Low-ripple switched-capacitor common-mode feedback structure

A technology of common-mode feedback and switched capacitors, applied in improving amplifiers to reduce temperature/supply voltage changes, differential amplifiers, improving amplifiers to expand bandwidth, etc., can solve the impact of fully differential operational amplifiers, the output cannot be stable, and common-mode feedback There are problems such as ripple in the output, so as to achieve the effects of small ripple, increased unity gain bandwidth, and improved output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a low-ripple switched capacitor common-mode feedback structure. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

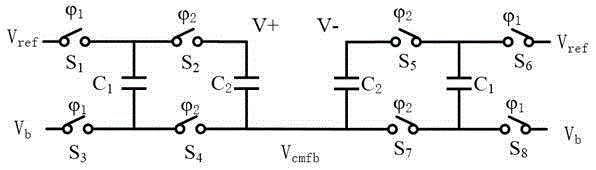

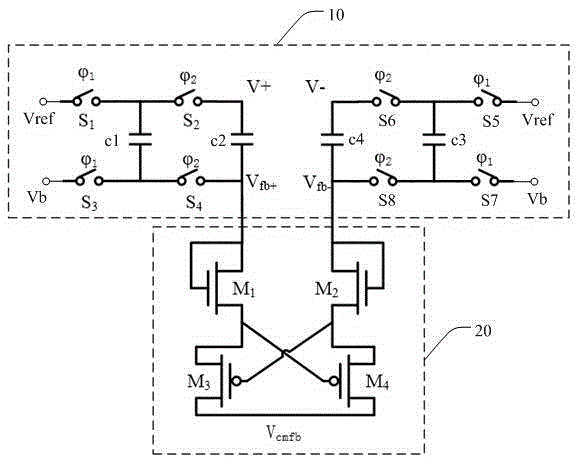

[0031] see figure 2 , the low-ripple switched capacitor common-mode feedback structure provided by the present invention includes a common-mode operation switched capacitor circuit 10 and a filter circuit 20, and the common-mode operation switched capacitor circuit 10 includes a first capacitor c1, a second capacitor c2, a third capacitor c3, fourth capacitor c4, first switch S1, second switch S2, third switch S3, fourth switch S4, fifth switch S5, sixth switch S6, seventh switch S7 and eighth sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com