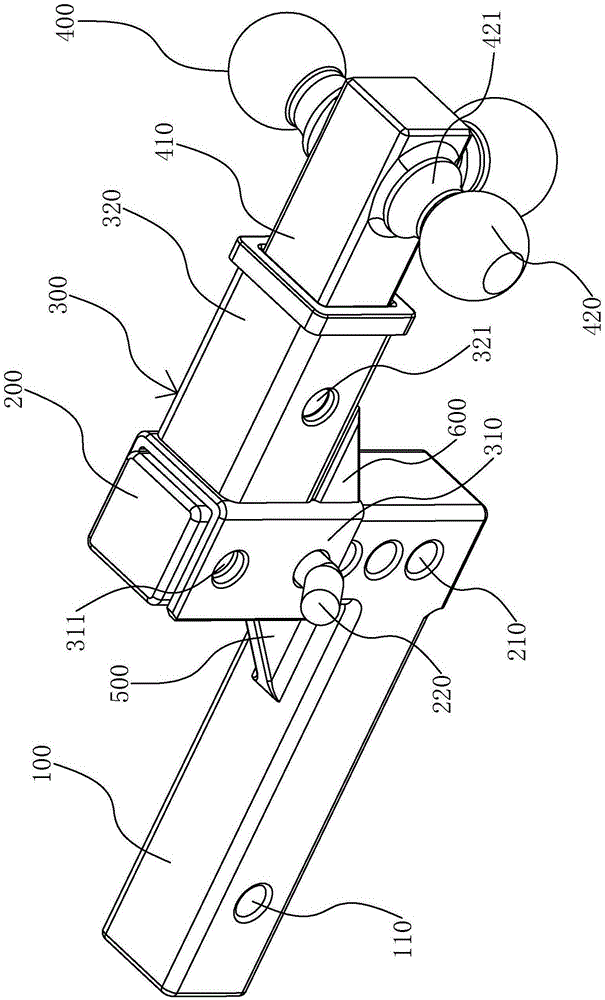

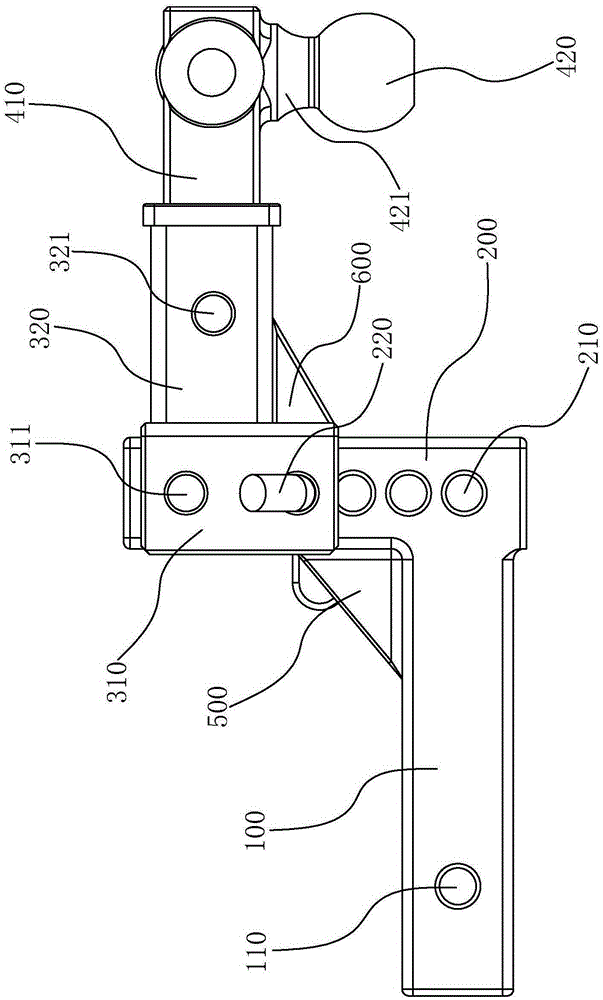

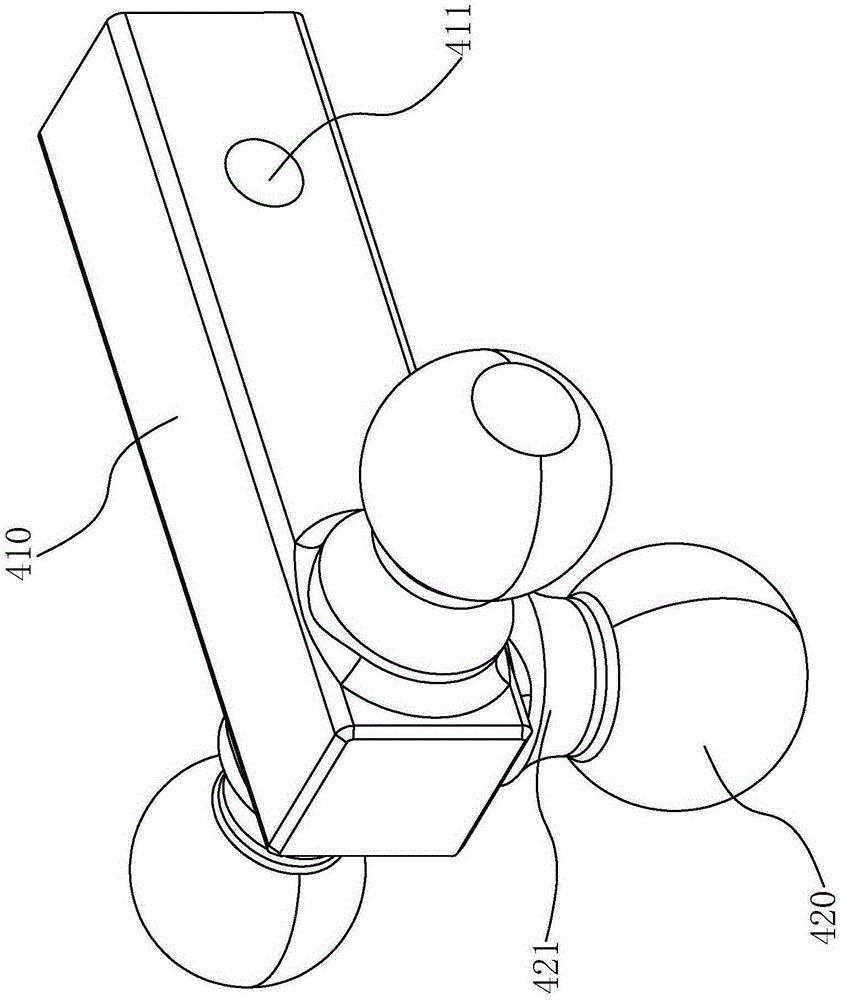

Adjustable trailer device

An adjustable, trailerable technology, applied in vehicle parts, transportation and packaging, traction connectors, etc., can solve the problems of high force loss, short service life of the trailer arm, and inability to adjust, and achieve less force loss and stress Concentrated, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] 100 parts of iron, 500 parts of manganese, 80 parts of silicon, 20 parts of carbon, 20 parts of titanium carbide, 20 parts of molybdenum, 10 parts of scandium, and 5 parts of lanthanum. Manganese ferroalloy is made through the following steps:

[0080] S1. Sieve the iron powder so that the particle size of the iron powder is between 200-400 mesh, and sieve the manganese powder so that the particle size of the manganese powder is between 300-400 mesh;

[0081] S2. Put iron powder, manganese powder and other components that meet the requirements into the ball mill for 2-3 hours and then let it stand for 1 hour;

[0082] S3, vacuum drying;

[0083] S4, sieving;

[0084] S5. Vacuum sintering at 500°C for 1 hour, vacuum sintering at 800°C for half an hour, vacuum sintering at 1100°C for half an hour, and vacuum sintering at 1400°C for 2 hours.

[0085] Iron and manganese are the main components of manganese-ferroalloys. If there is too little iron powder, the strength of t...

Embodiment 2

[0087] 300 parts of iron, 200 parts of manganese, 50 parts of silicon, 30 parts of carbon, 30 parts of titanium carbide, 10 parts of molybdenum, 5 parts of scandium, and 10 parts of lanthanum, are made into ferromanganese alloy through the following steps:

[0088] S1. Sieve the iron powder so that the particle size of the iron powder is between 200-400 mesh, and sieve the manganese powder so that the particle size of the manganese powder is between 300-400 mesh;

[0089] S2. Put iron powder, manganese powder and other components that meet the requirements into the ball mill for 2-3 hours and then let it stand for 1 hour;

[0090] S3, vacuum drying;

[0091] S4, sieving;

[0092] S5. Vacuum sintering at 700°C for 1 hour, 1000°C for half an hour, 1300°C for half an hour, and 1500°C for 2 hours.

Embodiment 3

[0094] 200 parts of iron, 400 parts of manganese, 60 parts of silicon, 25 parts of carbon, 25 parts of titanium carbide, 15 parts of molybdenum, 7 parts of scandium, and 8 parts of lanthanum. Manganese ferroalloy is made through the following steps:

[0095] S1. Sieve the iron powder so that the particle size of the iron powder is between 200-400 mesh, and sieve the manganese powder so that the particle size of the manganese powder is between 300-400 mesh;

[0096] S2. Put iron powder, manganese powder and other components that meet the requirements into the ball mill for 2-3 hours and then let it stand for 1 hour;

[0097] S3, vacuum drying;

[0098] S4, sieving;

[0099] S5. Vacuum sintering at 600°C for 1 hour, vacuum sintering at 900°C for half an hour, vacuum sintering at 1200°C for half an hour, and vacuum sintering at 1450°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com