Energy-efficient desulfurization and denitrification dust removal system

A desulfurization, denitrification, and dust removal system technology, which is applied in the direction of lighting and heating equipment, combined devices, and separation of dispersed particles, to achieve the effects of avoiding the temperature drop of flue gas, effective denitrification operation, and low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

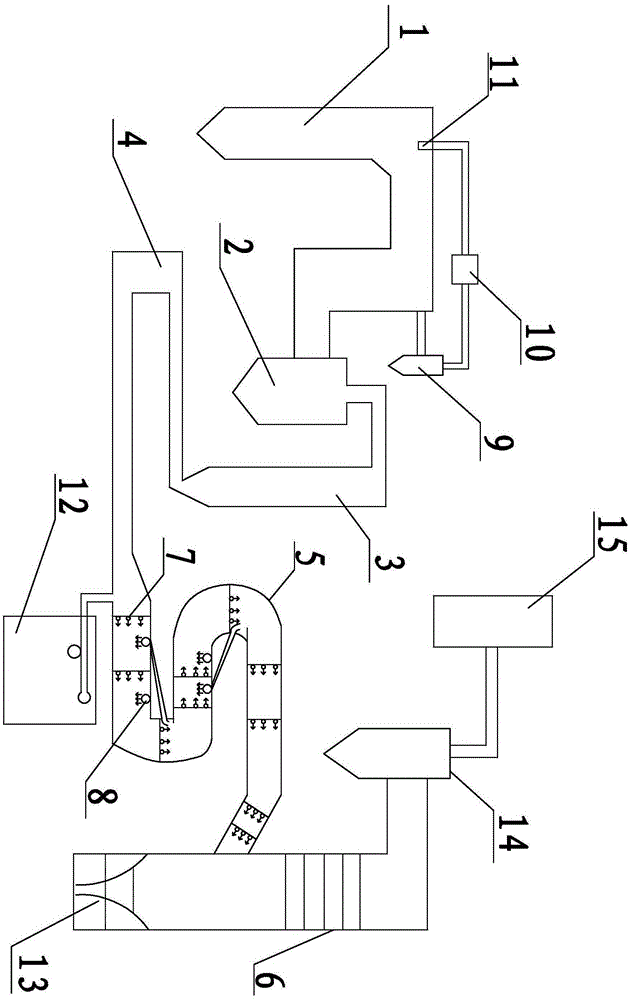

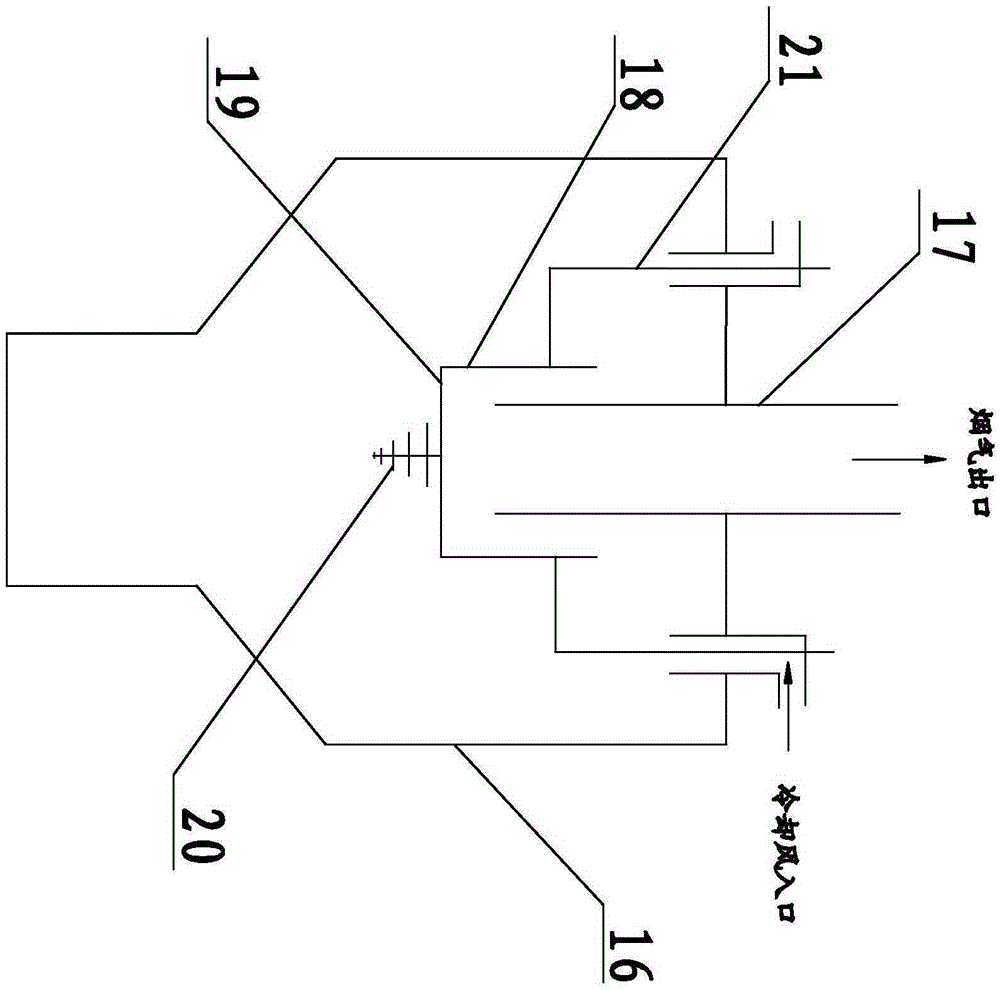

[0034]As shown in the figure, a high-efficiency energy-saving desulfurization, denitrification and dust removal system disclosed by the present invention includes a cyclone dust collector including a burner, a high-temperature electric cyclone dust collector 9, an SCR reactor 3, and an air preheating system. 4, flue 5, absorption tower 6, main spray 7, auxiliary spray 8, medium and high temperature electric cyclone dust collector 92, nitrogen mixer 10, refractory material and metal material composite spray gun 11 or ammonia cake, A low pH value slurry circulation pool 12, a high pH value slurry circulation pool 13, a wet electric cyclone dust collector 14, and a chimney 15.

[0035] The cyclone dust collector including the burner is located above the burner and below the large screen, and a cyclone dust removal top cover composed of refractory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com