Method for preparing stainless steel with antibacterial and anticancer properties by using rhodium complex

A rhodium complex, stainless steel technology, applied in the field of stainless steel, can solve problems such as poor water solubility, patient danger, solvent residue, etc., and achieve the effect of molecular stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

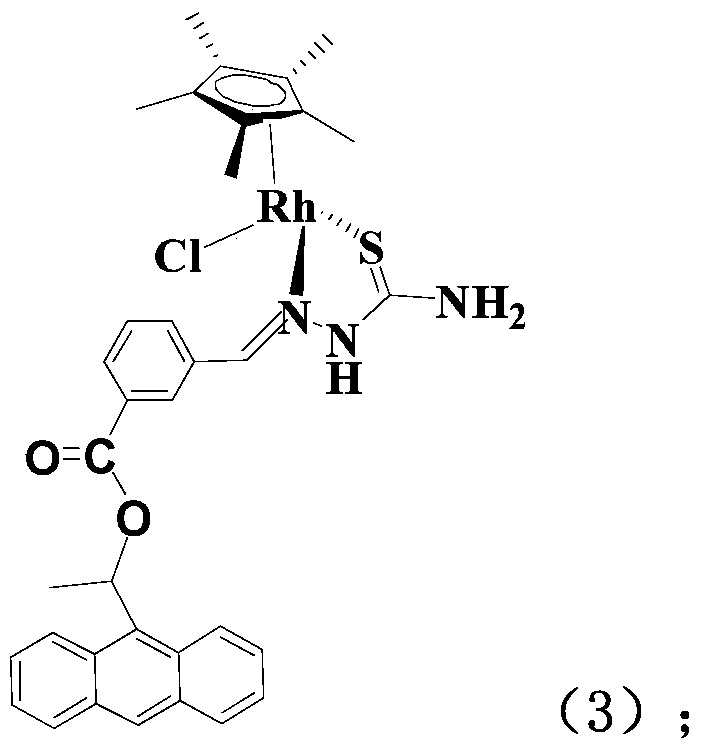

[0025] This scheme utilizes rhodium complex to prepare the method for the stainless steel with antibacterial and anticancer performance, comprises the following steps:

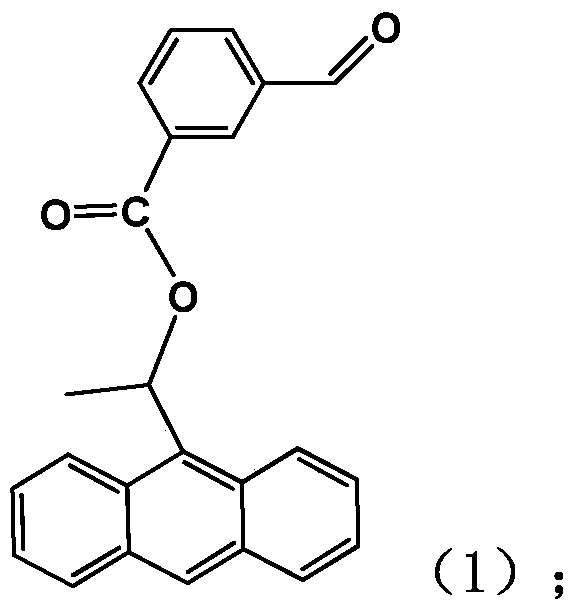

[0026] 1) Dissolve 4 parts by weight of m-carboxybenzaldehyde in 11 parts by weight of toluene, add 12 parts by weight of 1-(9-anthracenyl)ethanol and 1 part by weight of sulfuric acid with a concentration of 98%, and heat to 110° C. and stir and reflux for 2 hours , then the filtrate was spin-dried, added 6 parts by weight of ethyl acetate for extraction, repeated the extraction process of ethyl acetate 4 times, combined the ethyl acetate layer solution, then added 11 parts by weight of anhydrous potassium carbonate and spin-dried to obtain a compound having the formula (1 ), i.e. m-anthracenoxybenzaldehyde;

[0027]

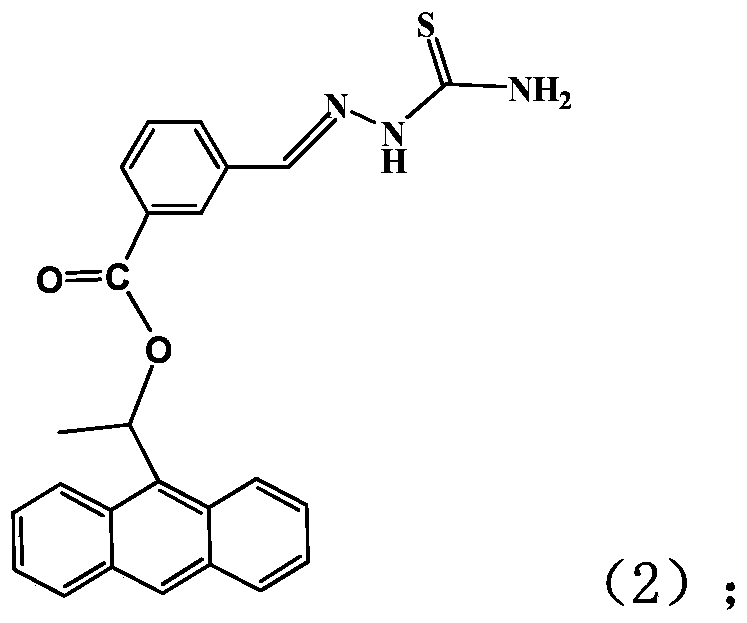

[0028] 2) Dissolve 5 parts by weight of m-anthroxyylbenzaldehyde in 12 parts by weight of absolute ethanol, add 3 parts by weight of thiosemicarbazide, stir under reflux at 65°C, react for 6...

Embodiment 2

[0036] This scheme utilizes rhodium complex to prepare the method for the stainless steel with antibacterial and anticancer performance, comprises the following steps:

[0037] 1) Dissolve 3 parts by weight of m-carboxybenzaldehyde in 10 parts by weight of toluene, add 10 parts by weight of 1-(9-anthracenyl)ethanol and 0.5 parts by weight of sulfuric acid with a concentration of 98%, and heat to 100° C. and stir and reflux for 1 h , then the filtrate is spin-dried, adding 5 parts by weight of ethyl acetate for extraction, repeating the extraction process of ethyl acetate 3 times, combining the ethyl acetate layer solution, then adding 10 parts by weight of anhydrous potassium carbonate and spinning-drying to obtain a compound having the formula (1 ), i.e. m-anthracenoxybenzaldehyde;

[0038]

[0039] 2) Dissolve 4 parts by weight of m-anthroxyylbenzaldehyde in 10 parts by weight of absolute ethanol, add 1 part by weight of thiosemicarbazide, stir under reflux at 60°C, react...

Embodiment 3

[0047] This scheme utilizes rhodium complex to prepare the method for the stainless steel with antibacterial and anticancer performance, comprises the following steps:

[0048]1) Dissolve 5 parts by weight of m-carboxybenzaldehyde in 15 parts by weight of toluene, add 15 parts by weight of 1-(9-anthracenyl)ethanol and 1.5 parts by weight of sulfuric acid with a concentration of 98%, and heat to 120° C. and stir and reflux for 3 hours , then the filtrate is spin-dried, adding 10 parts by weight of ethyl acetate for extraction, repeating the extraction process of ethyl acetate 5 times, merging the ethyl acetate layer solution, then adding 15 parts by weight of anhydrous potassium carbonate and spinning-drying to obtain a compound having the formula (1 ), i.e. m-anthracenoxybenzaldehyde;

[0049]

[0050] 2) Dissolve 10 parts by weight of m-anthracenoxyacylbenzaldehyde in 20 parts by weight of absolute ethanol, add 5 parts by weight of thiosemicarbazide, reflux and stir at 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com