Multivariable deduction, predication and control method for middle-speed coal pulverizer

A technology of predictive control and coal mill, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the unstable control of coal mill outlet temperature, affect the operation safety and economy, load response and Issues such as large command delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

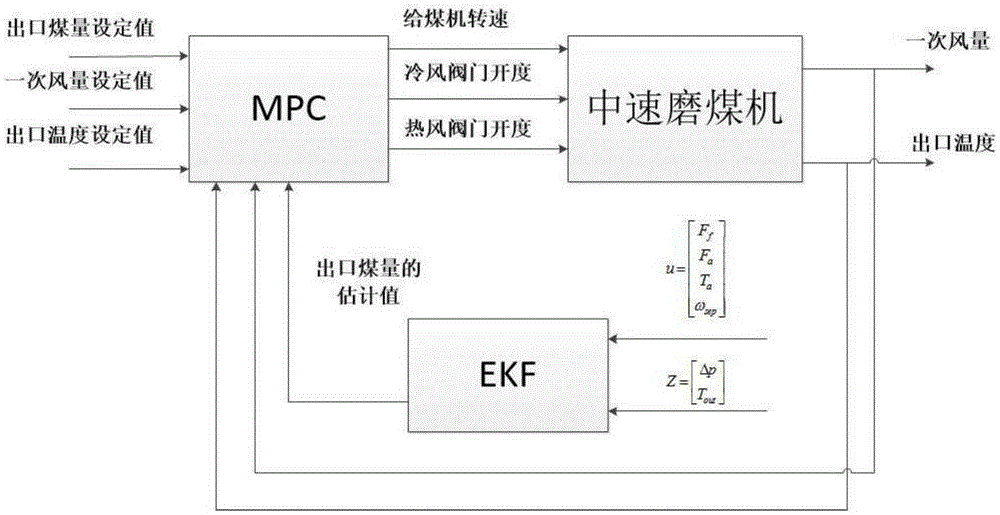

[0089] exist figure 1 Among them, the model predictive control system (MPC) has three controlled quantities, which are the exported coal volume f out , outlet temperature T out and primary air volume F a ; There are 3 control variables U in the system, which are the coal feeder belt speed ω f , cold air valve opening μ c and opening degree of hot air valve μ h . The extended Kalman filter estimator (EKF) is used to estimate the coal output of the pulverizer.

[0090] The multivariable inference predictive control method of the medium-speed coal mill of the present invention comprises the following steps:

[0091] S1: Establish the model of the medium-speed coal mill:

[0092] The primary air volume F of the medium-speed pulverizer a , Coal mill inlet air temperature T a and the instantaneous flow rate F of the coal feeder f They are:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com