Coating film formation method, base material with transparent conducting film, device and electronic apparatus

A technology of transparent conductive film and coating film, which is applied in the fields of coating film formation, substrates with transparent conductive film, devices and electronic equipment, and can solve the problems of poor material use efficiency, high cost and high price of ITO transparent electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162] (Examples 1 to 6, Comparative Example 1)

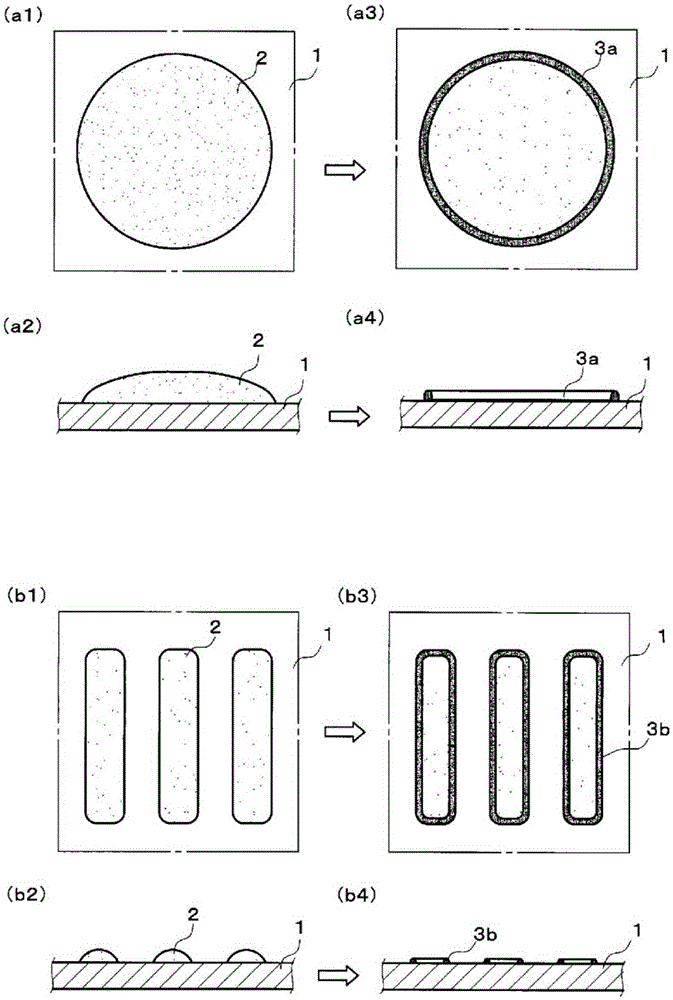

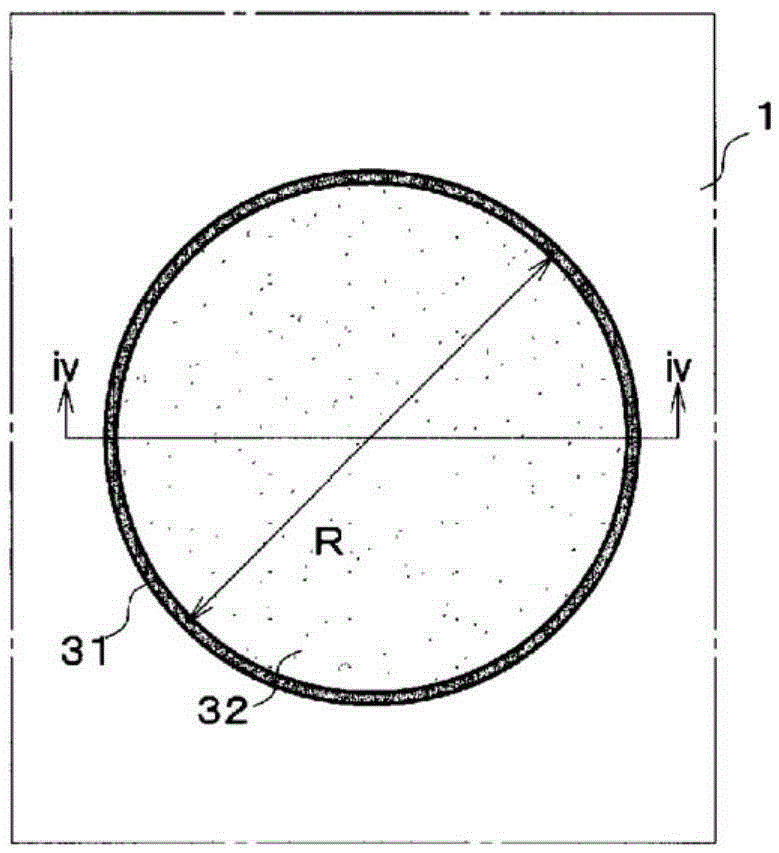

[0163] Using an inkjet head ("KM512L" manufactured by Konica Minolta Corporation; standard droplet volume: 42 pl), the ink of the composition shown in Table 1 was used to attach the droplet to PS-1M manufactured by Shinko Denkisou Co., Ltd. A circular pattern (coating pattern) was formed on the surface of the above-mentioned clear hard coat layer of the PET film (base material) with a clear hard coat layer treated by corona discharge. This pattern was dried, and the solid content was deposited on the edge to form a plurality of fine annular patterns (coating films) with a diameter of 70 μm. These ring-shaped patterns are arranged in a grid at intervals of 282 μm to form an overall pattern ( Figure 7 ). Here, adjacent annular patterns overlap and join each other at edge portions.

[0164] Table 1 shows the results of measuring the total light transmittance and conductivity of the obtained patterns.

Embodiment 7

[0166] By screen printing, using inks of the composition shown in Table 2, line width / space width = 70 μm / 211 μm, and corona discharge-treated PS-1M manufactured by Shinko Electric Keiseo Co., Ltd. with different surface energies A striped pattern (coating pattern) was formed on the transparent hard-coat surface of the transparent hard-coat-attached PET film (substrate). The pattern is dried to form a fine striped pattern (coating film) ( Figure 8 ).

[0167] Table 2 shows the results of measuring the total light transmittance and conductivity of the obtained patterns.

Embodiment 8~13、 comparative example 2

[0169] Using an inkjet head (manufactured by Konica Minolta "KM512L"; the standard droplet volume is 42 pl), using the ink of the composition shown in Table 1, the pitch in the nozzle row direction is 211 μm, and the dot pitch in the scanning direction is 50 μm. The transparent hard-coat surface of the PET film (base material) with a transparent hard-coat layer which corona-discharge-processed using PS-1M by Shinko Denkisou Co., Ltd. was carried out. The respective droplets on the substrate were united to form a striped pattern (coating pattern) similar to that of Example 7. By drying the pattern, the solid content is deposited on the edge to form a fine striped pattern (coating film) ( Figure 8 ).

[0170] Table 2 shows the results of measuring the total light transmittance and conductivity of the obtained patterns.

[0171]

[0172] ・Substrate heating method: After the coating film is formed, the substrate is heated with a heating plate.

[0173] · Substrate surface te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com