A clean discharge system and method for a fluidized bed boiler

A fluidized bed boiler and emission system technology, applied in fluidized bed combustion equipment, chemical instruments and methods, combustion methods, etc., can solve the problems of reducing average cost, high ammonia escape, and difficulty in desulfurization, and achieve SO2 emission Control, reduce the reaction volume, use the effect of a long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

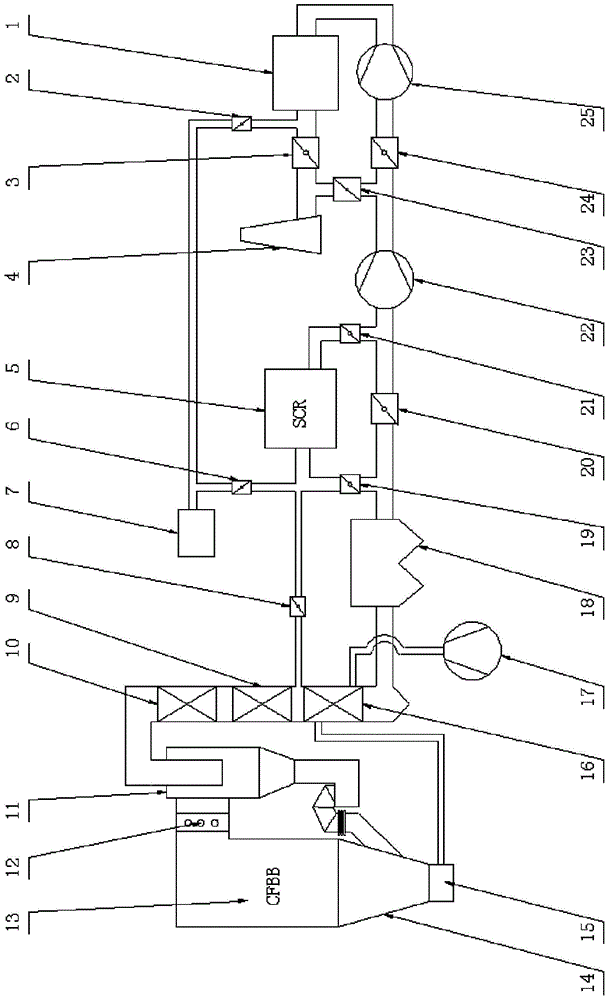

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0031] A clean discharge method for a fluidized bed boiler according to the present invention is mainly realized through the following process steps:

[0032] In-furnace desulfurization in the dense-phase area of the fluidized bed boiler;

[0033] Perform primary denitrification based on SNCR at the furnace outlet;

[0034] After the first desulfurization and first denitrification in the furnace, the flue gas is dedusted and then the temperature is raised for the second denitrification based on SCR;

[0035] The flue gas after secondary denitrification is sent to the desulfurization system for secondary desulfurization.

[0036] In order to realize the above method and effectively adapt to various actual working conditions, the present invention also provides a clean discharge system for a fluidized bed boiler, such as figure 1 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com