Composite cold pressing, synthesizing and cementing carrier roller

A synthetic rubber and composite technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., to achieve the effects of light weight, improved overall performance, and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

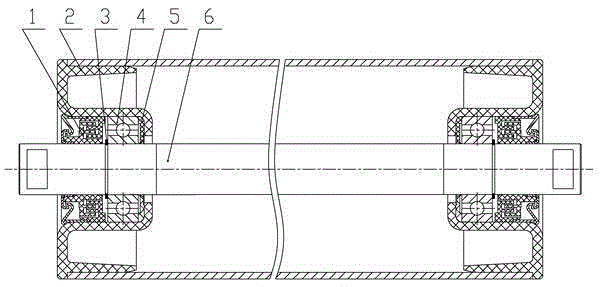

[0020] Referring to the accompanying drawings, a composite cold-pressed synthetic adhesive roller includes a combined sealing device 1, a tube seat 2, a retaining ring 3, a bearing 4, a spacer ring 5, and a shaft 6. The shaft 6 penetrates the tube seat 2 and is connected to the shaft. 6. Install the isolation ring 5 and the bearing 4 at both ends, and the bearing 4 is fixed on both ends of the shaft 6 with the retaining ring 3;

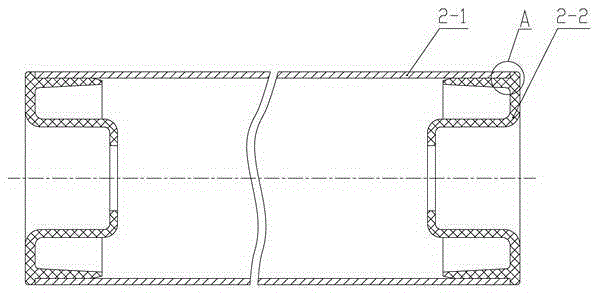

[0021] The tube seat 2 is made of a tube 2-1 and a bearing seat 2-2 which are bonded together by cold pressing and synthetic bonding. The material of the tube 2-1 is a straight seam electric welded steel pipe specially used for ultra-high precision idlers, and is treated with anti-rust inside and outside the tube. Manufactured; the bearing seat 2-2 is made of polyoxymethylene, which is formed by one-time injection molding.

[0022] The cold-pressed synthetic bonding process is to use special equipment to saw off the pipe 2-1 to meet the requirements o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com