A system and method for direct reuse of electroplating cleaning wastewater

A direct technology for cleaning wastewater, applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problems of complicated electroplating wastewater treatment process, low reuse rate of electroplating cleaning water, and high cost, and achieves a degree of automation. High efficiency, short response time and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: The electroplating cleaning water of a certain factory contains Cu 253mg / L, Ni 232mg / L, Cr 12mg / L, Zn 37mg / L, pH is 2.45, after being processed by the system of the present invention, it is reused in the cleaning process The water contains Cu 0.15mg / L, Ni0.03mg / L, Cr 0.19mg / L, Zn 0.09mg / L, pH is 7.11, and the content of heavy metals in reused water is stable up to the standard in Table 3 of GB21900-2008. After the implementation of the scheme of the present invention, 80% of the electroplating cleaning water of the factory is reused for production after treatment, and 20% is reused for other purposes in the factory area, and the total waste water discharge is reduced by more than 60%.

Embodiment 2

[0043] Example 2: The electroplating cleaning water of a certain factory contains Cu 184mg / L, Ni 202mg / L, Cr 74mg / L, Zn 78mg / L, pH is 2.73, after being processed by the system of the present invention, it is reused in the cleaning process The water contains 0.11mg / L Cu, 0.06mg / L Ni, 0.17mg / L Cr, and 0.13mg / L Zn, and the pH is 7.15. The content of heavy metals in reused water is stable up to the standard in Table 3 of GB21900-2008. After the implementation of this plan, 85% of the electroplating cleaning water in the factory will be reused for production after treatment, 5% will be used for dispensing in the water treatment workshop, and 10% will be used for floor washing in the workshop, road washing and greening, etc. The total wastewater discharge Reduced by more than 60%.

Embodiment 3

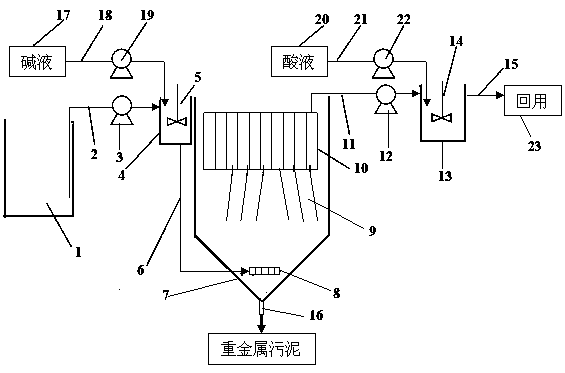

[0044] Example 3: Treatment of electroplating cleaning water in a factory, containing Cu 184mg / L, Ni 202mg / L, Cr 74mg / L, Zn 78mg / L, pH 2.68. After the electroplating cleaning water reaches a certain height, it enters the first regulating pool through the pipeline under the action of the raw water pump. The opening and closing of the raw water pump is automatically controlled by the liquid level in the raw water pool; Stirred by the first agitator, when the pH in the first adjustment pool reaches 9.8, the alkali adding pump stops adding alkali solution, and the opening and closing of the alkali adding pump is regulated by the pH automatic control device in the first adjustment pool; the submerged The membrane pore diameter in the membrane module is 50nm, and the operating pressure is -15kPa; when the pool liquid enters the second adjustment pool, the acid pump pumps 7% sulfuric acid or hydrochloric acid into the pool liquid and is stirred by the second agitator, and the second a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com