High ductility cement base strain transducer

A strain sensor, cement-based technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of small tensile strain range and difficulty in meeting engineering needs, etc., achieve large range, simple external equipment, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

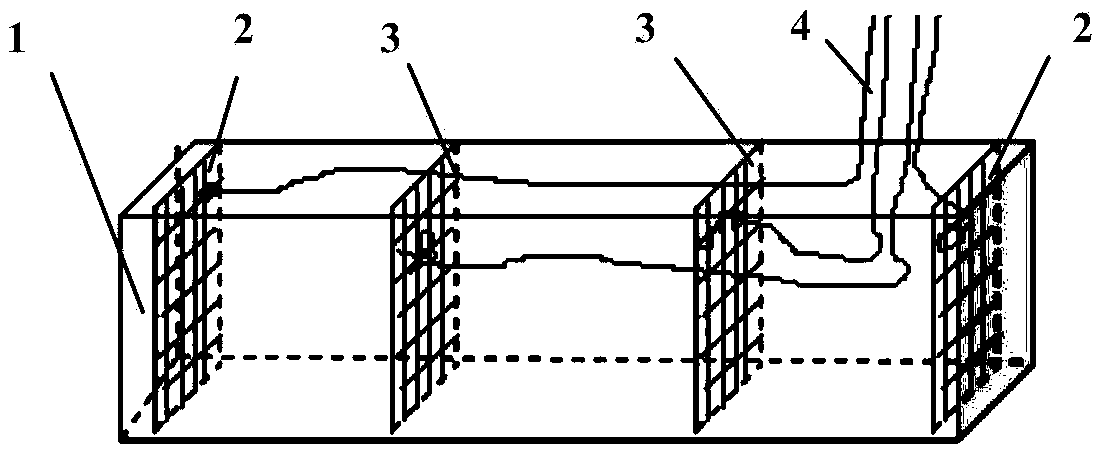

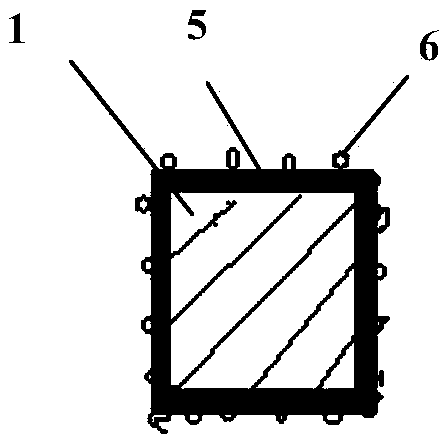

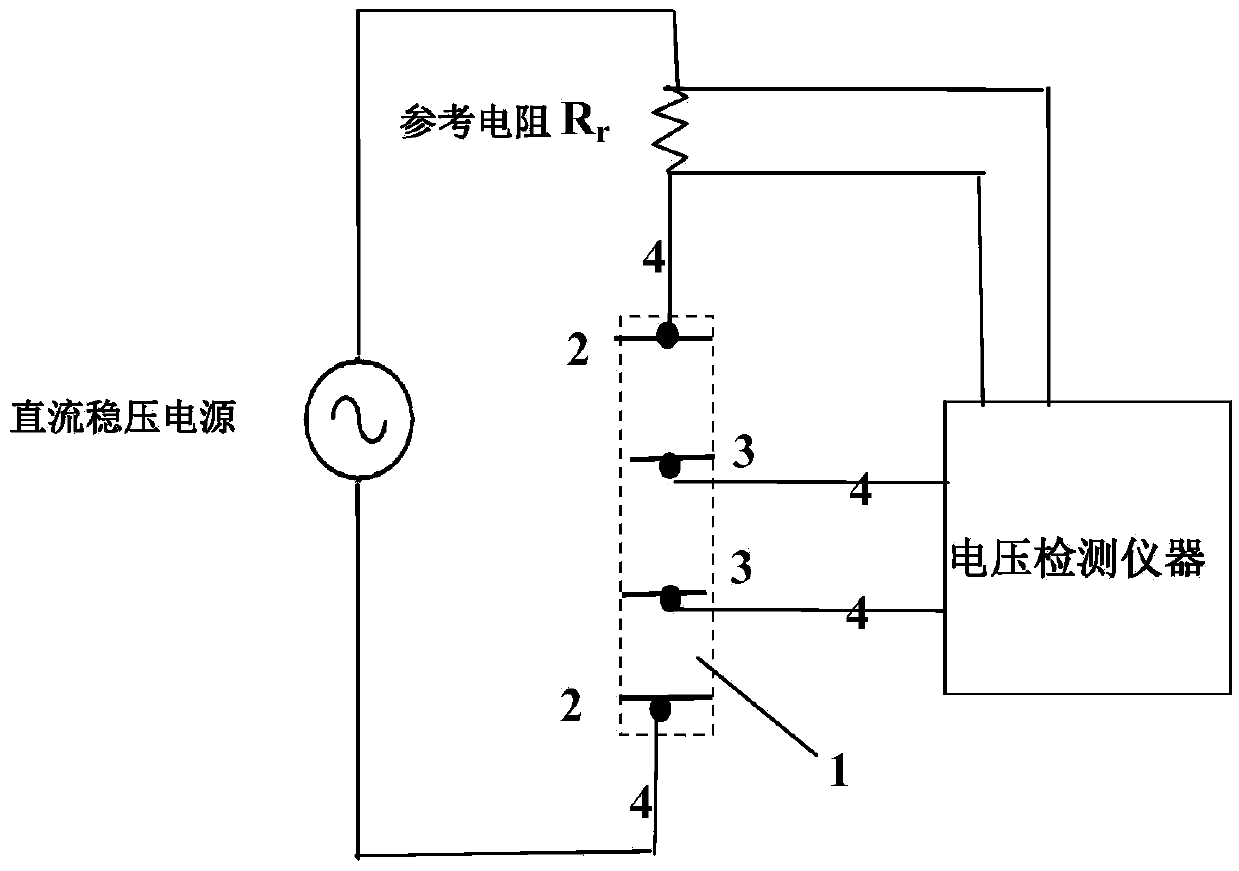

Method used

Image

Examples

specific Embodiment 1

[0053] The mass ratio of selected raw materials is: cement: fly ash: sand: water: polyvinyl alcohol fiber: GnPs: polycarboxylate water reducer: viscosity modifier = 1: 2.0: 1.35: 0.93: 0.067: 0.034: 0.033: 0.00076 . The selected GnPs (produced by XG Sciences Company in the United States) is in the form of flakes, with a particle size (D50) of 5 μm, a sheet thickness of 6-8nm, and a specific surface area of 120-150m 2 / g. GnPs have a conductivity of 10 7 S / m (parallel sheet direction) and 10 2 S / m (thickness direction). The polyvinyl alcohol fiber is produced by Anhui Wanwei High-tech Materials Co., Ltd. The fiber diameter is 35 μm, the length is 12 mm, the elastic modulus is 39.4 GPa, and the tensile strength is 1092 MPa. Ordinary Portland cement (brand P.O42.5) produced by Hubei Huaxin Cement Co., Ltd. and Class I fly ash from Wuhan Yangluo Power Plant were used. The polycarboxylate superplasticizer is ADVA152, produced by American Grace China Co., Ltd. The viscosity ...

specific Embodiment 2

[0057] The material ratio and material parameters are the same as in Example 1, and a HDCSS with a cross-sectional size of 40mm×40mm and a height of 160mm is made, and the compressive strain and ΔR / R 0 Relationship. When compressing, place the HDCSS along the height direction, level the upper and lower surfaces of the HDCSS with superhard quick-drying gypsum, and fix the precision LVDT displacement gauge in the area where the two measuring electrodes are located to measure the compressive strain. The obtained compressive strain and ΔR / R 0 relationship curve as Image 6 As shown, the specific expression of the piecewise function in formula (3) at this time is:

[0058]

[0059] When detecting compressive strain, R x Decreases with increasing absolute value of strain, ΔR / R 0 is a negative number, that is, compressive strain and ΔR / R 0 Both are negative. The range of HDCSS measuring compressive strain is -0.0023~0 (ie -0.23%~0).

[0060] Combining formulas (5) and (6) i...

specific Embodiment 3

[0067] Change the dosage of GnPs, and the ratio of materials is shown in Table 1. Material parameters, preparation method and test method are the same as in Example 1. The volume dosages of GnPs corresponding to A1-A6 in Table 1 are 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, and 1.2%, respectively. Wherein, A3 is the proportioning that embodiment 1 adopts. When the volume dosage of GnPs is greater than 1.2%, it is difficult for GnPs to disperse uniformly. Table 2 shows the measured sensitivity of HDCSS prepared with different dosages of GnPs, and piecewise functions similar to formulas (5) and (6) can also be obtained. The sensing range of tensile strain of various HDCSS is above 3.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com