System and method for reducing emission of oxynitride of combustion equipment

A technology of combustion equipment and nitrogen oxides, which is applied in the direction of combustion method, combustion equipment, combustion type, etc., can solve the problems of fluctuation of nitrogen oxide emission value, ratio fluctuation, combustion instability, etc., to reduce nitrogen oxide emissions and ensure Safe and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

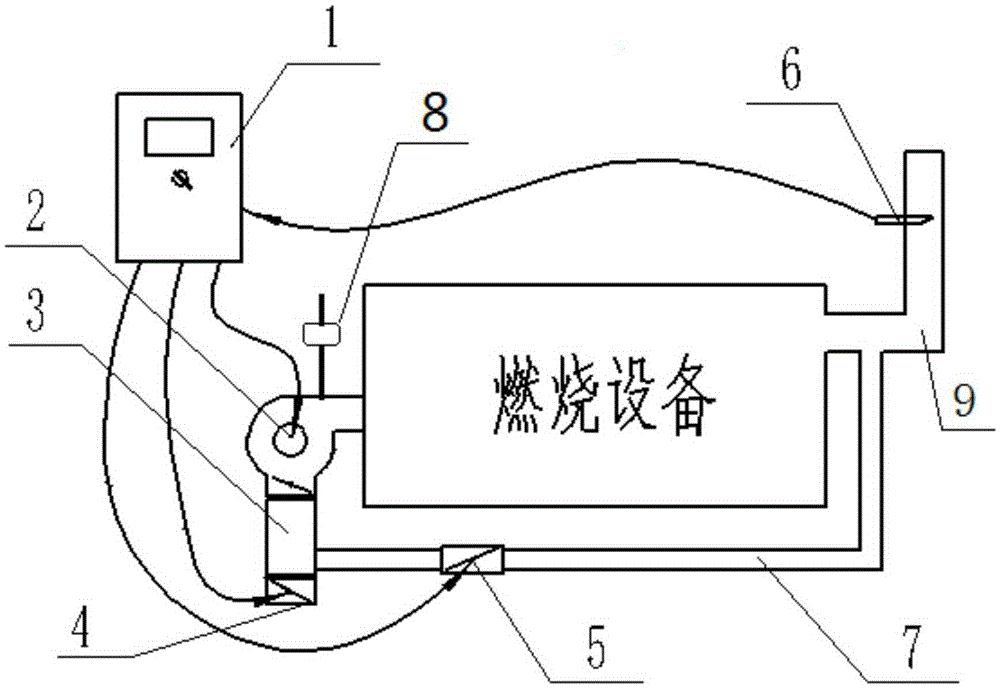

[0030] A system for reducing NOx emissions from combustion equipment such as figure 1As shown, it includes the existing combustion equipment with a burner 2 and a flue 9. The burner 2 contains a burner and is connected to a blower. The blower has its own air door adjustment baffle. A gas flow regulating valve 8 is installed, and the gas flow regulating valve 8 controls the fuel flow flowing into the burner 2, and a flue gas O is installed in the flue 9. 2 , CO, NOx component concentration sensor 6. On this basis, the present invention adds an air mixer 3 and a low-nitrogen controller 1 as an on-site control terminal, and the air inlet of the burner 2 is connected in series with the air outlet of the air mixer 3 . The air mixer 3 has two air inlets, one of which is connected to the combustion-supporting air pipe to introduce combustion-supporting air, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com