A fire-resistant optical fiber composite medium-voltage cable and its manufacturing process

An optical fiber compounding and manufacturing process technology, applied in cable/conductor manufacturing, power cables including optical transmission components, coaxial cables, etc., can solve the problems of short normal power supply time, unfavorable escape and rescue, etc. The effect of improving the failure response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

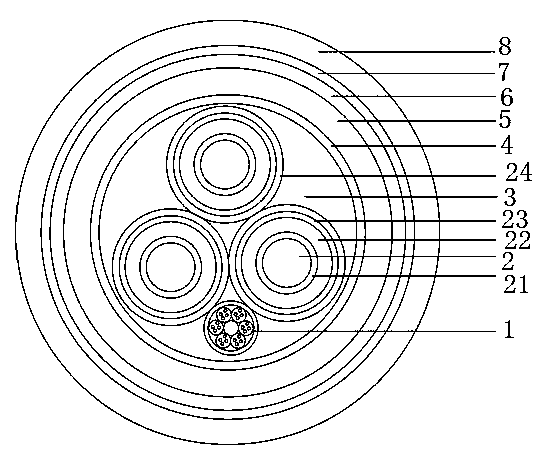

[0035] 1. Cable core

[0036] 1.1 Conductor stranding. The round compact copper conductor is adopted, and the conductor structure is dense. Under the same cross-sectional area of the conductor, the outer diameter of the conductor after compaction is reduced by about 10%, thereby reducing the outer diameter of the product and facilitating installation and laying.

[0037] 1.2 Three-layer co-extrusion. Conductor shielding layer, insulation layer, and insulation shielding layer adopt a three-layer co-extrusion production method, and the conductor shielding material, cross-linked polyethylene insulation material, and insulation shielding material are coated on the compact conductor at one time, and the extrusion production process is adopted , so that the three layers of materials are closely combined, while avoiding secondary pollution of insulating materials, ensuring the process quality of the product.

[0038] 1.3 Metal shielding. Overlap and wrap a layer of 0.1-0.12mm co...

Embodiment 2

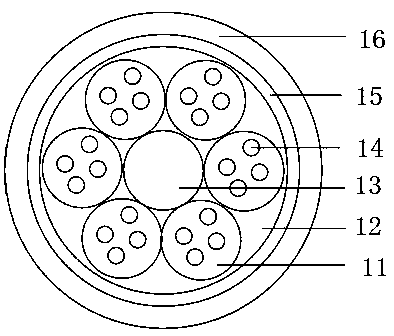

[0051] The manufacturing process includes the following steps: a. Making cable cores, compressing the circular copper conductors so that the outer diameter of the compacted conductors is reduced by 11%, and then extruding the insulating and shielding composite layer outside the compacted conductors , to make the cable core for later use; b. To make the optical cable unit, first make the optical fiber loose tube, which is provided with 4 core optical fibers, and surrounds 6 optical fiber loose tubes into a circle, and the center of the circle is provided with a strengthening member. Then the optical fiber loose tube is clad with a protective sleeve to make an optical cable unit, between the protective sleeve and the loose tube, between the loose tube and the reinforcement is filled with water-blocking yarn; c, product combination, the optical cable unit After being extruded together with the cable core, it is cabled, and the heat insulation layer, fire-resistant layer, oxygen ba...

Embodiment 3

[0056] A fire-resistant optical fiber composite medium-voltage cable, characterized in that: the composite medium-voltage cable is composed of an outer cladding and an inner core, and the inner core is formed by twisting a cable core and an optical cable unit; the optical cable unit is composed of a reinforced parts and loose tubes arranged around the reinforcing parts are twisted into cables; the cable core is composed of a conductor and an insulating and shielding composite layer extruded on the outside of the conductor; the outer cladding is composed of a heat insulation layer, a refractory layer, Oxygen barrier layer, impact-resistant layer and outer sheath layer are wrapped in sequence.

[0057] The optical cable unit is provided with a loose tube group consisting of 5 loose tubes. The center of the loose tube group is provided with a reinforcement made of resin fiber reinforced plastic FRP. The outer extruded protective sleeve of the loose tube group is , each loose tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com