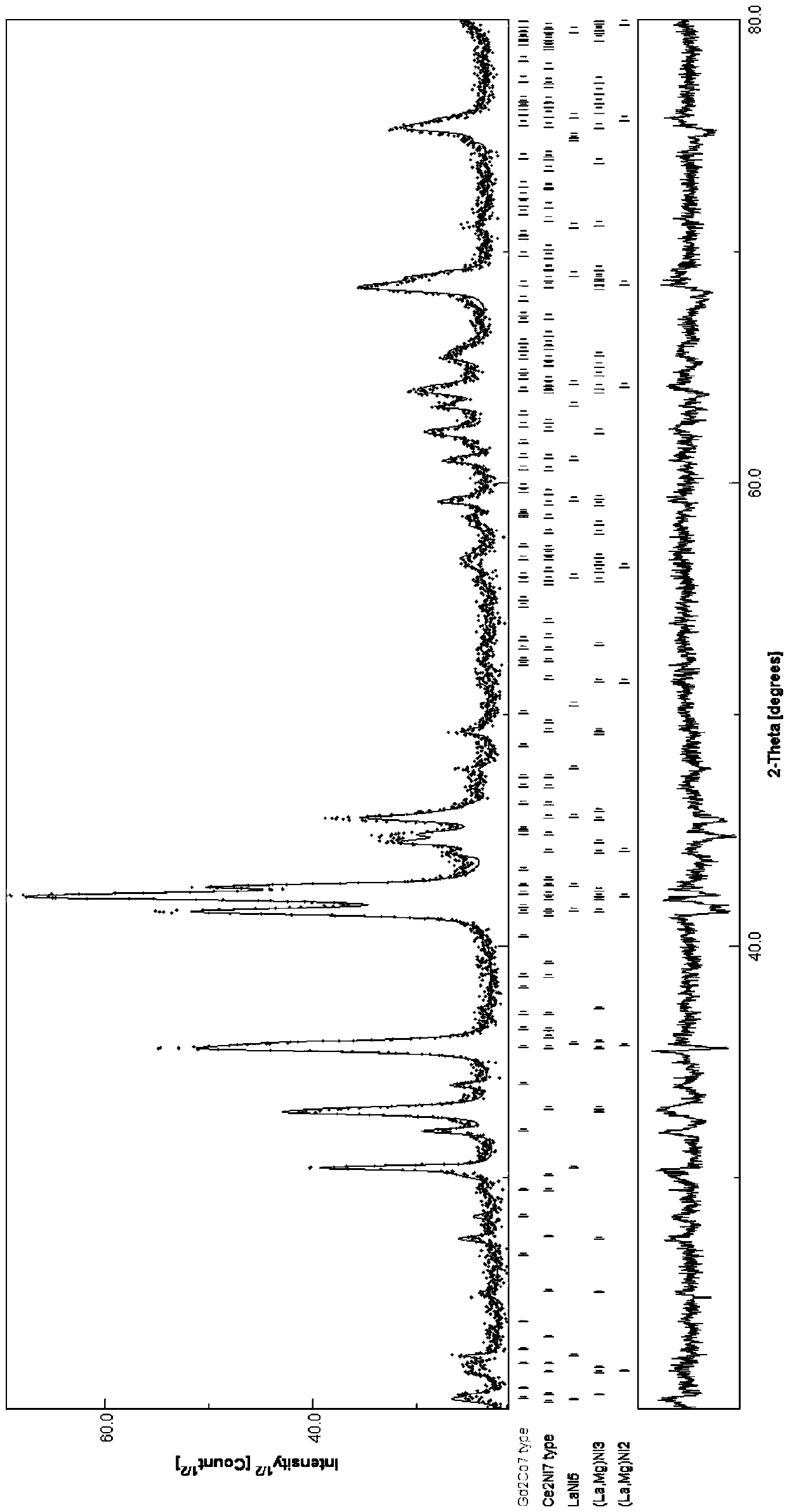

[0050] The chemical formula of the La-Mg-Ni hydrogen storage alloy provided in this embodiment is La 1.8 Mg 0.2 Ni 7 , and the XRD analysis shows that the La-Mg-Ni hydrogen storage alloy is only composed of a single A 2 B 7 Phase composition. Its preparation method comprises the following steps:

[0051] (1) The raw materials are proportioned to obtain mixed metal raw materials; the vacuum induction melting furnace is evacuated to 1×10 -4 Below Pa, fill it with argon to normal pressure, then evacuate again to 1×10 -4 Below Pa, it is filled with 0.01MPa high-purity helium for protection; the mixed metal raw material is melted at a temperature of 1573K-1873K, and kept for 1 minute to obtain a liquid alloy.

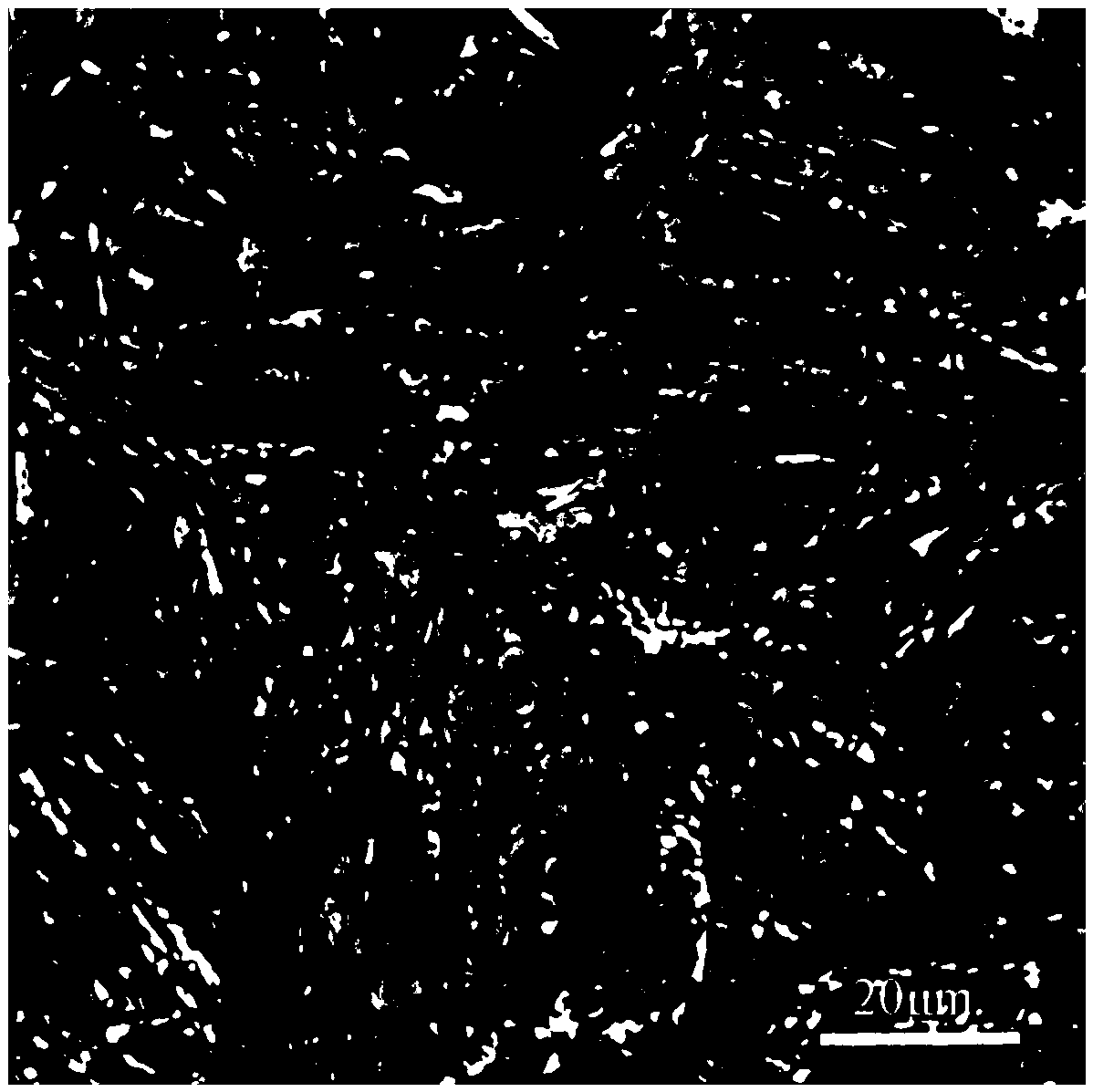

[0052] (2) Spray the liquid alloy on the water-cooled copper roll for rapid cooling. The surface linear velocity of the copper roll is 5m / s to obtain a rapidly quenched alloy with a thickness of 70 μm; XRD analysis shows that the crystal of the obtained rapidly quenche...

Embodiment 2

[0055] The chemical formula of the La-Mg-Ni hydrogen storage alloy provided in this embodiment is La 1.5 Mg 0.5 Ni 7 , and the XRD analysis shows that the La-Mg-Ni hydrogen storage alloy is only composed of a single A 2 B 7 Phase composition. Its preparation method comprises the following steps:

[0056] (1) The raw materials are proportioned to obtain mixed metal raw materials; the vacuum induction melting furnace is evacuated to 1×10 -4 Below Pa, fill it with argon to normal pressure, then evacuate again to 1×10 -4 Below Pa, it is filled with 0.1MPa high-purity helium for protection; the mixed metal raw material is melted at a temperature of 1573K-1873K, and kept for 1 minute to obtain a liquid alloy.

[0057](2) Spray the liquid alloy on the water-cooled copper roll for rapid cooling. The surface linear velocity of the copper roll is 5m / s to obtain a rapidly quenched alloy with a thickness of 70 μm; XRD analysis shows that the crystal of the obtained rapidly quenched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com