Self-assembly orderly patterning growing preparing method of rubrene films

A self-assembly, rubrene technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of reducing film mobility, destroying film structure, and high process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

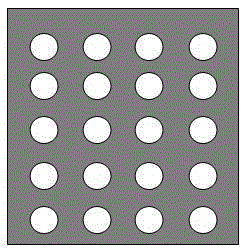

Image

Examples

Embodiment Construction

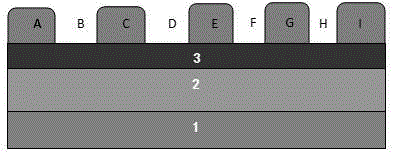

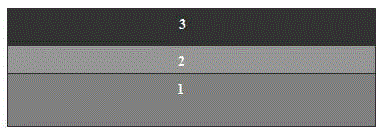

[0008] Such as image 3 As shown, Si substrate (1), the substrate temperature is 20℃; SiO 2 The insulating layer (2) has a thickness of 300nm; the rubrene layer (3) has a thickness of 50nm.

[0009] The specific realization process: the substrate is composed of substrate Si (1) and a layer of 300nm thick SiO on its surface 2 (2) Composition; clean the substrate and put it into the reaction chamber of the seven-station OEL / EL photoelectric thin film joint preparation system; the vacuum degree of the reaction chamber is evacuated to less than 6.0×10 -4 Pa; a layer of rubrene was vacuum evaporated on the substrate with a thickness of 50nm, and the substrate temperature was 20°C. First, it is deposited according to the evaporation rate of 2nm / min, with a thickness of about 10nm, on SiO 2 The dot-like aggregation of rubrene molecules is formed on the layer; then stop for 5 minutes to realize the self-assembly arrangement of molecules; then continue to deposit at the evaporation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com