A kind of chemical fiber ring blowing cooling method

A cooling method and chemical fiber technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of slow solidification of spinning liquid, affecting spinning quality, and easy sticking of filaments, etc., to achieve uniformity And the effect of rapid cooling, improving environmental health, and high uniform energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

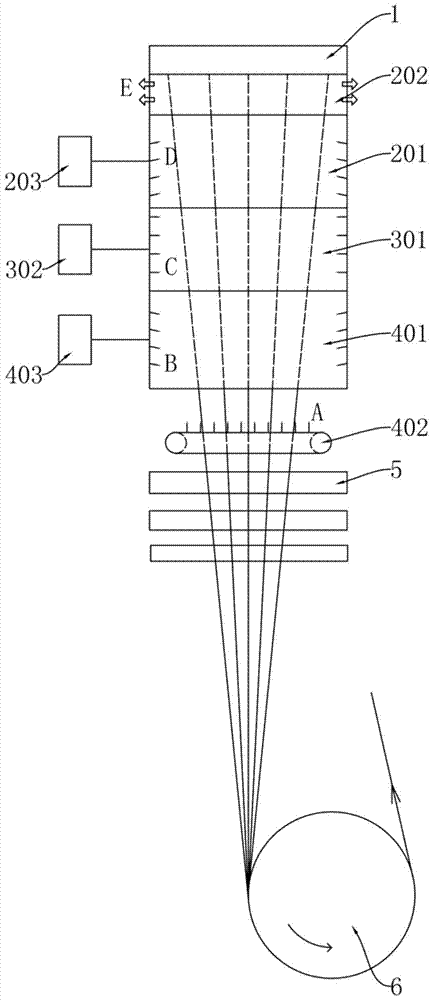

[0052] A chemical fiber ring blowing cooling method described in this embodiment is to cool and solidify the thin flow of liquid chemical fiber raw materials extruded from the spinneret assembly 1, the spinning temperature is 275°C, the spinning speed is 2900m / min, and the ring blowing cooling molding includes: Three continuous cooling zones from top to bottom: the first cooling zone, the second cooling zone and the third cooling zone.

[0053] The first cooling zone: it is the air upflow cooling zone, including the first ring air pipe 201 and the exhaust ring 202, the angle of the air outlet D of the first ring air pipe is upward 10°, that is, the wind direction of the air outlet D of the first ring air pipe The angle with the horizontal plane is 10°. The exhaust ring 202 is located between the spinneret assembly 1 and the first ring air pipe 201, the temperature of the air outlet from the first ring air pipe is 23°C, the wind speed is 0.294m / s, and the air humidity is 80%. ...

Embodiment 2

[0059] A chemical fiber ring blowing cooling method described in this embodiment is to cool and solidify the thin stream of liquid chemical fiber raw material extruded from the spinneret assembly 1, the spinning temperature is 275°C, the spinning speed is 2800m / min, and the ring blowing cooling molding includes: Three continuous cooling zones from top to bottom: the first cooling zone, the second cooling zone and the third cooling zone.

[0060] The first cooling zone: it is the air upflow cooling zone, including the first ring air duct 201 and the exhaust ring 202, the angle of the air outlet D of the first ring air duct is upward 25°, that is, the wind direction of the air outlet D of the first ring air duct The angle with the horizontal plane is 25°. The air exhaust ring 202 is located between the spinneret assembly 1 and the first ring air duct 201. The air outlet temperature of the first ring air duct is 22° C., the wind speed is 0.32 m / s, and the air humidity is 81%. Th...

Embodiment 3

[0066] A chemical fiber ring blowing cooling method described in this embodiment is to cool and solidify the thin flow of liquid chemical fiber raw materials extruded from the spinneret assembly 1, the spinning temperature is 275°C, the spinning speed is 2900m / min, and the ring blowing cooling molding includes: Three continuous cooling zones from top to bottom: the first cooling zone, the second cooling zone and the third cooling zone.

[0067] The first cooling zone: it is the air upflow cooling zone, including the first ring air duct 201 and the exhaust ring 202, the angle of the air outlet D of the first ring air duct is upward 15°, that is, the wind direction of the air outlet D of the first ring air duct The angle with the horizontal plane is 15°. The air exhaust ring 202 is located between the spinneret assembly 1 and the first ring air pipe 201, the air outlet temperature of the first ring air pipe is 23° C., the wind speed is 0.30 m / s, and the air humidity is 80%. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com