High-heat-conductive rubber composition, preparation method thereof and tyre

A rubber composition and high thermal conductivity technology, applied in the field of materials, can solve problems such as difficulty in obtaining single-layer graphene, achieve the effects of improving thermal conductivity, improving durability, and shortening vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Preparation of the rubber composition:

[0048] The rubber composition with following composition is prepared by the method of mixing, and described mixing comprises:

[0049] (1) Master refining:

[0050] The master batching is carried out in X(S)M-1.6×(0~180) internal mixer, the initial temperature is 50°C, the speed is 70 rpm, and the pressure is 7bar. The order of feeding is: rubber is added initially, then white carbon black, carbon black, carbon nanotubes, graphene, coupling agent, anti-aging agent, zinc oxide, microcrystalline wax, stearic acid and plasticizer are added after 30s, and finally in Glue removal at 155C.

[0051] (2) Final refinement:

[0052] The final refining is carried out in the X(S)M-1.6×(0~180) type internal mixer, the feeding sequence: masterbatch at the beginning, accelerator accelerator and sulfur after 20s, glue discharge after 180s.

[0053] Raw materials and equipment:

[0054] Natural rubber (TSR20), white carbon black (NewsilHD165MP...

Embodiment 1

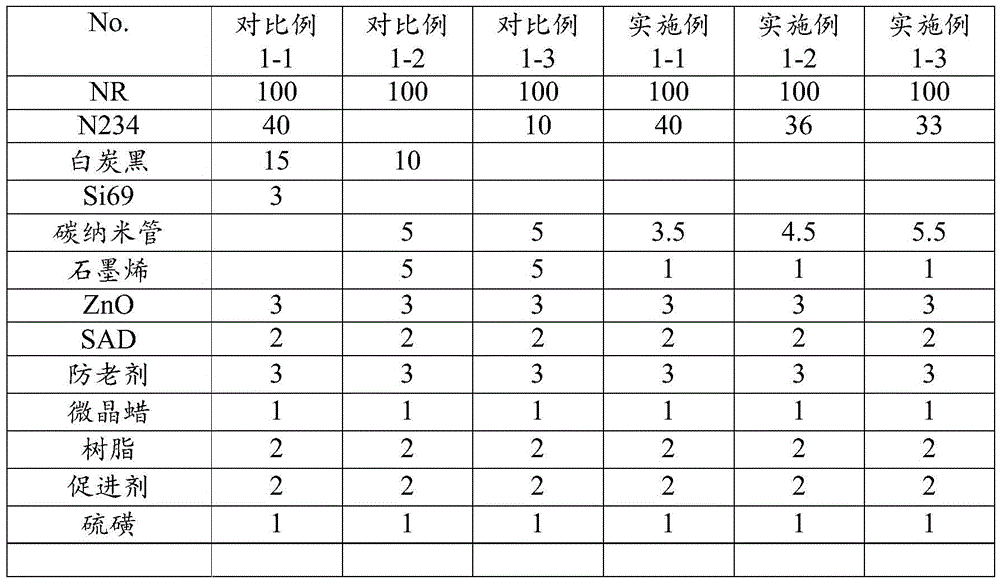

[0072] In Example 1, natural rubber was used as the rubber system, and the contribution of different amounts of carbon nanotubes, graphene, and fillers (carbon black, silica) to the thermal conductivity of the system was adjusted through formulation. The diameter of carbon nanotubes used is 5-20nm, the length is 3-50μm, and the specific surface area is 200-300m 2 / g; graphene specific surface area 40 ~ 100m 2 / g, purity>97wt%, thickness<30nm.

[0073] Table 1: Properties of Example 1 Laboratory Tests.

[0074]

[0075]

[0076] It can be seen from Table 1 above:

[0077] 1) Comparative example 1-1 is the formula in the actual production process of tires. Only by maintaining a relatively high carbon black and silica content can the normal production and use requirements be met. In Comparative example 1-2 and Comparative example 1-3 Although adding a large amount of carbon nanotubes and graphene can also maintain the thermal conductivity of the vulcanized rubber, it wil...

Embodiment 2

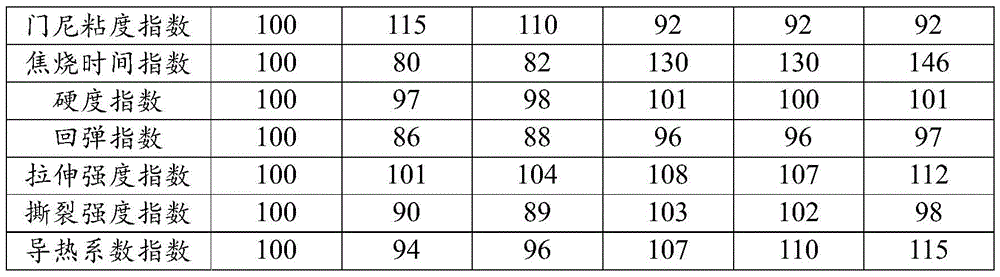

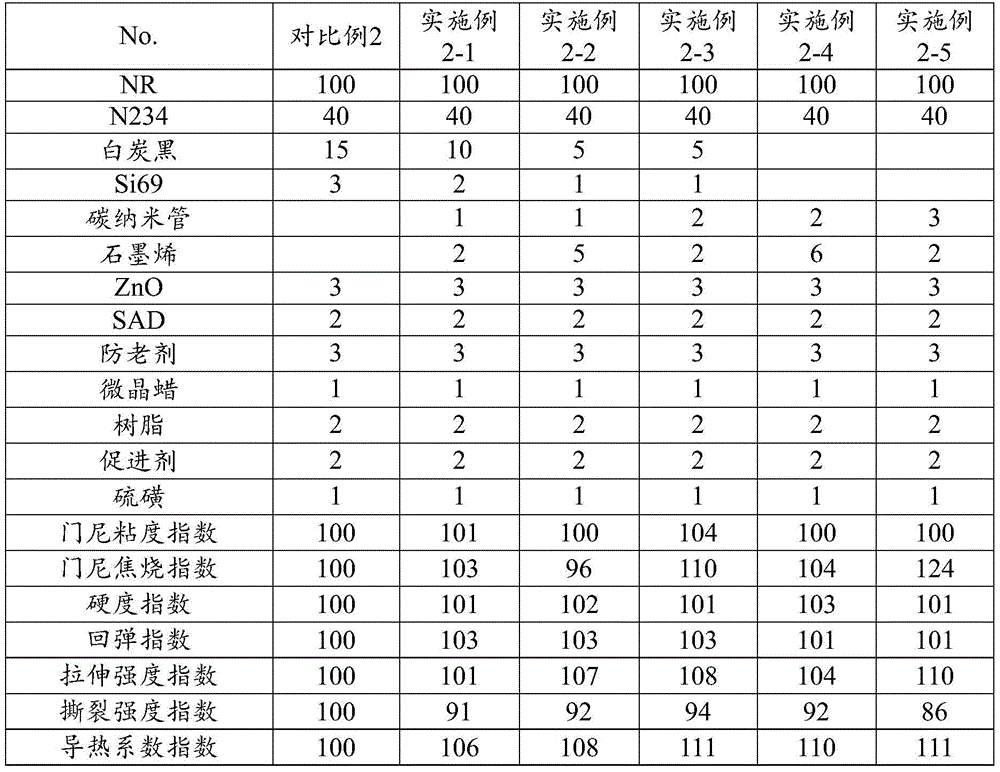

[0080] In embodiment 2, natural rubber is adopted as the rubber system, carbon nanotubes and graphene are added in different amounts through formula adjustment, while maintaining a higher filling amount of carbon black (consumption is 40 parts by weight) to verify carbon nanotubes and graphite The influence of compound use of ethylene on the thermal conductivity of the system. The specific implementation scheme is shown in Table 2.

[0081] Table 2: Performance of Example 2 Laboratory Tests

[0082]

[0083] It can be found from Table 2 that after adding carbon nanotubes and graphene, the Mooney viscosity, scorch time and hardness will basically remain unchanged, while the tensile strength and resilience performance will be significantly improved, but the tear strength will be reduced. It is found from the data that the thermal conductivity of carbon nanotubes and graphene is significantly improved after being combined and shared, which can be increased by more than 10%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com