Preparation method for kitasamycin industrial production strains

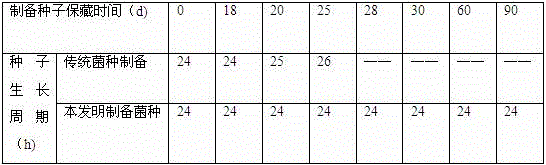

A technology of kitasomycin and strains, applied in the field of preparation of strains for industrialized production of kitasamycin, which can solve the problems of unstable seed growth cycle, frequent batch replacement, unstable fermentation level of kitasamycin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method for industrialized production of kitasarmycin, comprising the steps of:

[0019] a) Single colony preparation: Unseal the initial kitasarmycin strain tube, add 0.5mL sterile normal saline, shake evenly to make a bacterial suspension, dip in the inoculation needle, draw a line on the separation plate, and place it at a constant temperature of 28°C Plate culture in the room for 9 days to obtain a single colony;

[0020] b) Preparation of slant spores: take the single colony prepared in step a) and evenly spread it on the slant, and cultivate it in a constant temperature room at 28°C for 9 days;

[0021] c) Preparation of freeze-dried strain tubes: take the slant spores prepared in step b), scrape off the slant spores with an inoculation loop under sterile conditions, prepare freeze-dried strain tubes by freeze-drying method, label them, and write Date, batch number, stored in a refrigerator at 4°C;

[0022] d) Preparation of milk freezing tube: Unse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com