One bath process dyeing process of polyester cotton dispersing dye and reactive dye

A technology of reactive dyes and disperse dyes, used in dyeing methods, textiles and papermaking, dry cleaning fiber products, etc., can solve the problems of hindering the dyeing of polyester-cotton blended fabrics, unstable color fixing, cotton yarn color difference, etc. Fastness level, high alkali resistance, effect of color stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

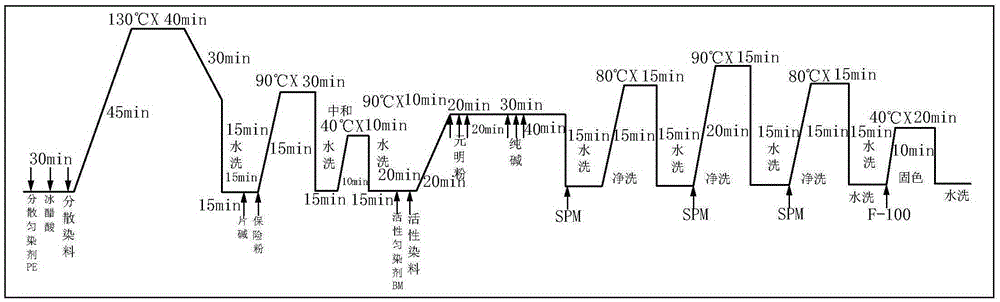

[0038] One-bath dyeing of light-colored single-color disperse / reactive dyes, fabric specifications: polyester-cotton blended fabric No. 58 / 9 32*32 / 120*70 and polyester-cotton blended fabric No. 63 32*32 / 120*70.

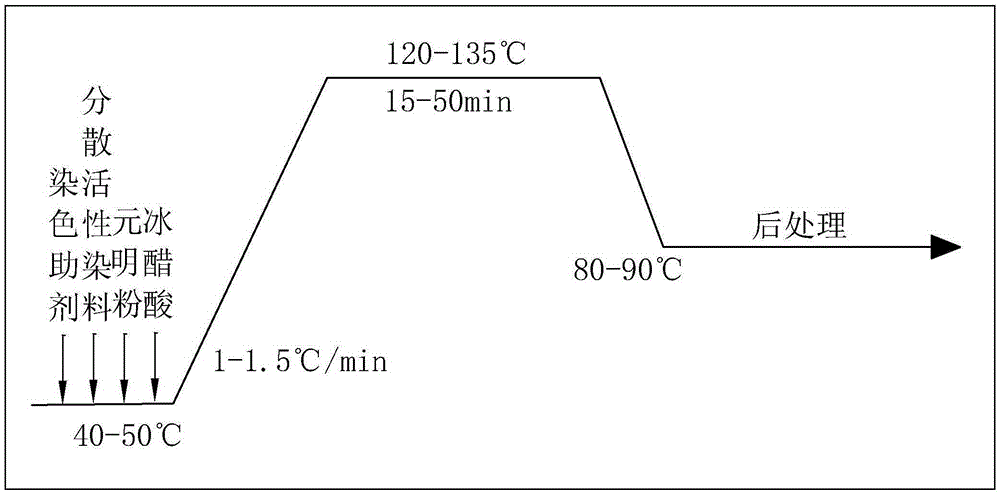

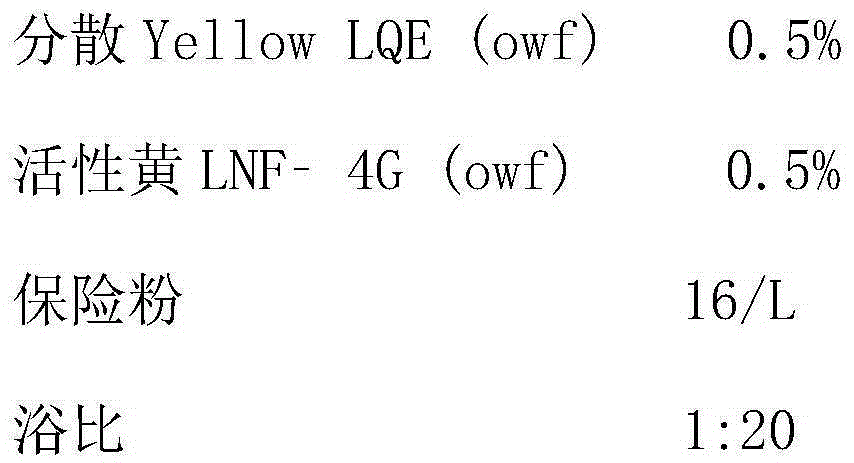

[0039] S1. Immerse the greige cloth in a 40°C coagulation bath, add dyeing auxiliaries, disperse / reactive dyes and sodium sulfate in sequence, and the bath contains:

[0040]

[0041] Then add acetic acid to adjust the pH to 4-6 (adjusted to 5.7 in this example), and then raise the temperature to 130°C at a rate of 1-1.5°C / min for about 1h20min, keep it for 30 minutes and then rise to 80°C.

[0042] S2. Pre-dry the cloth with infrared pre-drying and oven pre-drying, the pre-drying temperature is 100°C, and the time is 30s.

[0043] S3. Roasting to fix the color, the roasting temperature is 210°C, and the roasting time is 100s.

[0044] S4. Soaping, use NP-10 as the soaping agent, the dosage is 2g / L, add hydrosulfite 2g / L, soap wash at 95°C for 15 minutes, and then...

Embodiment 2

[0048] One-bath dyeing of light-colored polydisperse / reactive dyes, fabric specifications: polyester-cotton blended fabric No. 58 / 9 32*32 / 120*70 and polyester-cotton blended fabric No. 63 32*32 / 120*70.

[0049] S1. Immerse the greige cloth in a 40°C coagulation bath, add dyeing auxiliaries, disperse / reactive dyes and sodium sulfate in sequence, and the bath contains:

[0050]

[0051] Then add acetic acid to adjust the pH to 4-6 (adjusted to 5.7 in this example), and then raise the temperature to 130°C at a rate of 1-1.5°C / min for about 1h20min, keep it for 30 minutes and then rise to 80°C.

[0052] S2. Pre-dry the cloth with infrared pre-drying and oven pre-drying, the pre-drying temperature is 100°C, and the time is 30s.

[0053] S3. Roasting to fix the color, the roasting temperature is 210°C, and the roasting time is 100s.

[0054] S4. Soaping, use NP-10 as the soaping agent, the dosage is 2g / L, add hydrosulfite 2g / L, soap wash at 95°C for 15 minutes, and then wash wit...

Embodiment 3

[0058] Single-color disperse / reactive dye dyeing in one bath of neutral color, fabric specifications: polyester-cotton blended fabric No. 58 / 9 32*32 / 120*70 and polyester-cotton blended fabric No. 63 32*32 / 120*70.

[0059] S1. Immerse the greige cloth in a 40°C coagulation bath, add dyeing auxiliaries, disperse / reactive dyes and sodium sulfate in sequence, and the bath contains:

[0060]

[0061] Then add acetic acid to adjust the pH to 4~6 (adjusted to 5.2 in this example), and then raise the temperature to 130°C at a rate of 1~1.5°C / min.

[0062] S2. Pre-dry the cloth with infrared pre-drying and oven pre-drying, the pre-drying temperature is 100°C, and the time is 30s.

[0063] S3. Roasting to fix the color, the roasting temperature is 210°C, and the roasting time is 100s.

[0064] S4, adding a quaternary ammonium salt color fixing agent for color fixing treatment.

[0065] S4. Soaping, use NP-10 as the soaping agent, the dosage is 2g / L, add hydrosulfite 2g / L, soap wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com