Resistor material, sputtering target for forming resistive thin film, resistive thin film, thin film resistor and method of producing the same

A technology of resistive film and resistive body, applied in the direction of coating resistive materials, conductive materials dispersed in non-conductive inorganic materials, resistors, etc., can solve the problem of low resistivity, achieve high temperature stability, excellent resistance temperature characteristics, manufacturing cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

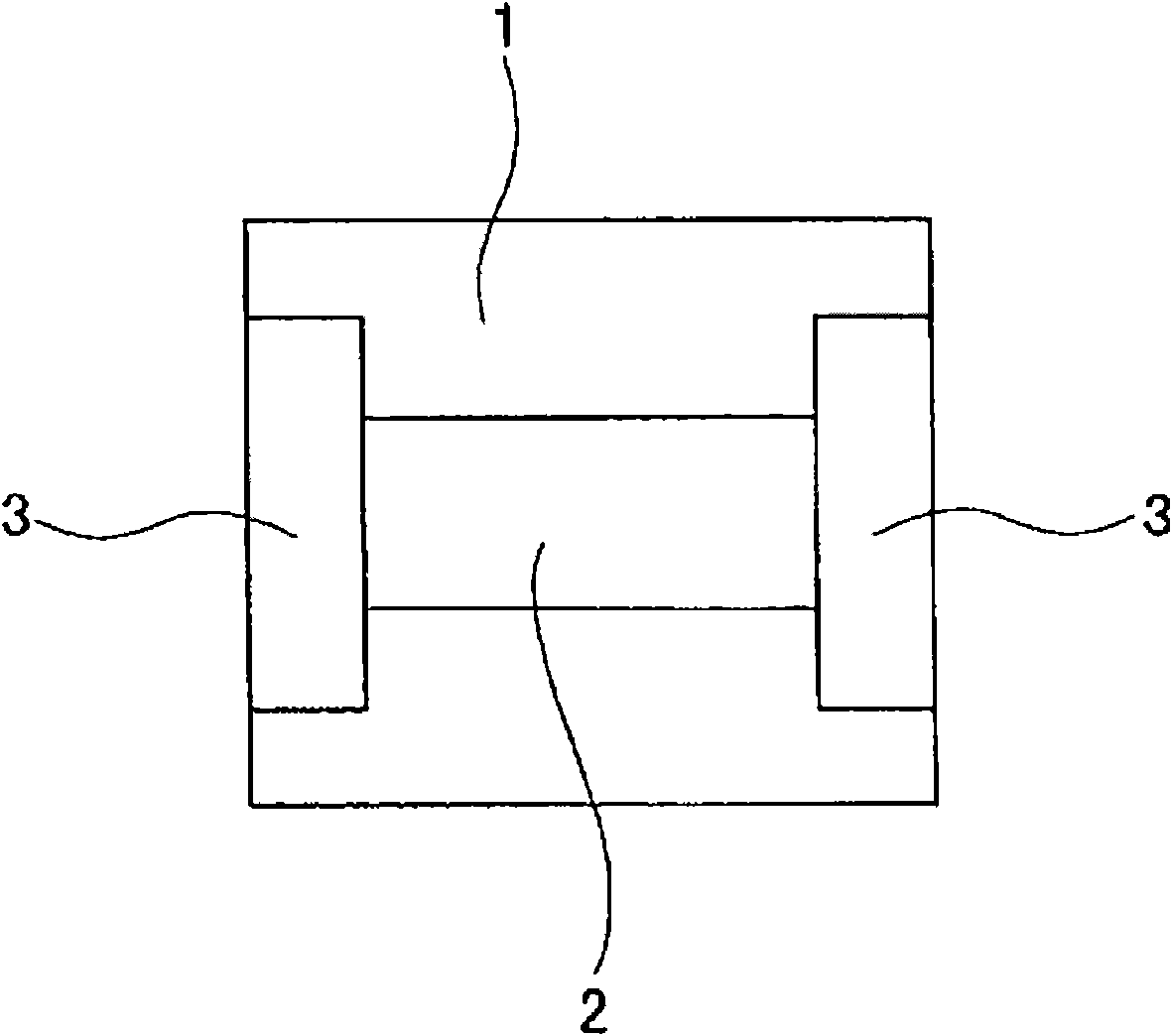

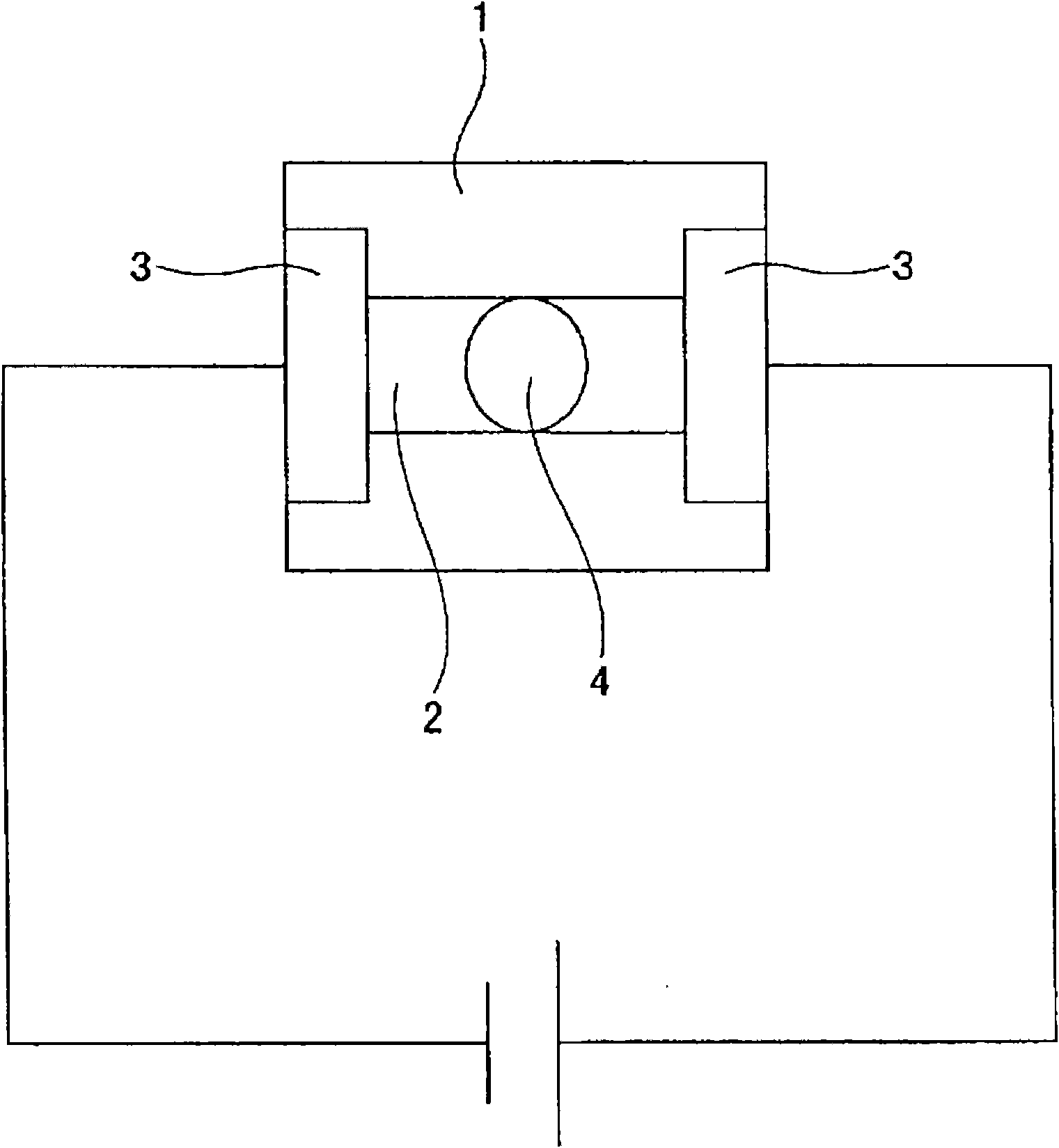

Image

Examples

Embodiment 1

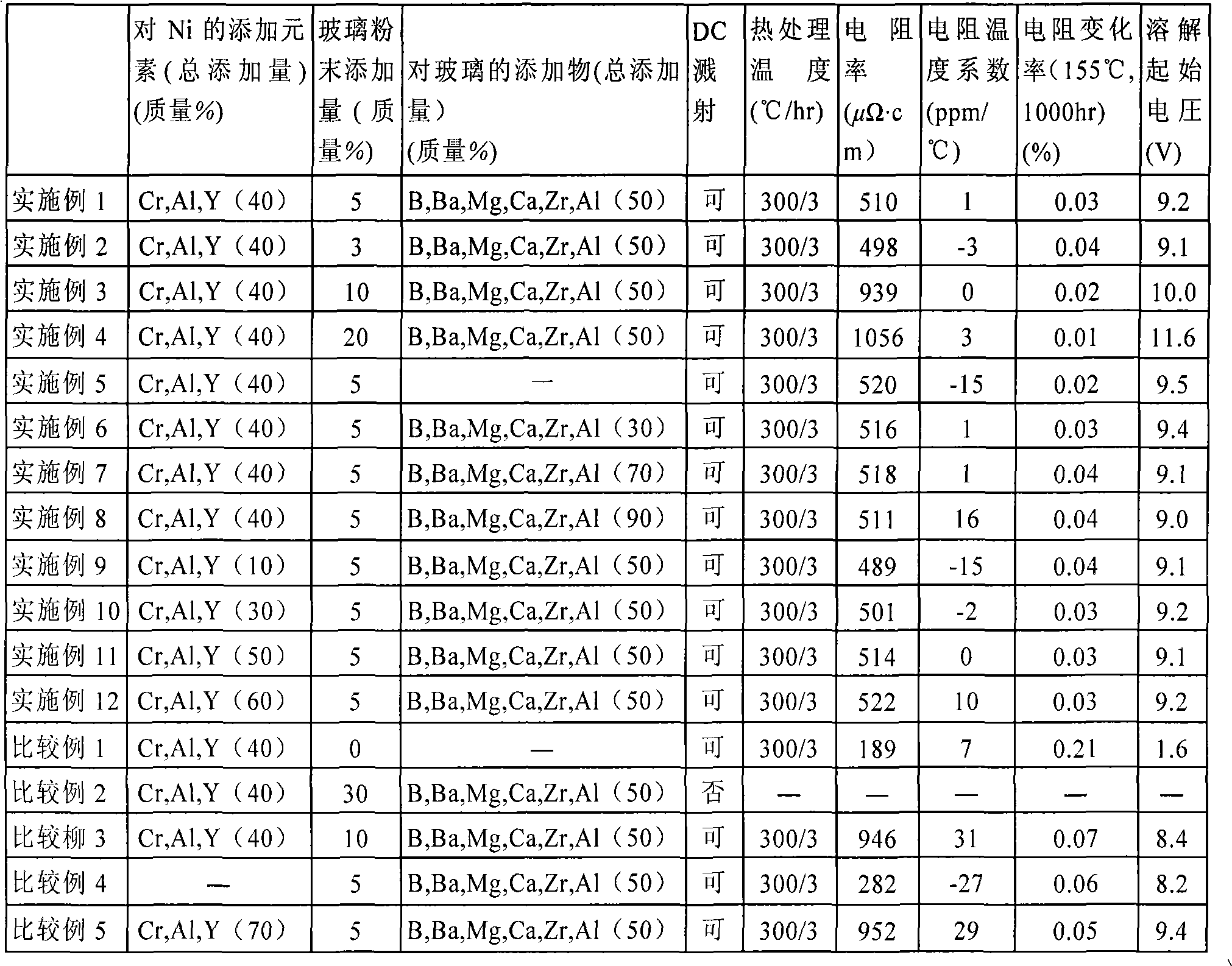

[0056] As Ni alloy powder, a Ni alloy powder having an average particle diameter of 100 μm was prepared by adding Cr, Al, and Y in a total amount of 40% by mass (Cr:Al:Y=29.5:10.0:0.5 (mass ratio)). On the other hand, as a silicate-based glass powder, B, Mg, Ca, Ba, Al, and Zr were added in a total amount of 50% by mass (B:Mg:Ca:Ba:Zr:Al=2:5:18 : 18:5:2 (mass ratio)) SiO with an average particle size of 10 μm 2 powder.

[0057] These two kinds of powders were mixed so that the addition amount of the silicate-type glass powder was 5 mass %, and it was made into the raw material powder.

[0058] This raw material powder was put into a carbonaceous mold of a desired shape, and hot-pressed using an atmospheric hot-press furnace (AHP) manufactured by Hiroshiki Co., Ltd. (Hirashiki Co., Ltd.). In an inert gas environment where Ar flows at 2L / min, the so-called 200kg / cm 2 Under the conditions of pressure, calcination temperature of 1100° C., and calcination time of 3 hours, the mo...

Embodiment 2

[0071] Except having made the addition amount of the silicate-type glass powder into 3 mass %, it carried out similarly to Example 1, obtained the thin-film resistor, and examined the characteristic.

Embodiment 3

[0073] Except having made the addition amount of the silicate-type glass powder into 10 mass %, it carried out similarly to Example 1, obtained the thin-film resistor, and examined the characteristic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com