Laser output power optimization method based on variable-transmittance endoscope

A technology of output power and optimization method, applied in lasers, laser parts, phonon exciters, etc., can solve the problem that the laser cannot be optimized on-line output power, and achieve the effect of avoiding the increase of development cost, convenient operation and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

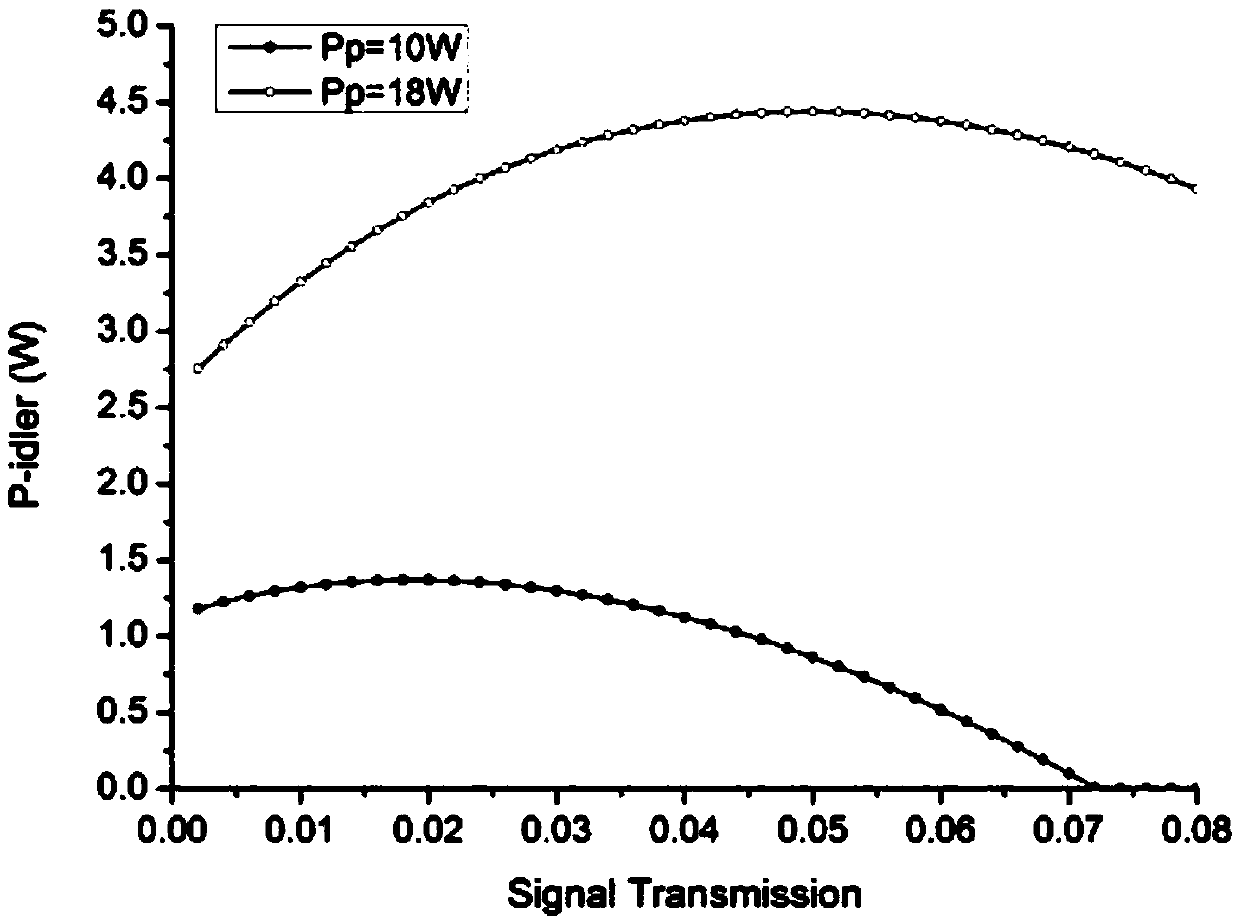

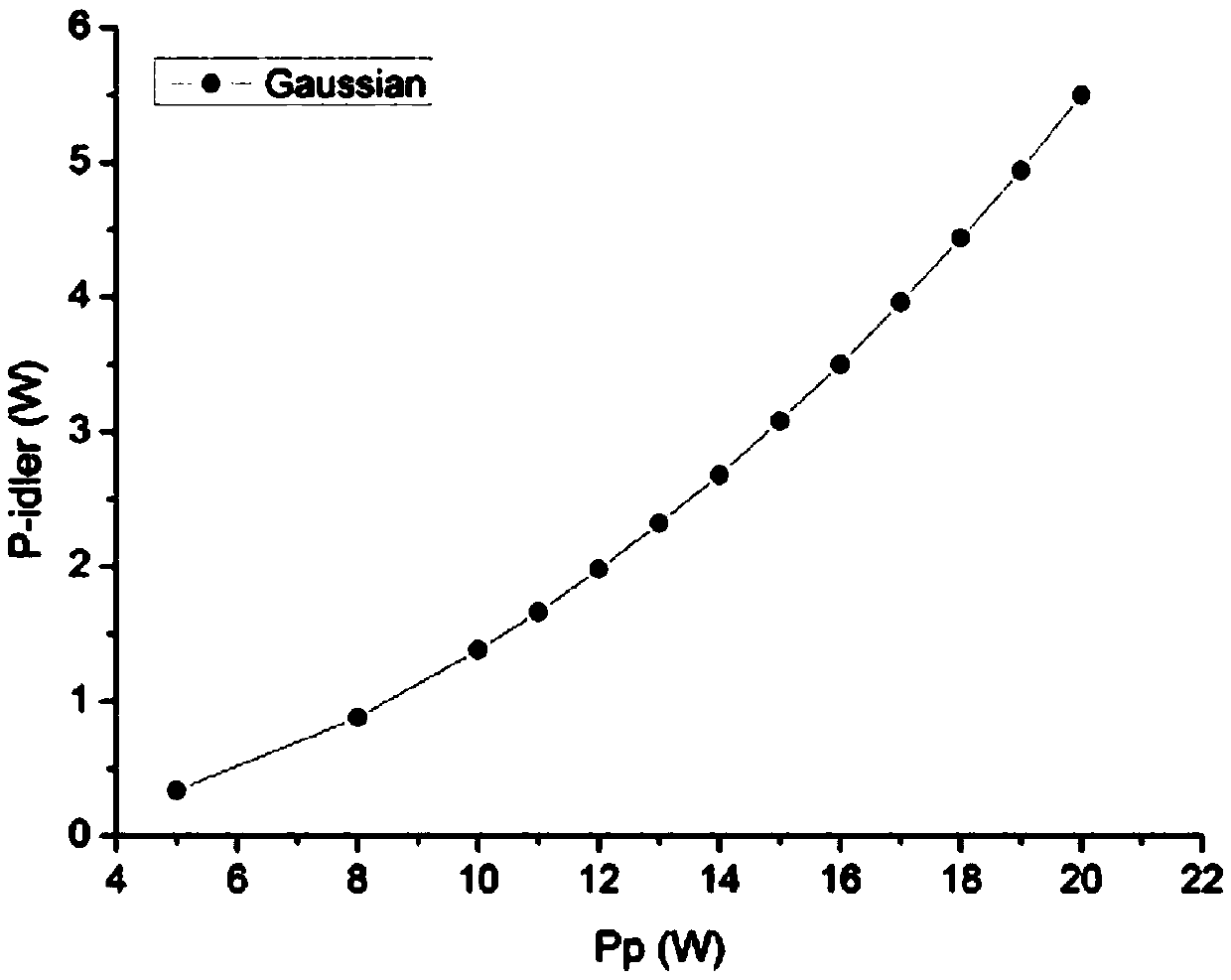

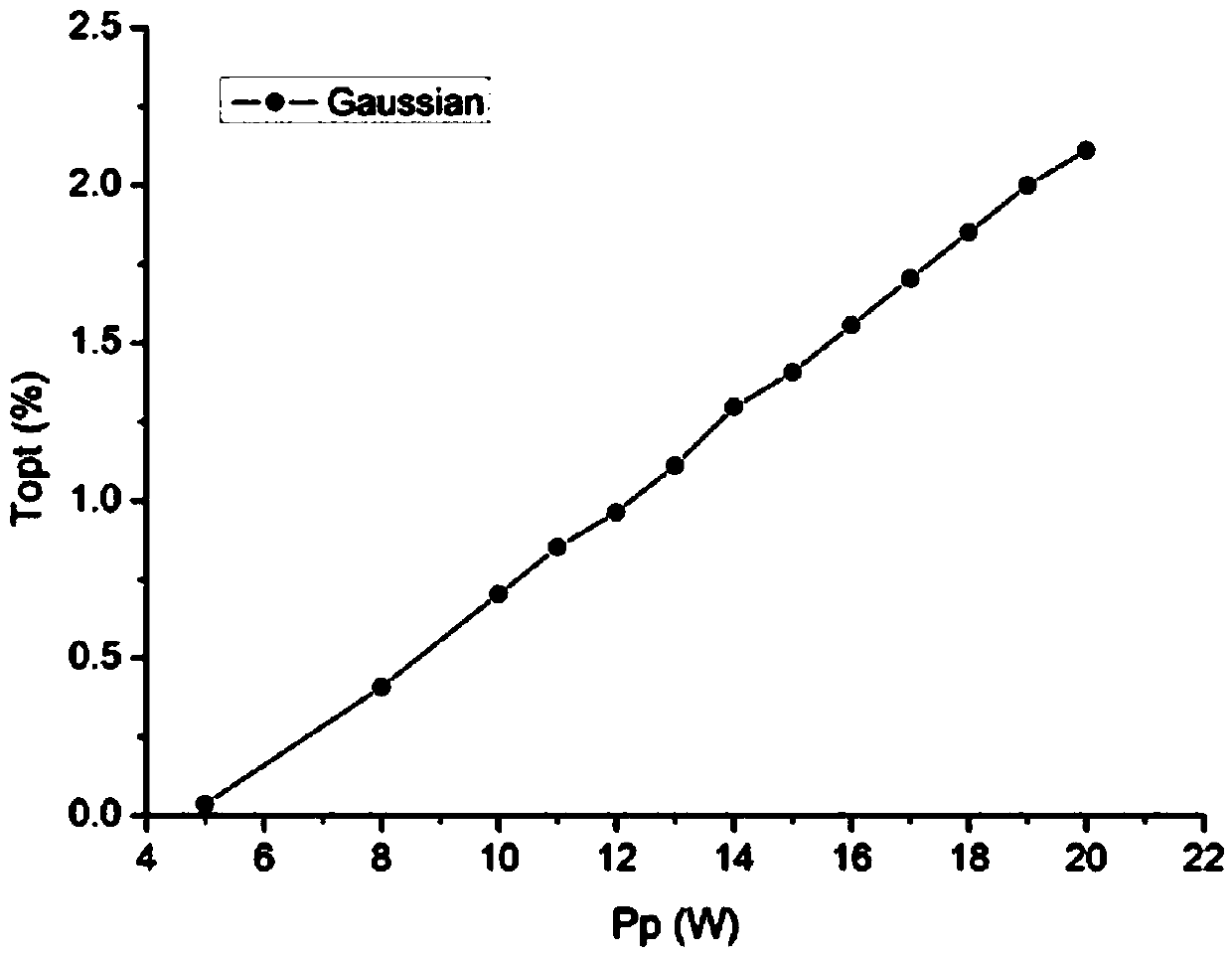

[0047] In this embodiment, the above optimization method is applied to a mid-infrared continuous operation optical parametric oscillator (OPO) with single resonance of signal light. The mid-infrared optical parametric oscillator involved in the embodiment is based on a quasi-phase-matched MgO:PPLN crystal. This type of optical parametric oscillator has wide spectral matching linewidth and good temperature and wavelength tuning characteristics, so it is very suitable for the optimization method involved in the present invention. The specific optimization steps are as follows:

[0048] Step 1: The design goal is to produce a 3.0μm band mid-infrared laser output with an output power of not less than 2W. According to the energy conservation of the three-wave interaction under the quasi-phase matching condition and the momentum conservation relationship un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com