Fracturing flowback fluid biological processing method based on BESI technology

A fracturing flowback fluid and biological treatment technology, applied in biological treatment devices, biological water/sewage treatment, mining wastewater treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

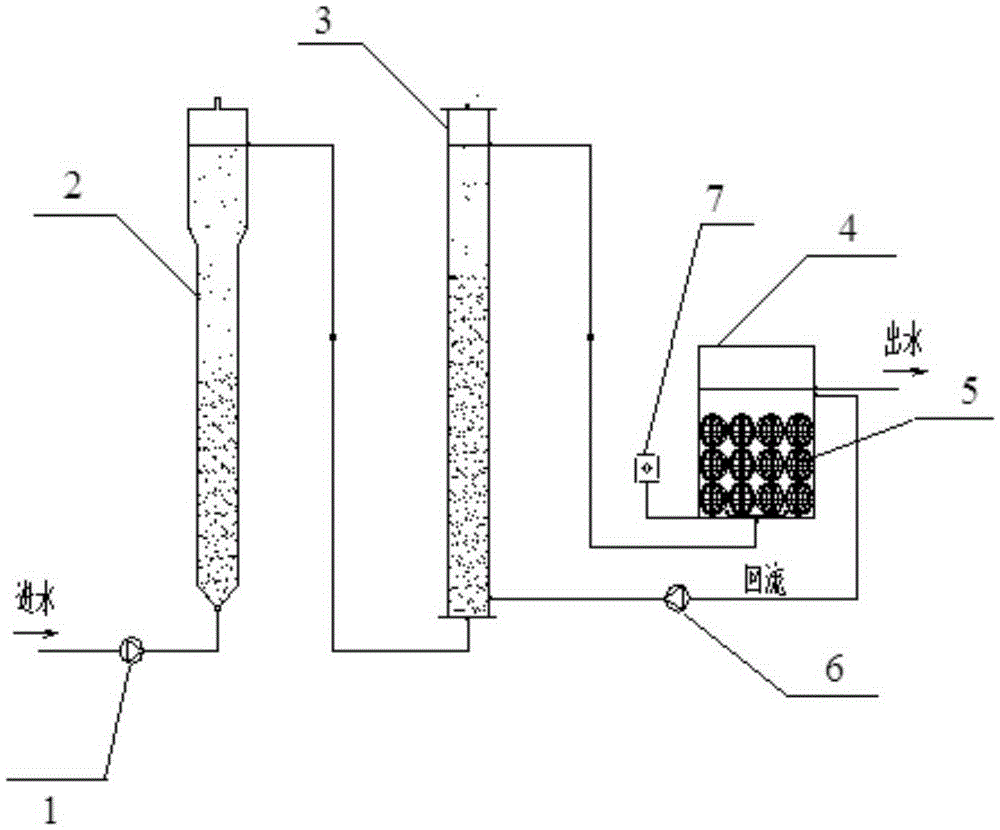

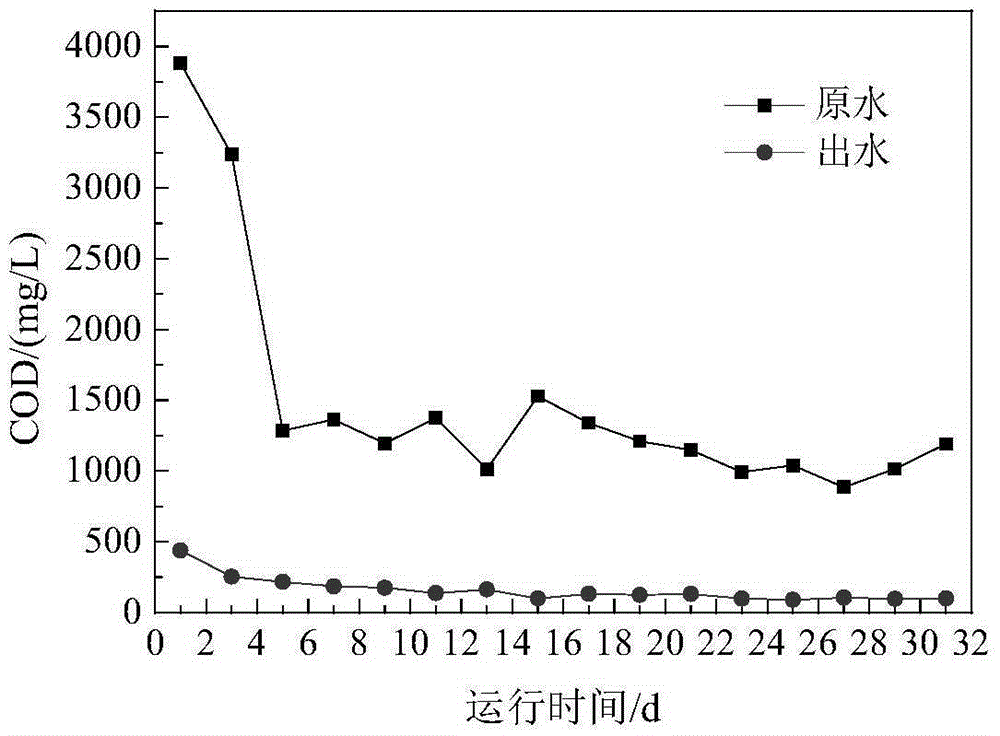

[0020] Specific embodiment one: a kind of fracturing flowback fluid biological treatment method based on BESI technology comprises the following steps:

[0021] Step 1: The fracturing flowback fluid enters the anaerobic reaction device (2) through the sewage inlet pump (1) through the bottom water inlet of the anaerobic reaction device (2) for treatment, and the HRT is 20 to 28 hours, and the HRT is water conservancy dwell time;

[0022] Step 2: The fracturing flowback fluid treated in step 1 flows out through the water outlet on the top side wall of the anaerobic reaction device (2), and enters the facultative anaerobic reaction device ( 3), HRT is 20-28 hours;

[0023] Step 3: The fracturing flowback fluid treated in step 2 flows out through the top side wall water outlet of the facultative anaerobic reaction device (3), and enters the aerobic reaction device (4) through the bottom water inlet of the aerobic reaction device (4) ), HRT is 44-52 hours;

[0024] Step 4: The ...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the anaerobic reaction device (2) is specifically:

[0029] The anaerobic reaction device (2) adopts UASB, ABR, IC or SBR anaerobic reactor, the filler added in the anaerobic reaction device (2) is a suspended filler, and the volume of the added suspended filler is the volume of the anaerobic reaction device (2). 30~50%; the acclimation condition of described suspended packing: the sludge inoculated is the sludge of the anaerobic biological treatment section of Daqing Oilfield Dongfeng Sewage Treatment Plant, and the inoculum amount of sludge is 18~18% of the volume of the anaerobic reaction device (2). 20%, the domestication period is 12-18 days;

[0030] The suspended filler is black polyurethane filler with a size of 4×4×4cm.

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment is different from one of the specific embodiments one to two: the facultative anaerobic reaction device (3) is specifically:

[0032] The facultative anaerobic reaction device (3) adopts UASB, ABR, IC or SBR anaerobic reactor, and the oxygen in the facultative anaerobic reaction device (2) is obtained by reflux from the aerobic reaction device; The filler added in the reaction device (3) is an elastic filler, and the volume of the added elastic filler is 30% to 40% of the volume of the facultative anaerobic reaction device (3); the domestication conditions of the elastic filler: the inoculated sludge is Daqing Oilfield For the sludge in the anaerobic biological treatment section of Dongfeng Sewage Treatment Plant, the inoculum amount of the sludge is 18-20% of the volume of the anaerobic reaction device (2); the domestication period is 12-18 days;

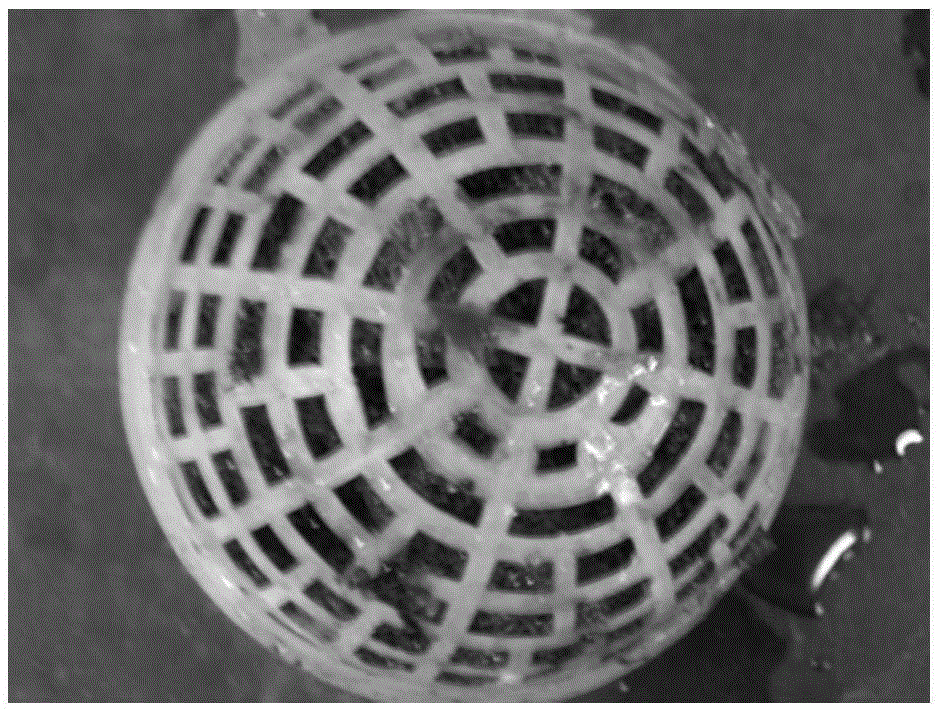

[0033] The elastic filler is made of PVC with a diameter of 10 cm, and the elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com