Polycarbonate composite and preparation method of same

A polycarbonate and composition technology, applied in the field of engineering plastics, can solve the problems of reducing material toughness, poor dimensional stability, affecting dimensional stability and processing fluidity, etc. The effect of functionality and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9 and

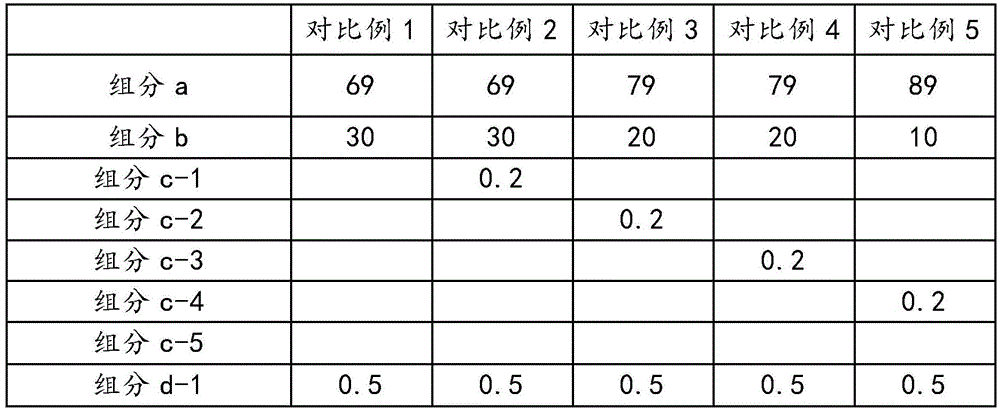

[0051] Embodiment 1-9 and comparative example 1-7 follow the steps below, to prepare polycarbonate composition:

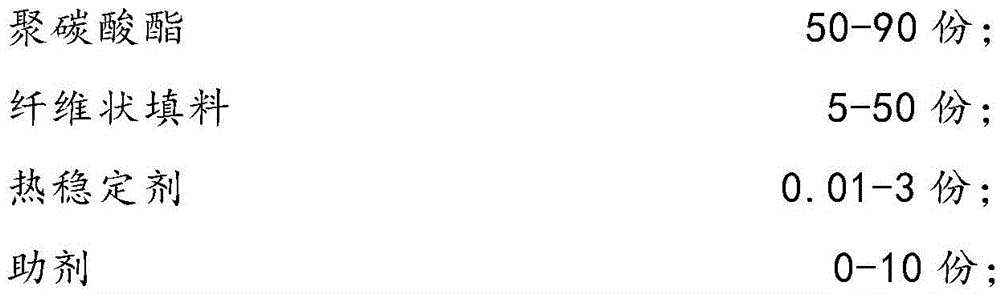

[0052] Step 1: According to the following components: polycarbonate, fibrous filler, heat stabilizer and additives;

[0053] Step 2: Dry polycarbonate, fibrous fillers and additives at a drying temperature of 120-130°C for 4-6 hours;

[0054] Step 3: Add the dried polycarbonate and additives into the high-speed mixer, and then add a heat stabilizer for mixing. The mixing temperature is 30-50°C and the mixing time is 5-15 minutes to obtain a mixture;

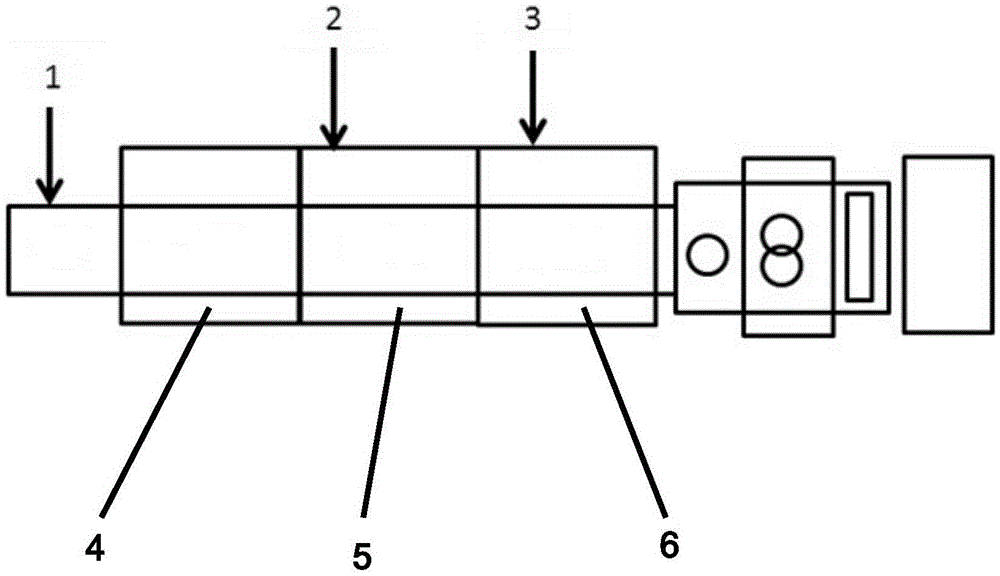

[0055] Step 4: Feed the mixture in step 3 into the first feeding port 1, add glass fiber to the first feeding port 1, the second feeding port 2 or the third feeding port 3, the number of glass fibers added Each example and comparative example is different. The temperature of the twin-screw extruder is controlled at 200-280°C, and at least one vacuum is installed. The vacuum can be located at the end of the feeding s...

Embodiment 1-9

[0071] The following table is the proportioning of the raw materials used in Examples 1-9, and related test results:

[0072]

[0073] In embodiment 1-9, based on the total weight of glass fibers, glass fibers accounting for 60% of the total weight of glass fibers are added from the first feeding port 1, and the time of staying in the first screw barrel 4 is 20-30s ; Based on the glass fiber gross weight, the glass fiber that accounts for 40% of the glass fiber gross weight is from the second feeding port 2, and the time to stay in the second screw barrel 5 is 8-15s; obtain embodiment 1-9 Compositions of Component I comprising specific glass fiber length distributions and weight ratios.

[0074] The polycarbonate composition that embodiment 1-9 finally obtains, according to test standard is that the density that ISO1133 records is 1.22g / cm 3 -1.80g / cm 3 ; At 300°C, the shear viscosity measured under the condition of a shear rate of 1000s-1 is 110Pa·s-350Pa·s.

[0075] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com