A device and method for removing zero-valent mercury in flue gas by in-situ discharge activation oxidation

A zero-valent mercury and flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve a large number of problems, increase the cost of mercury removal, increase the risk of secondary pollution, etc., and achieve low cost and increase. Equipment cost and the effect of less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

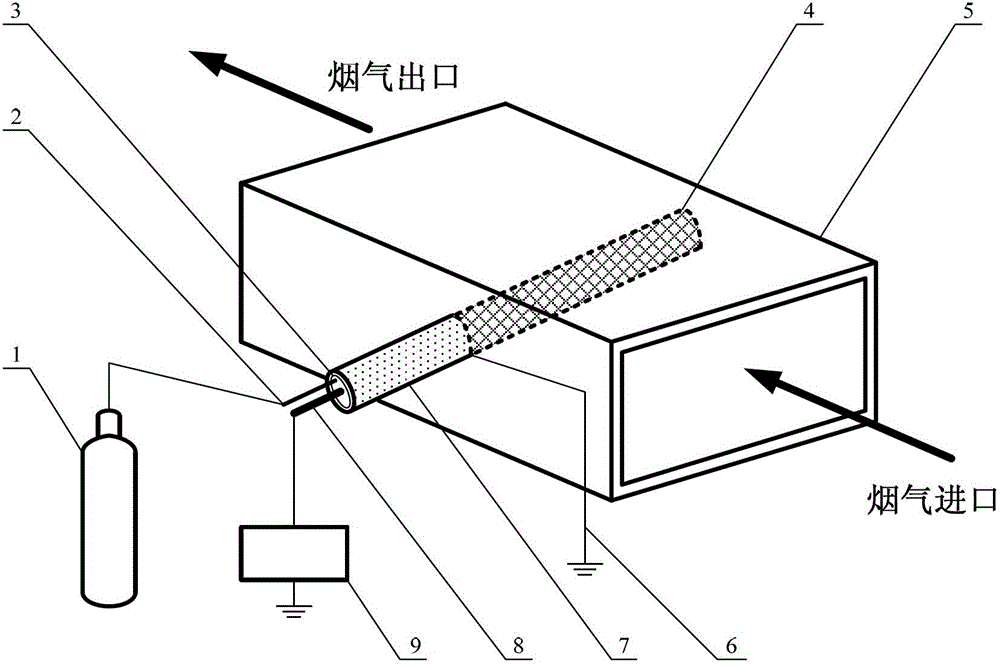

Image

Examples

Embodiment 1

[0038] In this embodiment, a square stainless steel device is used as a simulated flue, and the length, width, and height of the flue are 2000 mm, 400 mm, and 400 mm, respectively. An air heating device is installed in the upstream of the flue, and the hot simulated flue gas ([NO]=200ppm, [Hg 0 ] = 20μg / m 3 , [SO 2 ]=1000ppm, the rest is hot air at 150℃ heated by electric furnace) at 100m 3 The flow rate of / h is continuously passed into the flue. A row of five corona discharge devices is arranged horizontally on the side center line of the flue. The diameter of the corona discharge devices is 100 mm, and the distance between the centers of the corona discharge devices is 400 mm. The main body of the corona discharge device is made of ceramic tube, the thickness of the ceramic tube wall is 0.5mm, the structure of the discharge electrode is single needle, and the grounding pole is a stainless steel filter mesh sleeve, which is wrapped on the outer surface of the main body of...

Embodiment 2

[0040] The device and method are the same as in Example 1, except that the mercury removal agent is changed to gaseous hydrogen bromide, and after hydrogen bromide is sprayed into the flue gas, the concentration in the simulated flue gas is 2ppmv. When no voltage is applied, the removal efficiency of zero-valent mercury in flue gas is 40%; gradually adjust the voltage to 8.0kV, the removal efficiency of zero-valent mercury reaches about 75%; further adjust the voltage to 9.0kV, zero-valent mercury The removal efficiency of mercury reached about 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com