High-precision temperature measurement system based on resistance value comparison method

A comparative and high-precision technology, applied in the direction of thermometers, thermometers, measuring devices, etc., which are directly sensitive to heat-sensitive electrical/magnetic components, can solve the problem that the temperature measurement accuracy cannot be very high, and reduce the use of restrictions, high Accuracy, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

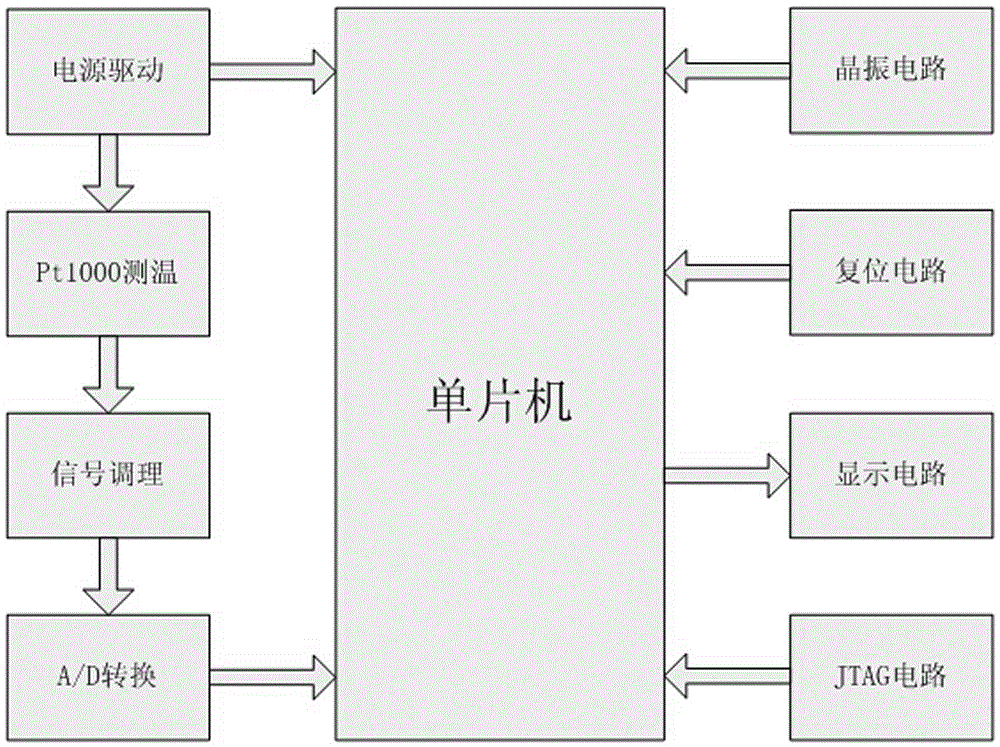

[0017] Such as figure 1 , figure 2 As shown, a high-precision temperature measurement system based on the resistance value comparison method is composed of a temperature signal acquisition element, an analog-to-digital converter, a control unit, and a display device; the temperature signal acquisition element adopts a Pt1000 platinum thermal resistance; The digital converter adopts AD7712; the control unit adopts MSP430F149 single-chip microcomputer; the display device adopts LCD1602 liquid crystal; the temperature signal acquisition element is connected to the analog-digital converter, and the analog-digital converter is connected to the control unit; device.

[0018] The Pt1000 thermal resistance is connected in series with a reference resistance of known resistance, powered by a 5V power supply.

[0019] The thermal resistor Pt1000 senses the temperature change and generates a corresponding voltage change, and the voltage signal is converted into a digital signal...

Embodiment 2

[0024] Such as figure 1 As shown, what the present invention designs is the temperature measuring circuit with Pt1000 platinum thermal resistance as temperature signal acquisition element, AD7712 as analog-to-digital converter, MSP430F149 single-chip microcomputer as control unit, LCD1602 liquid crystal as display device; Pt1000 thermal resistance is used in the circuit It is connected in series with a reference resistor of known resistance and powered by a 5V power supply; the thermal resistor Pt1000 will sense the temperature change and generate a corresponding voltage change. The system reads; the single-chip microcomputer system will identify, process and calibrate the read digital signal, and convert it into a digital signal corresponding to the temperature, and transmit it to the liquid crystal display, and the display will output the temperature value; due to the different functions of the selected chips, The temperature measurement circuit can be divided into variou...

Embodiment 3

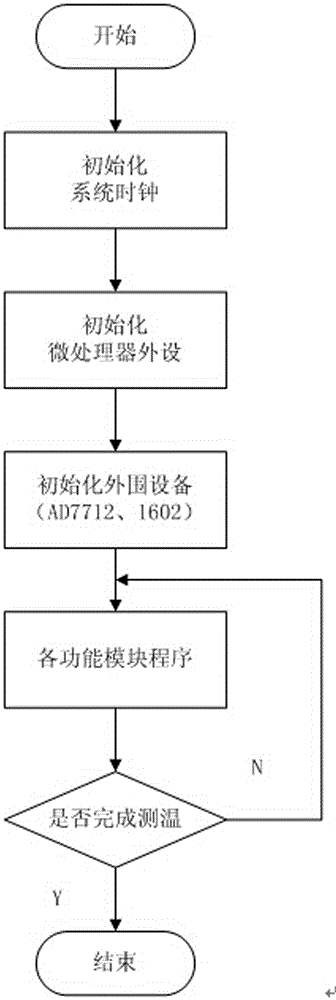

[0026] Such as figure 2 Shown, the main function of software among the present invention is: the integrated A / D converter AD7712 converts the physical signal measured by the temperature sensor Pt100 into a digital signal by A / D, and then sends it into the single-chip microcomputer MSP430F149 Carry out calibration, and finally display the calibrated digital signal on the liquid crystal display 1602; apply the idea of modular programming, divide the system software into several parts such as main program, data acquisition program, data conversion program and data display program, so that it can realize The function of the system; the main program of the system is the most important part of the entire system software, it is used to manage all the functions that can be realized by the temperature measurement circuit; the main program is the main body of the system software, it can organically connect other subroutine modules Together, they form a whole, call the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com