Fuel oil additive and preparation method therefor

A technology of additives and fuel oil, which is applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of inability to protect the engine, lower fuel efficiency, incomplete fuel combustion, etc., to improve combustion efficiency, increase engine power, and complete combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

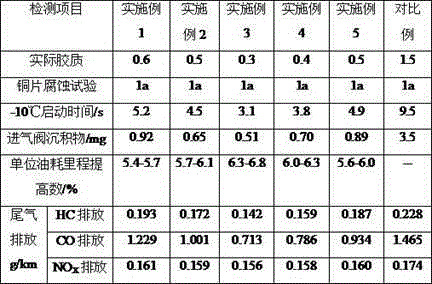

Examples

Embodiment 1

[0026] A fuel additive, which is composed of the following raw materials in parts by weight: 12 parts of polyisobutenylamine, 5 parts of urotropine, 40 parts of lauryl isopropanolamine, 5 parts of cosolvent, 0.5 parts of sucrose acetate isobutyrate 0.8 part, 0.8 part of ethylene glycol distearate, 10 parts of combustion enhancer;

[0027] The co-solvent is obtained by mixing Tween 60 and hydroxyethyl cellulose in a weight ratio of 1:1;

[0028] The combustion enhancer is obtained by mixing raw tung oil, 3-cyanopyridine and allyl alcohol in a weight ratio of 1:1.5:0.3.

[0029] A preparation method of a fuel additive is prepared by the following steps:

[0030] 1) Take polyisobutenylamine, sucrose acetate isobutyrate and combustion accelerant in parts by weight, put them into a reaction kettle and stir for 2 hours to obtain material 1;

[0031] 2) Add co-solvent to material 1, continue to stir for 1 hour, and obtain material 2;

[0032] 3) Add urotropine, lauryl isopropanola...

Embodiment 2

[0034] A fuel additive, which is composed of the following raw materials in parts by weight: 10 parts of polyisobutenylamine, 6 parts of urotropine, 35 parts of lauryl isopropanolamine, 8 parts of cosolvent, 0.7 parts of sucrose acetate isobutyrate 0.9 parts, 0.9 parts of ethylene glycol distearate, 15 parts of combustion enhancer.

[0035] The co-solvent is obtained by mixing Tween 60 and hydroxyethyl cellulose in a weight ratio of 1:1.2;

[0036] The combustion enhancer is obtained by mixing raw tung oil, 3-cyanopyridine and allyl alcohol in a weight ratio of 1:1.3:0.4.

[0037] A preparation method of a fuel additive is prepared by the following steps:

[0038] 1) Take polyisobutenylamine, sucrose acetate isobutyrate and combustion accelerant according to parts by weight, put them into a reaction kettle and stir for 1.5 hours to obtain material 1;

[0039] 2) Add co-solvent to material 1, continue to stir for 1.5h to obtain material 2;

[0040] 3) Add urotropine, lauryl ...

Embodiment 3

[0042] A fuel additive, which is composed of the following raw materials in parts by weight: 9 parts of polyisobutenylamine, 8 parts of urotropine, 30 parts of lauryl isopropanolamine, 10 parts of cosolvent, 0.8 parts of sucrose acetate isobutyrate 0.9 parts, 0.9 parts of ethylene glycol distearate, 18 parts of combustion enhancer.

[0043] The co-solvent is obtained by mixing Tween 60 and hydroxyethyl cellulose in a weight ratio of 1:1.3;

[0044] The combustion enhancer is obtained by mixing raw tung oil, 3-cyanopyridine and allyl alcohol in a weight ratio of 1:1:0.5.

[0045] A preparation method of a fuel additive is prepared by the following steps:

[0046] 1) Take polyisobutenylamine, sucrose acetate isobutyrate and combustion accelerant according to parts by weight, put them into a reaction kettle and stir for 1.5 hours to obtain material 1;

[0047] 2) Add co-solvent to material 1, continue to stir for 1.5h to obtain material 2;

[0048] 3) Add urotropine, lauryl is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com