Annealing method for photo-anode of perovskite solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of defective polycrystalline interiors and inability to effectively control the morphology of perovskite crystals, and achieve the goal of promoting morphology and reducing defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

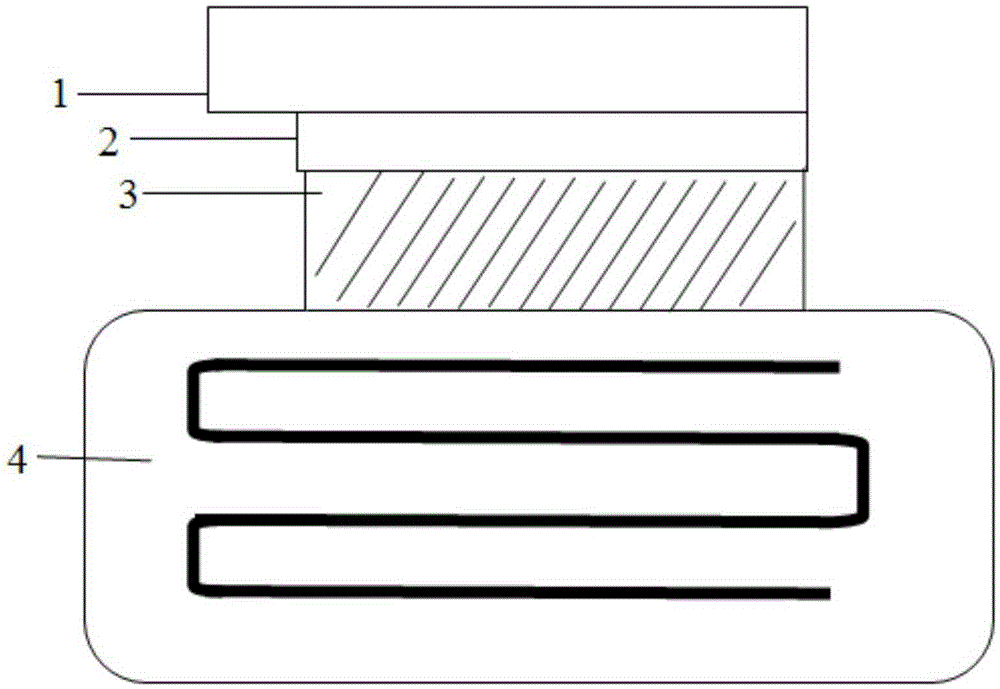

[0018] Embodiment 1: This embodiment is an annealing method for the anode of a perovskite solar cell, which is specifically carried out in the following steps:

[0019] When the photoanode of the perovskite solar cell is heated and annealed on the heating table, the perovskite light absorber layer of the photoanode of the perovskite solar cell directly contacts the heating table, and is annealed at an annealing temperature of 30°C to 170°C Treat for 5 minutes to 30 minutes; the photoanode of the perovskite solar cell is sequentially composed of a conductive glass layer, an electron transport layer and a perovskite light absorbing agent layer from top to bottom.

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the conductive glass is FTO conductive glass. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the conductive glass is ITO conductive glass. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spin coating thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com