Flue gas desulfurization system and desulfurization method thereof

A desulfurization system and flue gas technology, applied in the flue gas desulfurization system and its desulfurization field, can solve the problems of low desulfurization agent recycling efficiency, complex equipment, and low desulfurization process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

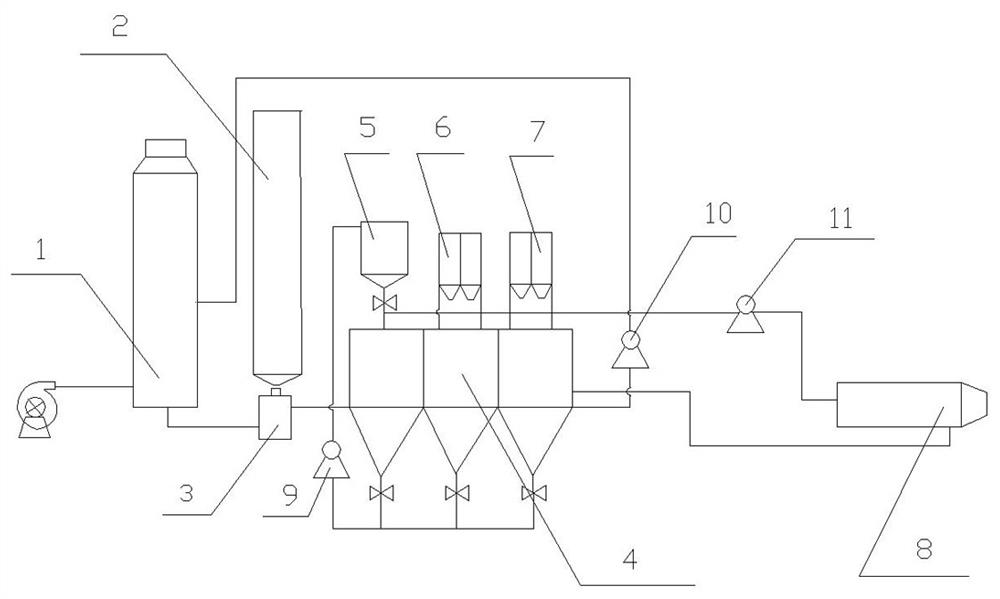

[0034] Reference attached figure 1 , the flue gas desulfurization system of the present invention includes a desulfurization and dust removal tower 1, an automatic lime storage charging tower 2, a reactor 3, an oxidation tank 5, a catalyst preparation tank 7, a catalyst storage and delivery tank 6, an integrated equipment box 4 and a filter press 8; the air inlet at the bottom of the desulfurization and dust removal tower 1 is communicated with the fan (the flue gas is passed into the desulfurization tower from the air inlet at the lower part of the desulfurization tower through the fan), and the drainage hole at the bottom of the desulfurization and dust removal tower 1 is communicated with the water inlet of the reactor 3, and the reactor 3 The top feeding port is communicated with the lime storage automatic feeding tower 2, the water outlet of the reactor 3 is communicated with the water inlet of the integrated equipment box 4, and the water outlet of the integrated equipmen...

Embodiment 2

[0037] Reference attached figure 1 , the flue gas desulfurization system of the present invention includes a desulfurization and dust removal tower 1, an automatic lime storage charging tower 2, a reactor 3, an oxidation tank 5, a catalyst preparation tank 7, a catalyst storage and delivery tank 6, an integrated equipment box 4 and a filter press 8; the air inlet at the bottom of the desulfurization and dust removal tower 1 is communicated with the fan (the flue gas is passed into the desulfurization tower from the air inlet at the lower part of the desulfurization tower through the fan), and the drainage hole at the bottom of the desulfurization and dust removal tower 1 is communicated with the water inlet of the reactor 3, and the reactor 3 The top feeding port is communicated with the lime storage automatic feeding tower 2, the water outlet of the reactor 3 is communicated with the water inlet of the integrated equipment box 4, and the water outlet of the integrated equipmen...

Embodiment 3

[0040] Reference attached figure 1 , the flue gas desulfurization system of the present invention includes a desulfurization and dust removal tower 1, an automatic lime storage charging tower 2, a reactor 3, an oxidation tank 5, a catalyst preparation tank 7, a catalyst storage and delivery tank 6, an integrated equipment box 4 and a filter press 8; the air inlet at the bottom of the desulfurization and dust removal tower 1 is communicated with the fan (the flue gas is passed into the desulfurization tower from the air inlet at the lower part of the desulfurization tower through the fan), and the drainage hole at the bottom of the desulfurization and dust removal tower 1 is communicated with the water inlet of the reactor 3, and the reactor 3 The top feeding port is communicated with the lime storage automatic feeding tower 2, the water outlet of the reactor 3 is communicated with the water inlet of the integrated equipment box 4, and the water outlet of the integrated equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com