Argy wormwood leaf fine dried noodles and preparation method thereof

A technique for dried noodles and argyi leaves, applied in the field of dried argyi leaves and its preparation, can solve the problems of easy mutual adhesion of noodles, low toughness and viscosity, gelatinization and fracture, etc., so as to reduce cooking loss, ease internal stress, and improve viscoelasticity. and extension effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

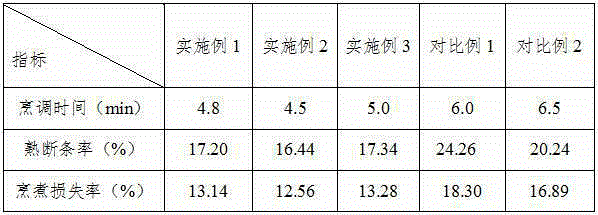

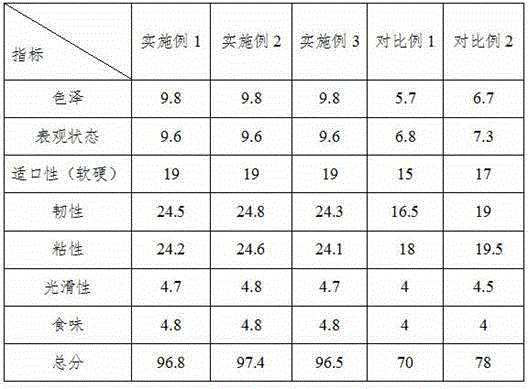

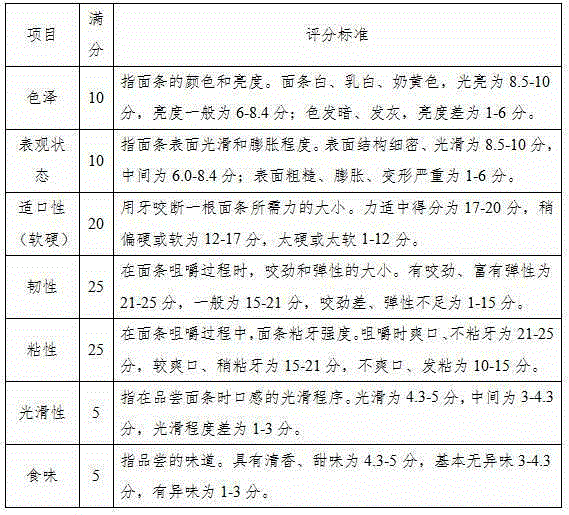

Examples

Embodiment 1

[0033] Embodiment 1, A kind of Artemisia vermicelli

[0034] Described mugwort vermicelli comprises following preparation raw material and parts by weight thereof:

[0035] 20 parts of mugwort leaf powder, 10 parts of tamarind powder, 8 parts of cistanche powder, 6 parts of chickpea powder, 65 parts of wheat flour, 0.5 part of sodium alginate, 0.1 part of potassium carbonate and 0.1 part of edible salt.

[0036] Preparation:

[0037] S1 Mix the above-mentioned mugwort leaf powder, tamarind powder, cistanche powder and chickpea powder through a 70-mesh fine sieve to obtain a mixed fine powder;

[0038] S2 put the above-mentioned wheat flour, sodium alginate, potassium carbonate, edible salt and the mixed fine powder obtained in step S1 into the dough mixer, then add 28% water of the total amount of the above-mentioned mixed material, and stir evenly;

[0039] S3 compresses the noodle block obtained in step S2 by means of composite calendering, wherein the thickness of the in...

Embodiment 2

[0044] Embodiment 2, A kind of Artemisia vermicelli

[0045] Described mugwort vermicelli comprises following preparation raw material and parts by weight thereof:

[0046] 30 parts of mugwort leaf powder, 15 parts of tamarind powder, 10 parts of cistanche powder, 8 parts of chickpea powder, 78 parts of wheat flour, 1 part of sodium alginate, 0.5 part of potassium carbonate and 0.1 part of edible salt.

[0047] Preparation:

[0048] S1 Mix the above-mentioned mugwort leaf powder, tamarind powder, cistanche powder and chickpea powder through an 80-mesh fine sieve to obtain a mixed fine powder;

[0049] S2 put the above-mentioned wheat flour, sodium alginate, potassium carbonate, edible salt and the mixed fine powder obtained in step S1 into the dough mixer, then add 35% water of the total amount of the above-mentioned mixed material, and stir evenly;

[0050] S3 compresses the noodle block obtained in step S2 by compound calendering, wherein the thickness of the initial pre...

Embodiment 3

[0055] Embodiment 3, A kind of Artemisia vermicelli

[0056] Described mugwort vermicelli comprises following preparation raw material and parts by weight thereof:

[0057] 50 parts of mugwort leaf powder, 20 parts of tamarind powder, 12 parts of cistanche powder, 10 parts of chickpea powder, 85 parts of wheat flour, 3 parts of sodium alginate, 2 parts of potassium carbonate and 1 part of edible salt.

[0058] Preparation:

[0059] S1 Mix the above-mentioned mugwort leaf powder, tamarind powder, cistanche powder and chickpea powder through a 100-mesh fine sieve to obtain a mixed fine powder;

[0060] S2 put the above-mentioned wheat flour, sodium alginate, potassium carbonate, edible salt and the mixed fine powder obtained in step S1 into the dough mixer, then add 38% water of the total amount of the above-mentioned mixed material, and stir evenly;

[0061] S3 compresses the noodle block obtained in step S2 by means of compound calendering, wherein the thickness of the ini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com