Carbon fiber bundles and flame-resistant chemical fiber bundles

A carbon fiber bundle, single fiber technology, applied in the direction of fiber chemical characteristics, fiber processing, carbon compounds, etc., can solve the problems of difficult to apply technology and low processability, and achieve the effect of reducing equipment operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Using dimethyl sulfoxide as the solvent and 2,2'-azobisisobutyronitrile as the initiator, the copolymer of 99.5 mol% of acrylonitrile and 0.5 mol% of itaconic acid was processed by solution polymerization. Polymerize to produce a polyacrylonitrile copolymer with a weight average molecular weight of 400,000 and an Mz / Mw of 2.1. Ammonia gas was blown into the obtained polyacrylonitrile-based polymer until the pH became 8.5, and the concentration of the polymer was adjusted to 19% by mass to obtain a spinning solution. The resulting spinning solution was used in the dry-wet spinning method (that is, at 40°C, the spinneret A was used to temporarily discharge the resulting spinning solution into the air, and after it passed through a space of about 5 mm, it was introduced to In a coagulation bath formed from a 79% dimethyl sulfoxide aqueous solution at 5°C, coagulation filaments were made. After washing the coagulated yarn with water by a conventional method, it was stretche...

Embodiment 2

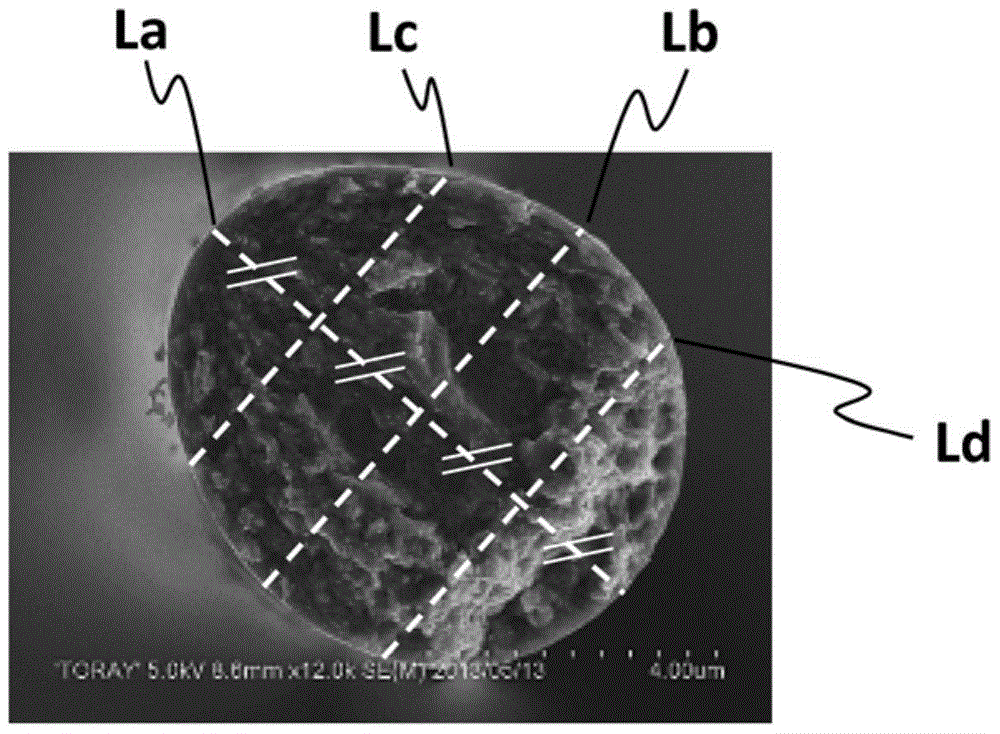

[0120] The spinneret B was used to obtain a polyacrylonitrile-based precursor fiber bundle in the same manner as in Example 1, except that the space through which the spinning solution was discharged from the nozzle was about 4 mm. There is no particular problem with the passability of the silk making process. In the same manner as in Example 1, a carbon fiber bundle was obtained. The evaluation results are shown in Table 1. The SEM photograph of the cross section is as Image 6 Shown. In addition, the cross-sectional shape of the flame-resistant fiber bundle was also evaluated. The evaluation results are shown in Table 2.

Embodiment 3

[0122] Except that the single fiber fineness of the precursor fiber bundle was 0.7 dtex, the same procedure as in Example 1 was carried out to obtain a polyacrylonitrile-based precursor fiber bundle. There is no particular problem with the passability of the silk making process. The carbon fiber bundle was obtained in the same manner as in Example 1, except that the maximum temperature of the carbonization treatment was 1500°C and the tension was 3.5 mN / dtex. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com