High-power chip whole-film fixed resistor and production method thereof

A technology of fixed resistance and thin film resistance, used in thin film resistors, resistors, resistance manufacturing and other directions, can solve the problems of poor stability, low power, low precision, etc., and achieve the effects of good stability, reduced volume and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

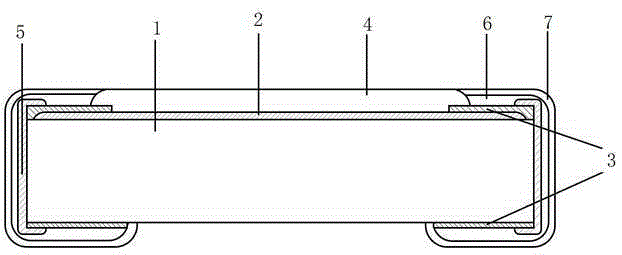

[0025] figure 1 A schematic diagram of the basic structure of a high-power chip-type full-film fixed resistor is given. It can be seen from the accompanying drawings that the high-power chip-type full-film fixed resistor in the present invention includes an aluminum nitride substrate 1, an aluminum nitride substrate formed on the substrate The thin film resistance film layer 2 on the upper surface, the front and back electrode film layer 3 formed on the substrate, the secondary protective layer 4 located on the thin film resistance film layer, the thin film terminal electrode layer 5 sputtered on the end of the substrate, and the front and back electrode layer The nickel barrier layer 6 on the surface of the film layer and the film terminal electrode layer, and the tin-lead solderable layer 7 on the nickel barrier layer. A high-power chip-type full-fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com