Etching method of double magnetic tunnel junctions

A technology of magnetic tunnel junction and magnetic tunnel, which is applied in the fields of magnetic field controlled resistors, manufacturing/processing of electromagnetic devices, static memory, etc., can solve problems such as short-circuit MTJ stack, failure, and inability to solve DMTJ short-circuit failure, so as to avoid possible The effect of short circuit and large application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

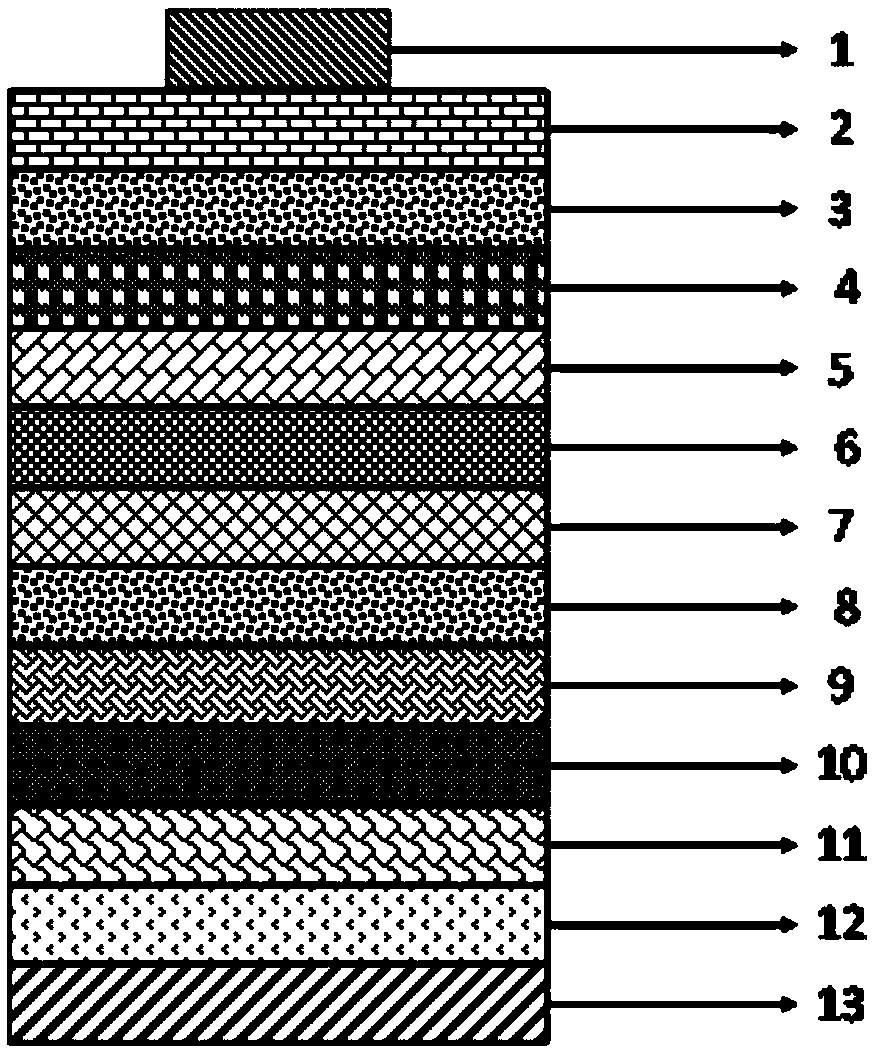

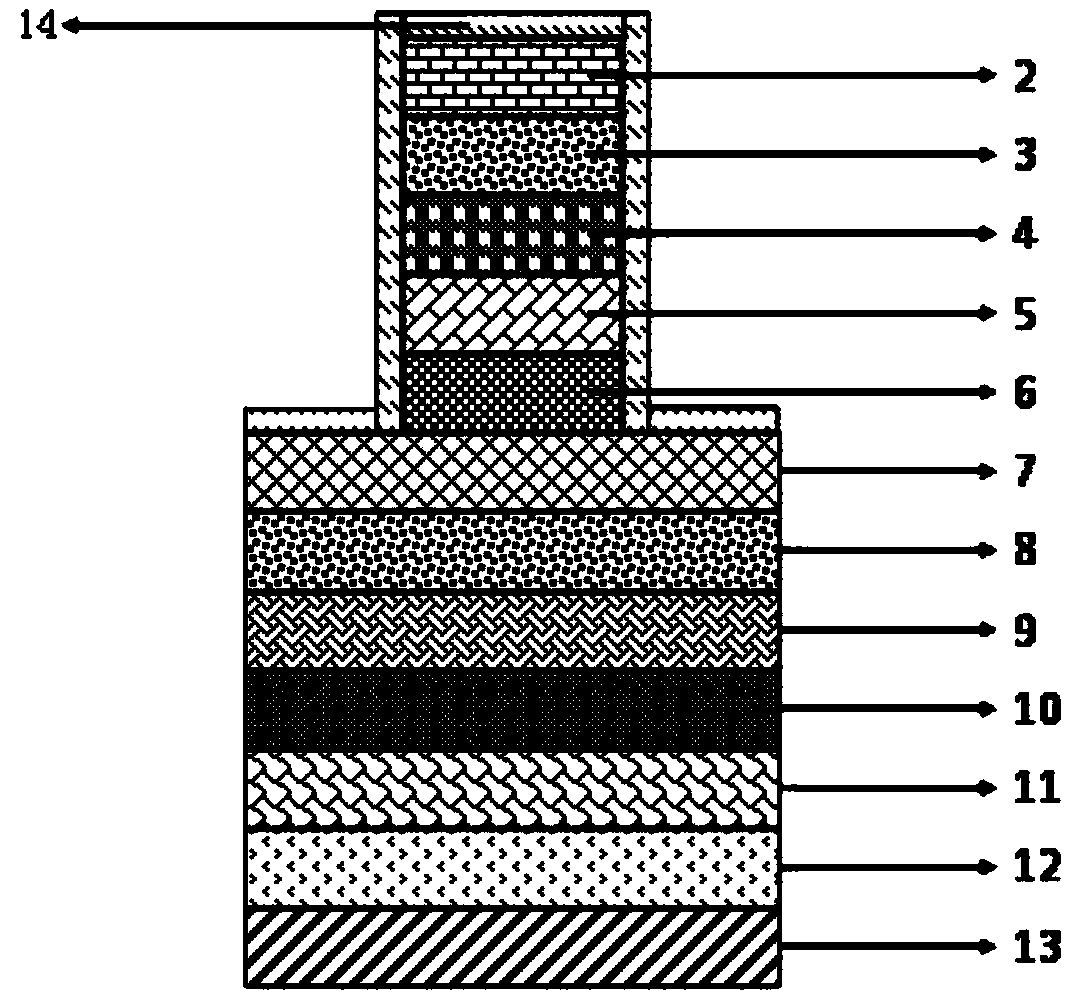

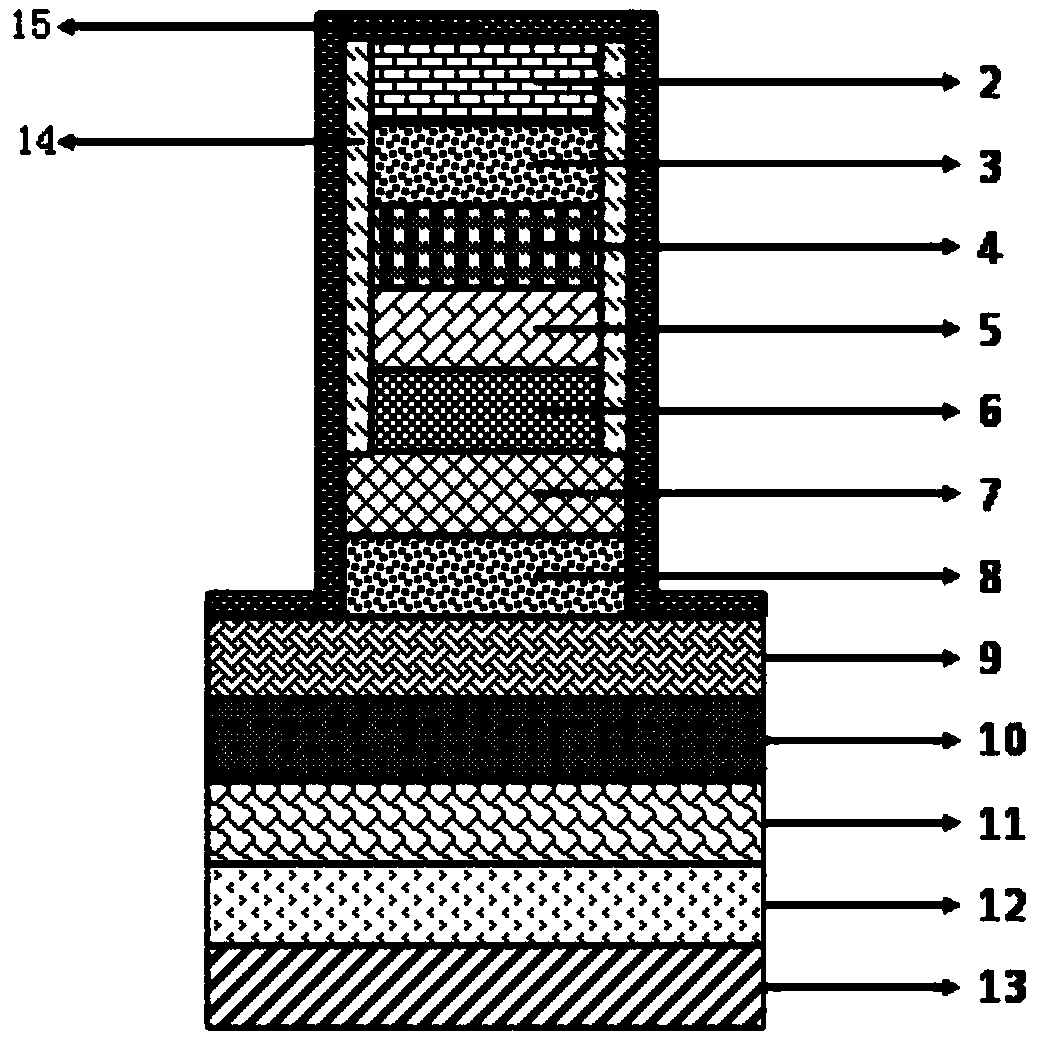

[0028] Embodiment 1: as figure 1 As shown, a photoresist template 1 with a certain shape is prepared in the selected area, the bottom electrode 12, the second antiferromagnetic layer 11, the second pinning layer 10, the second tunneling layer 9, the free layer 8, the first The tunneling layer 7 , the first pinning layer 6 , the first antiferromagnetic layer 5 , the top electrode 4 , the hard template buffer layer 3 and the hard template layer 2 are sequentially deposited on the 13 layers that have been prepared for the front-end process. In this embodiment, in order to simplify the etching process, the hard template buffer layer 3 can be etched under the same etching conditions as the top electrode 4, and the materials for the hard template buffer layer 3 are preferably silicon nitride, silicon carbide and its substitutes. Traditional silicon dioxide, silicon nitride, tantalum nitride and their substitutes are used to prepare the hard template layer 2 . Although figure 1 On...

Embodiment 2

[0032] Embodiment 2: A rectangular photoresist template 1 is prepared in the selected area, the bottom electrode, the second antiferromagnetic layer, the second pinning layer, the second tunneling layer, the free layer, the first tunneling layer, the second A pinning layer, a first antiferromagnetic layer, a top electrode, a hard template buffer layer and a hard template layer are sequentially deposited on the prepared front-end process layer. In this embodiment, in order to simplify the etching process, the hard template buffer layer can be etched under the same etching conditions as the top electrode, and the material of the hard template buffer layer is preferably silicon carbide. Tantalum nitride is used to prepare the hard template layer.

[0033] After the photoresist template layer is removed, the hard template layer replicating the shape of the photoresist template layer is used as a mask to continue etching. When the etching reaches the first tunneling layer, the etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com