Red phosphor powder and preparation method thereof

A technology of red fluorescent powder and chemical structural formula, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as low luminous efficiency, low luminous efficiency of packaged LEDs, and restrictions on the industrial production and application of phosphors, and achieve luminescence Efficiency improvement, broad application prospects, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]The preparation method of the above-mentioned red fluorescent powder is a multi-step nitriding reaction in which the compound hydride is dehydrogenated and then nitrided, including the following steps in sequence:

[0036] 1) Press Ca 1-x-y Sr x Eu y L z Al 3 o δ N 4-δ The stoichiometric ratio weighs raw materials, grinds and mixes;

[0037] 2) Roasting the material obtained in step A at a high temperature in a reducing atmosphere at a temperature of 800 to 1300° C. and a firing time of 1 to 15 hours;

[0038] 3) Crushing and sieving the material obtained in step B to obtain a nitride red phosphor.

Embodiment 1

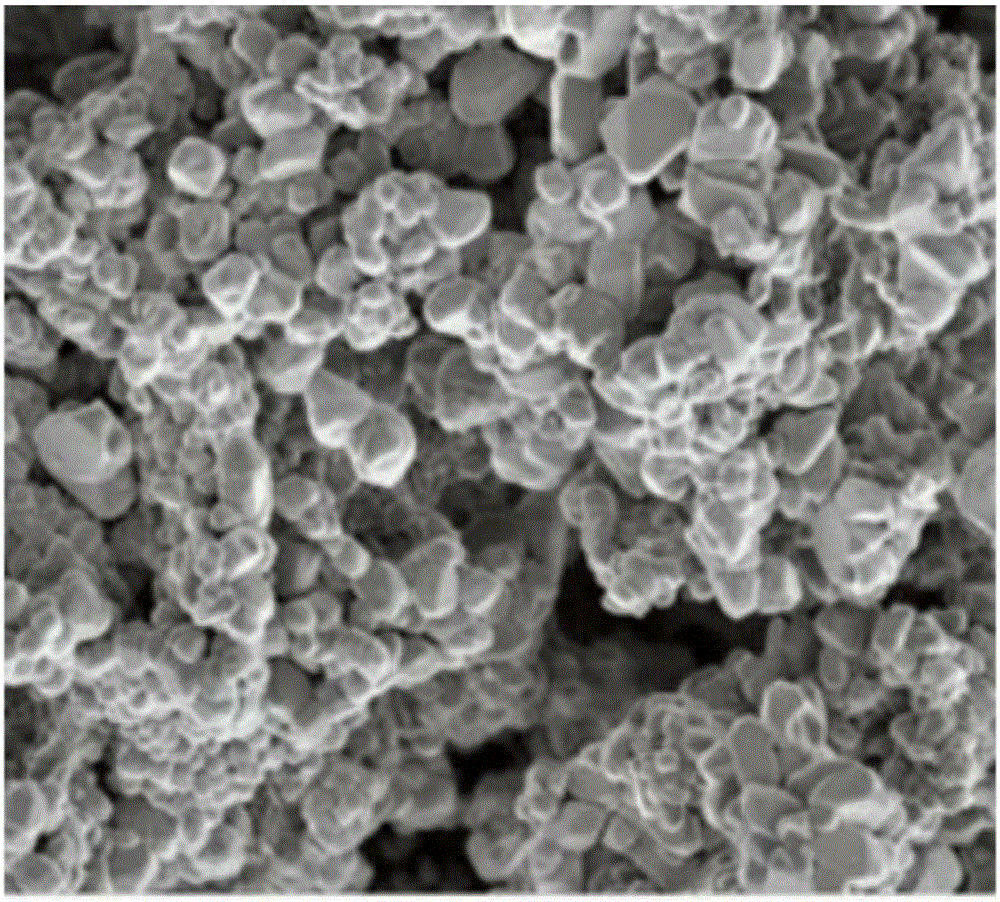

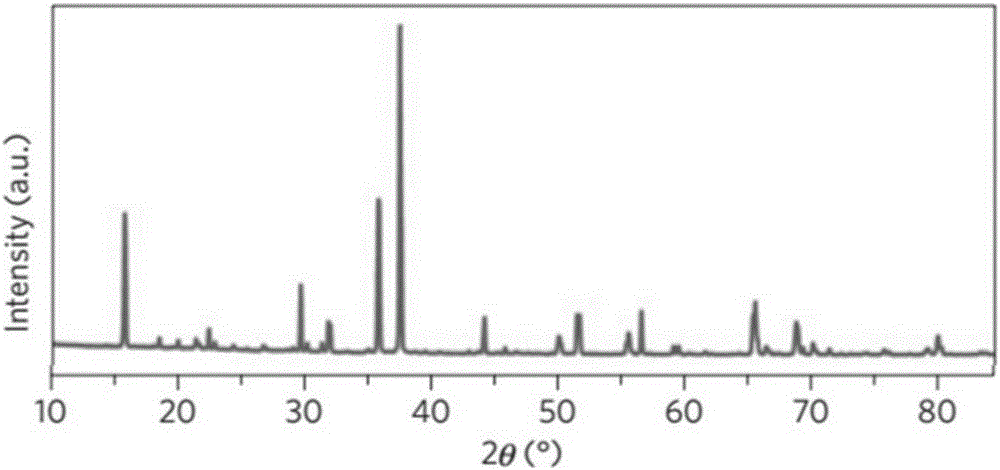

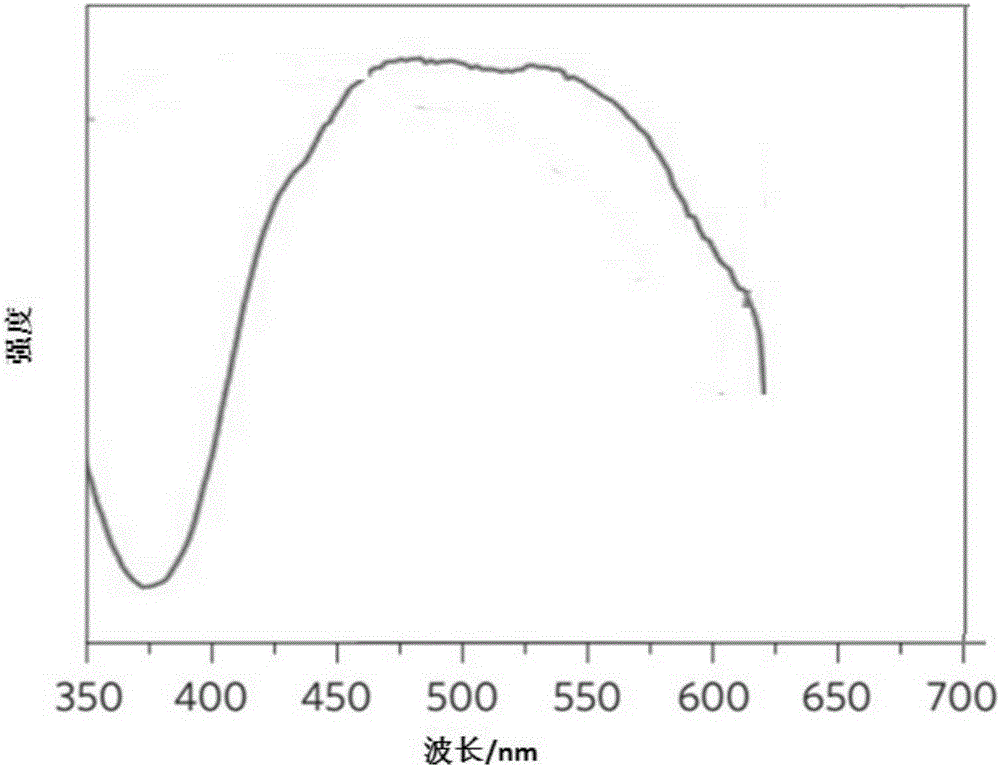

[0040] Weigh SrH 2 (4N)0.0996mol, LiAlH 4 (4N)0.1mol, AlN(4N)0.06667mol, Eu 2 o 3 (4N) 0.0002mol; put the above raw materials into the boron nitride crucible after mixing evenly in the glove box, and then quickly move it into the tube furnace, at 900 ℃ 0.1MpaN 2 Insulated in the atmosphere for 4 hours, the resulting product is crushed, washed to remove impurities, sieved, and dried to obtain the phosphor Sr 0.996 Eu 0.004 LiAl 3 o 0.006 N 3.96 . The SEM electron microscope picture, XRD collection of illustrative plates and absorption spectrogram of embodiment 1 are shown in figure 1 , figure 2 with image 3 .

Embodiment 2

[0042] Weigh CaH 2 (4N)0.0996mol, LiAlH 4 (4N)0.1mol, AlN(4N)0.06667mol, Eu 2 o 3 (4N) 0.0002mol; put the above raw materials into the boron nitride crucible after mixing evenly in the glove box, and then quickly move it into the tube furnace, at 900 ℃ 0.1MpaN 2 Insulated in the atmosphere for 4 hours, the resulting product is crushed, washed to remove impurities, sieved, and dried to obtain the phosphor Ca 0.996 Eu 0.004 LiAl 3 o 0.006 N 3.96 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com