Plate blank positioning device for transverse-moving trolley

A technology for traversing trolleys and positioning devices, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyors. It can solve the problems of damage to electronic components of laser detectors, easy sending of false action signals, and increased production costs. The effect of reducing maintenance and updating costs, accurate positioning, and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

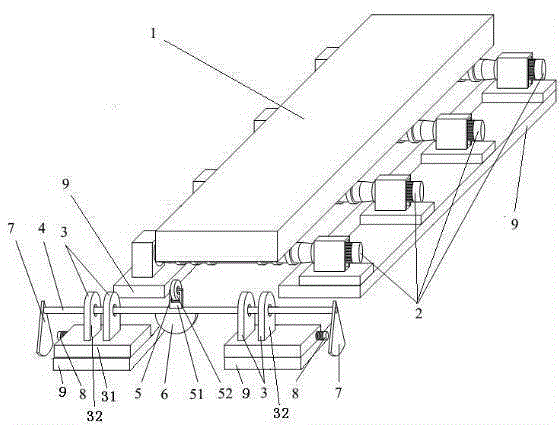

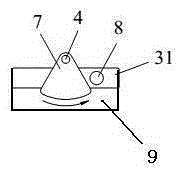

[0018] Such as figure 1 As shown, a slab positioning device for a traversing trolley includes a traversing trolley, wheels (not shown) for lateral movement are arranged under the frame 9 of the traversing trolley, and the conveying rollers on the trolley and the platform The moving direction of the car is arranged vertically, between the two conveying rollers 2 at the output end of the conveying roller table (in order to facilitate the observation of the structure of the present invention, only the conveying roller 2 on the opposite side is shown, and the conveying roller 2 on the side is not shown). A support base 3, its base plate 31 is welded with vehicle frame 9 two ends respectively or fixed with bolts, and described support base 3 is made of base plate 31 and its upper support plate 32, and support plate 32 is provided with shaft hole, in order to strengthen this device In this embodiment, each supporting base 3 is provided with two supporting plates 32 parallel to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com