A method for preparing iron red and recovering silver from alumite slag

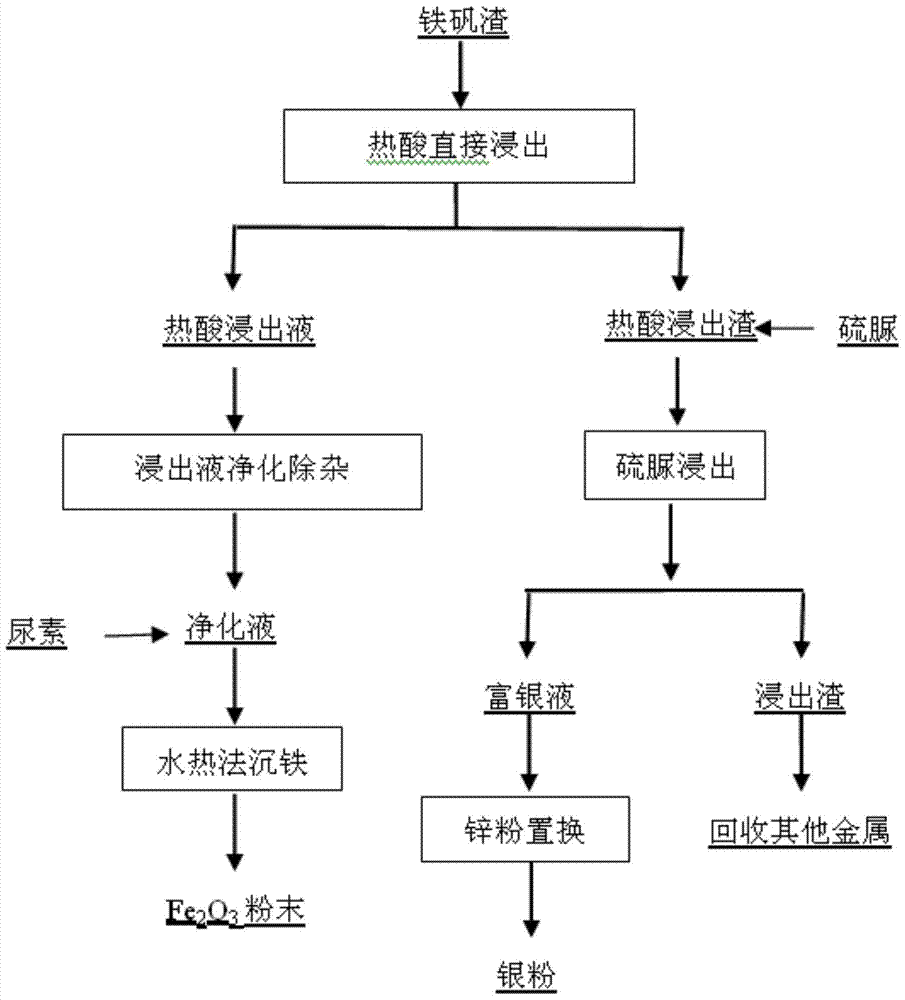

A technology of jarosite slag and iron red, which is applied in the field of comprehensive recovery of hydrometallurgy, and can solve the problems of high energy consumption of jarosite slag, long-term stacking treatment of jarosite slag to pollute the environment, and insufficient recycling of valuable metals and iron resources. and other problems, to achieve the effect of high acidity and improved leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The zinc-ferrosite slag from a Chifeng smelter in Inner Mongolia was used as the raw material, and its elemental composition is shown in Table 1.

[0031] Table 1 Main element composition of raw materials

[0032] element Fe Zn Pb Cu Cd Ag Content w / % 25.9 3.6 1.7 0.22 0.097 518.5 element S mn Si acid As Na K Content w / % 10.1 0.92 1.3 0.77 0.61 0.23

[0033] Note: The unit of silver content is g / t

[0034] (1) Weigh 400g of alumina slag, according to the volume / mass ratio (mL / g) 2:1, the amount of sulfuric acid is 1.5 times of the theoretical amount, react at a temperature of 60°C for 2h, filter to obtain hot acid leaching filtrate and hot Acid leaching slag;

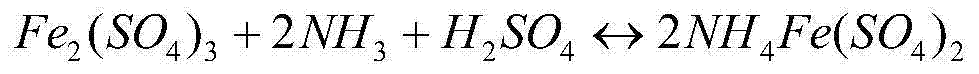

[0035] (2) The hot acid leaching solution is replaced by iron powder to remove copper, sulfide to remove lead, cadmium, arsenic, H 2 o 2 Oxidation, to obtain a purification solution, the purification solution contains 88.5g / L of iron;

[0036] (3...

Embodiment 2

[0041] The zinc-ferrosite slag from a Chifeng smelter in Inner Mongolia was used as the raw material, and its elemental composition is shown in Table 1.

[0042] (1) Take by weighing 400g of vitriol slag, according to the volume / mass ratio (mL / g) 4:1, the amount of sulfuric acid is 1.0 times of the theoretical amount, react at a temperature of 80°C for 4h, filter to obtain hot acid leaching filtrate and Hot acid leaching residue;

[0043] (2) The hot acid leaching solution is replaced by iron powder to remove copper, sulfide to remove lead, cadmium, arsenic, H 2 o 2 Oxidation, to obtain a purification solution, the purification solution contains 103.0g / L of iron;

[0044] (3) The purification liquid is adjusted to PH to 1.5 by lime milk, 1.5 times the theoretical amount of urea is added, and the reaction time is 2 hours at a temperature of 180° C. to obtain the product iron red;

[0045] (4) The hot acid leaching slag was obtained under the conditions of a liquid-solid rati...

Embodiment 3

[0049] The zinc-ferrosite slag from a Chifeng smelter in Inner Mongolia was used as the raw material, and its elemental composition is shown in Table 1.

[0050] (1) Take by weighing 400g of vitriol slag, according to the volume / mass ratio (mL / g) 6:1, the amount of sulfuric acid is 1.8 times of the theoretical amount, react at a temperature of 100°C for 1h, filter to obtain hot acid leaching filtrate and Hot acid leaching residue;

[0051] (2) The hot acid leaching solution is replaced by iron powder to remove copper, sulfide to remove lead, cadmium, arsenic, H 2 o 2 Oxidation, to obtain a purification solution, the purification solution contains 118.6g / L of iron;

[0052] (3) The purified solution is neutralized with milk of lime to adjust the pH to 0.5, add urea twice the theoretical amount, and react for 3 hours at a temperature of 220° C. to obtain the product iron red;

[0053] (4) Reacting the hot acid leaching residue at a liquid-solid ratio (mL / g) of 12:1, a thioure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com